<SM-436126-A>

5

3-1.Piping

1)

Install so as an air flow coindides with the directional arrows on the cover.

2)

Flush air into the pipe to blow out foregh substances and metal chips before piping.

3)

Leave at least two thread pitches prior to the end of pipe before apllying sealant or

sealing tape to reduce the possibility of contamination or fowling.

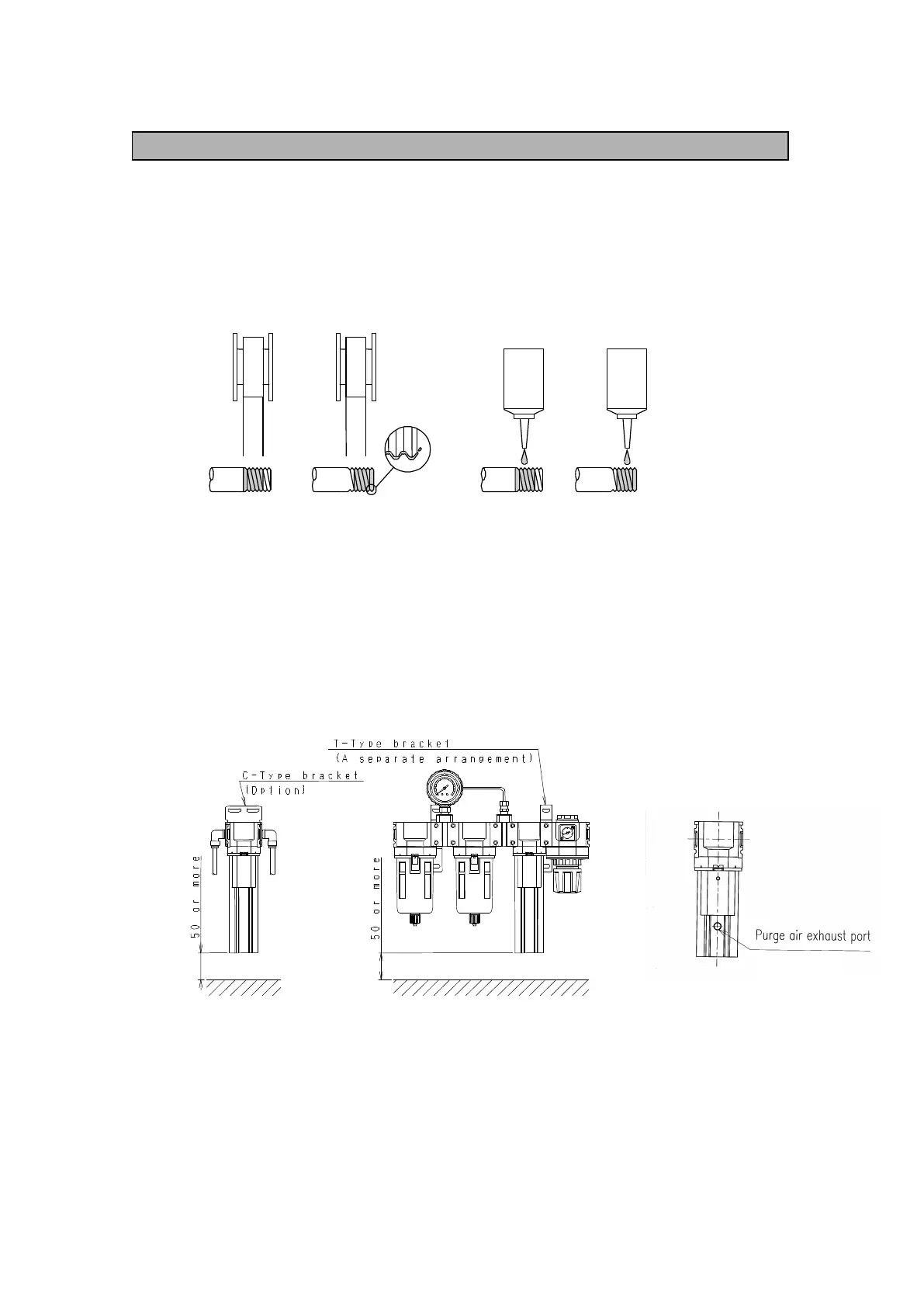

●Seal Tape ●Sealant (Paste)

(Correct) (Incorrect) (Correct) (Incorrect)

Fig.2

3-2.Installation

1)

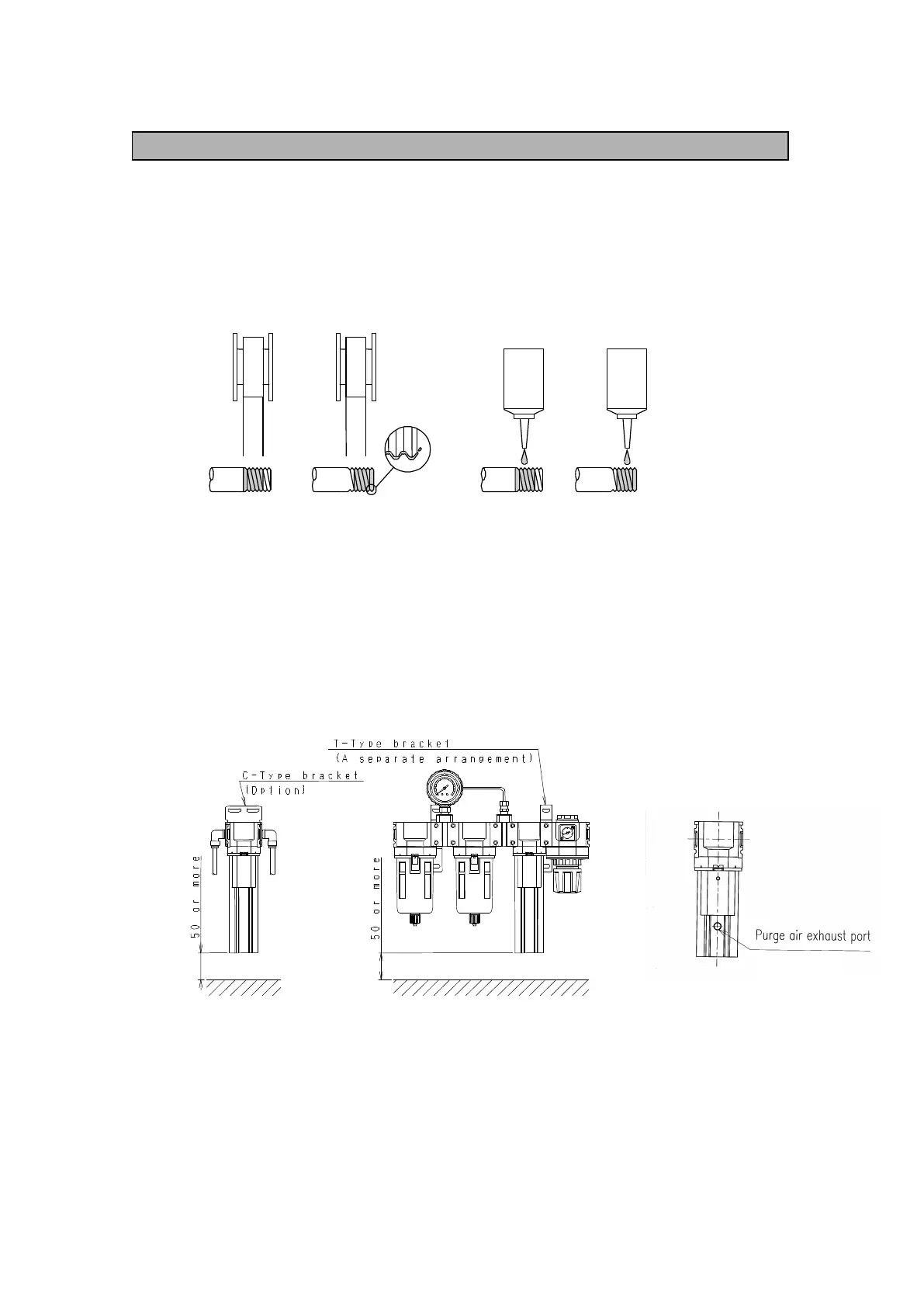

By using C-type bracket of an option, a main part can be directly attached in a

panel etc. In this case, please pipe after inserting C-type bracket in a main

part.(Refer to Fig. 3)

2)

When connecting module of a filter or a regulator before and behind a super drier,

attachment by C-type bracket cannot be performed. Please attach using T-type

bracket. (Refer to Fig. 4)

3)

Please take a maintenance space 50mm or more in the lower part of a super drier.

Fig.3 Fig.4 Fig.5

4)

In case of the option E of SD300-W series, piping of exhaust air should use the

hose or piping material of I.D.5.7 mm or more, and give length as less than 3m.

(Refer to Fig. 5)

5)

In case of the option E of SD400-W series, piping of exhaust air should use the

hose or piping material of I.D.7.2 mm or more, and give length as less than 3m.

(Refer to Fig. 5)

INSTALLATION

INSTALLATIONINSTALLATION

INSTALLATION

(Option E )

Loading...

Loading...