Diversified

Compatible with ow rates of 0.4 to 250 L/min

Compatible with a wide range of ow rates.

Easy ow rate adjustment

(option)

Can be adjusted with a

manual valve.

Handles water up to 95 °C

Molding machine cooling Laser oscillator coolingHeated water for mold

temperature controlling

Water temperature measuring feature

is standard for all models

There is no need to for an external water temperature

sensor, reducing space and wiring work.

Various output functions available

OUT1 OUT2

Analog output

Switch output

NPN/PNP switchable

Pulse output External input

❯

Integrating flow

❯

Integrating flow reset

❯

❯

Instantaneous flow rate

❯

Temperature

Analog output

Switch output

NPN/PNP switchable

Pulse output IO-Link

❯

Integrating flow

❯

Instantaneous flow rate

❯

Temperature

❯

Instantaneous flow rate 1, 2

❯

Temperature 1, 2

❯

Integrating flow

❯

Instantaneous flow rate 1, 2

❯

Temperature 1, 2

❯

Integrating flow

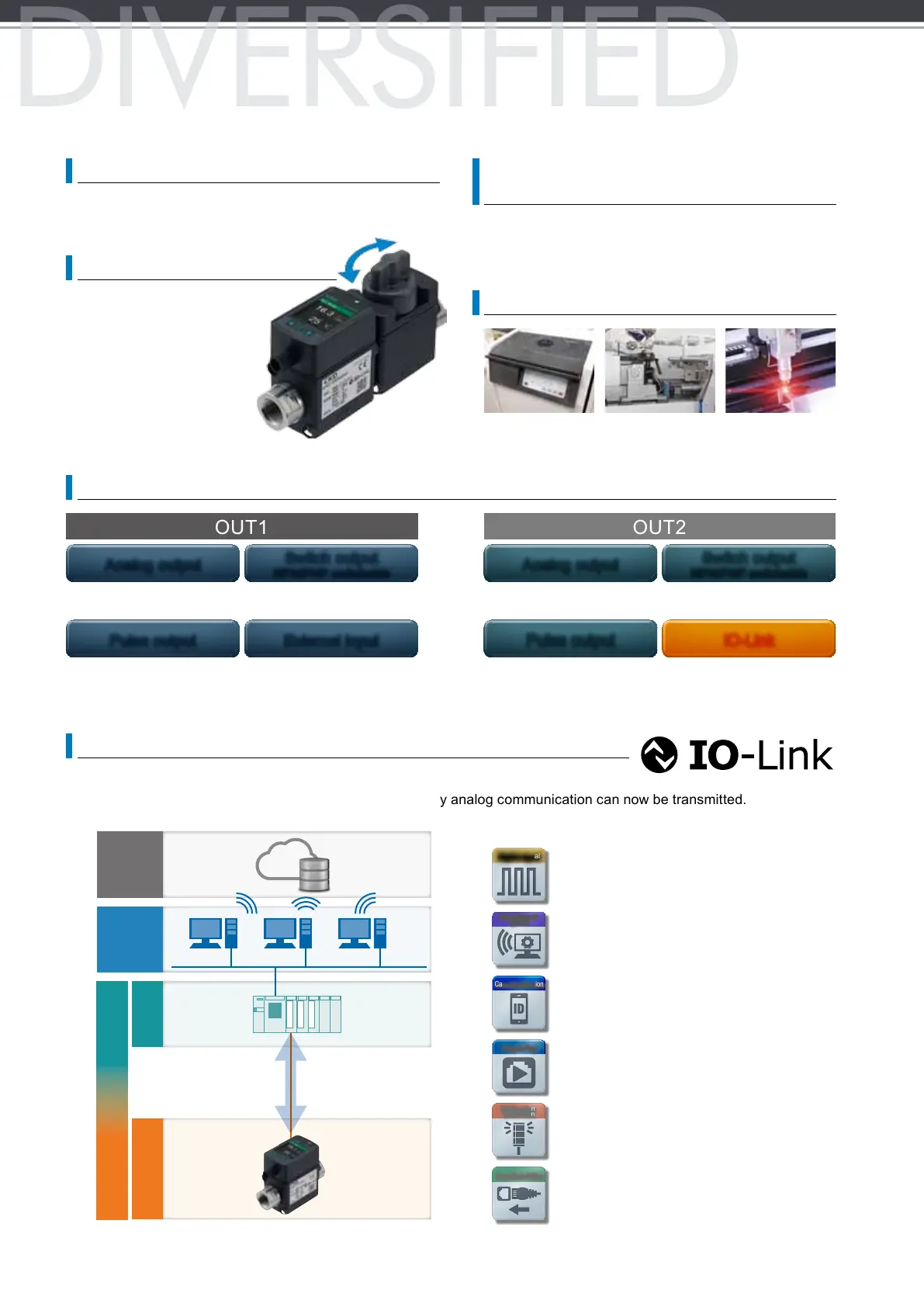

IO-Link model released

IO-Link is a digital communication standard for factory sensors and actuators. (IEC61131-9)

Parameters and event data that could not be transmitted by analog communication can now be transmitted.

Features of IO-Link

Digital signal

Permanent monitoring made possible by

digital data.

Parameter remote

operation

Parameters can be set and changed from

the network, so the system can be operated

remotely.

Case identification

Model No. and serial No. can be checked via

the network.

Plug & Play

Settings can be copied from the master,

making cumbersome resetting of parameters

during maintenance unnecessary.

Malfunction

notification

Malfunctions and disconnections of the device

can be checked.

Connection to fieldbus

Connection to an Ethernet network is possible,

enabling the creation of an IoT system.

Ethernet

Case identification

Parameter change

Permanent monitoring

Alarm notification

Cloud

Plant

Production site

PLC

I/O

Loading...

Loading...