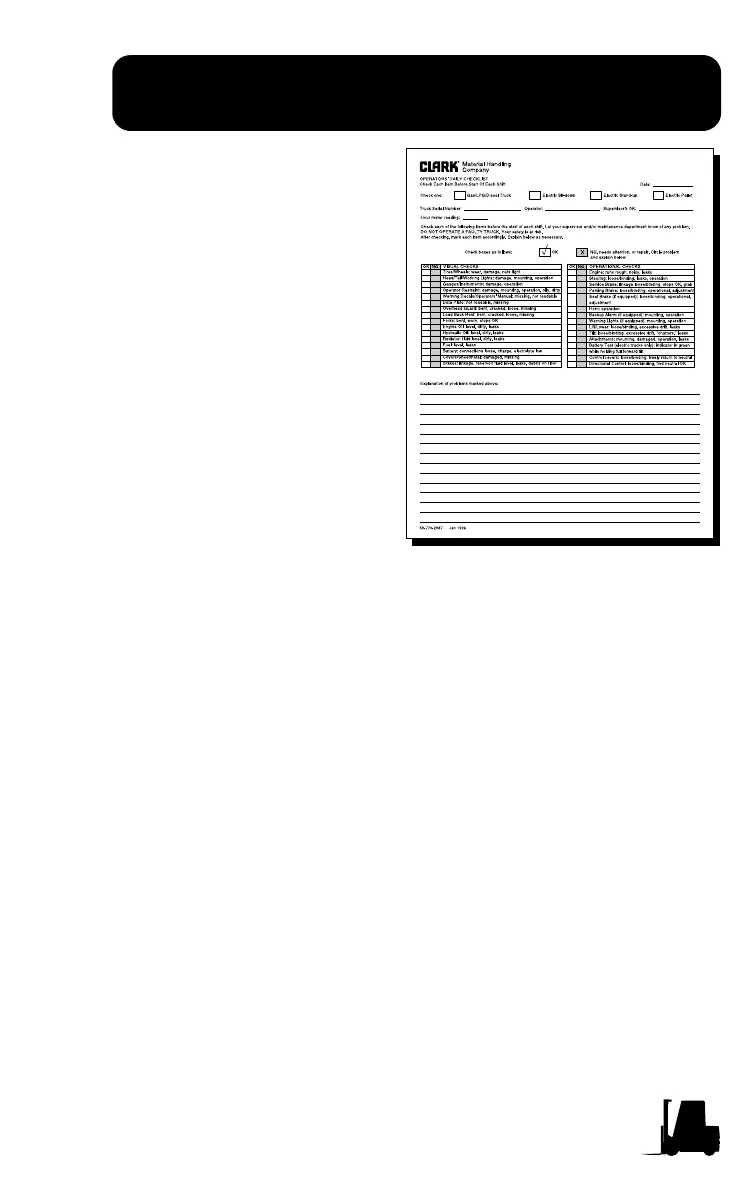

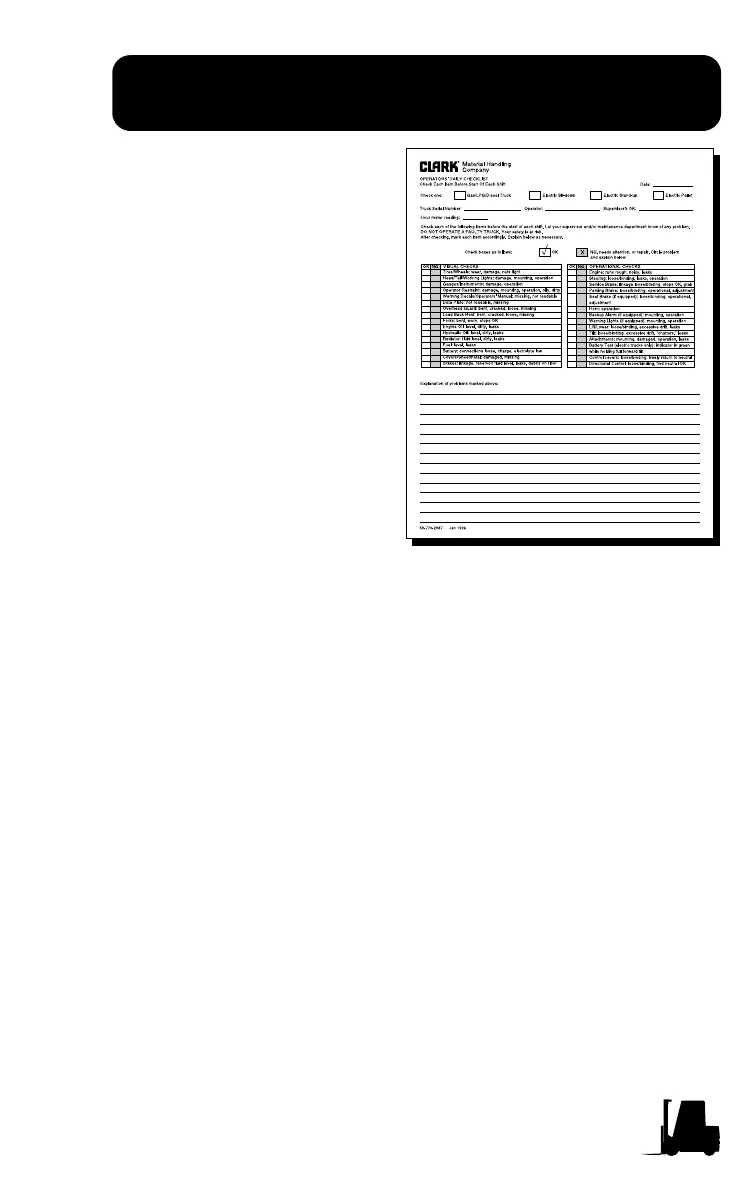

Section 6. Operator Maintenance and Care

Visual Checks 6-3

Visual Checks

First, perform a visual

inspection of the truck and its

ma

jor components:

1. Walk around your lift

tr

uck and take note of

obvious damage that

may have been caused

by operation during the

last shift.

2. Check that all capacity,

sa

fety, and warning

plates or decals are

attached and legible.

3. Check that the battery is

inst

alled and secured in

position correctly. Check

battery connector for safe

condition.

4. Look for any external leakage around drive axle.

5. Check for hydraulic oil leaks and loose fittings. Do not use your

bar

e hands.

6. Be sure that the driver's overh

ead guard and any other safety

devices are in place, undamaged, and attached securely.

7. Check all of the critical components that handle or carry the

load

.

8. Check the upright and lift chains. Check for obvious wear and

main

tenance problems such as damaged or missing parts,

leaks, slack or broken chains, bent parts, and so on.

9. Carefully inspect the load forks for cracks, breaks, bending,

twist

s, and wear. Be sure that the forks are correctly installed

and locked in their proper position.

10. Inspect the wheels and tires for safe mounting and wear condi-

tion.

11. Check the hydraulic sump oil level.

Loading...

Loading...