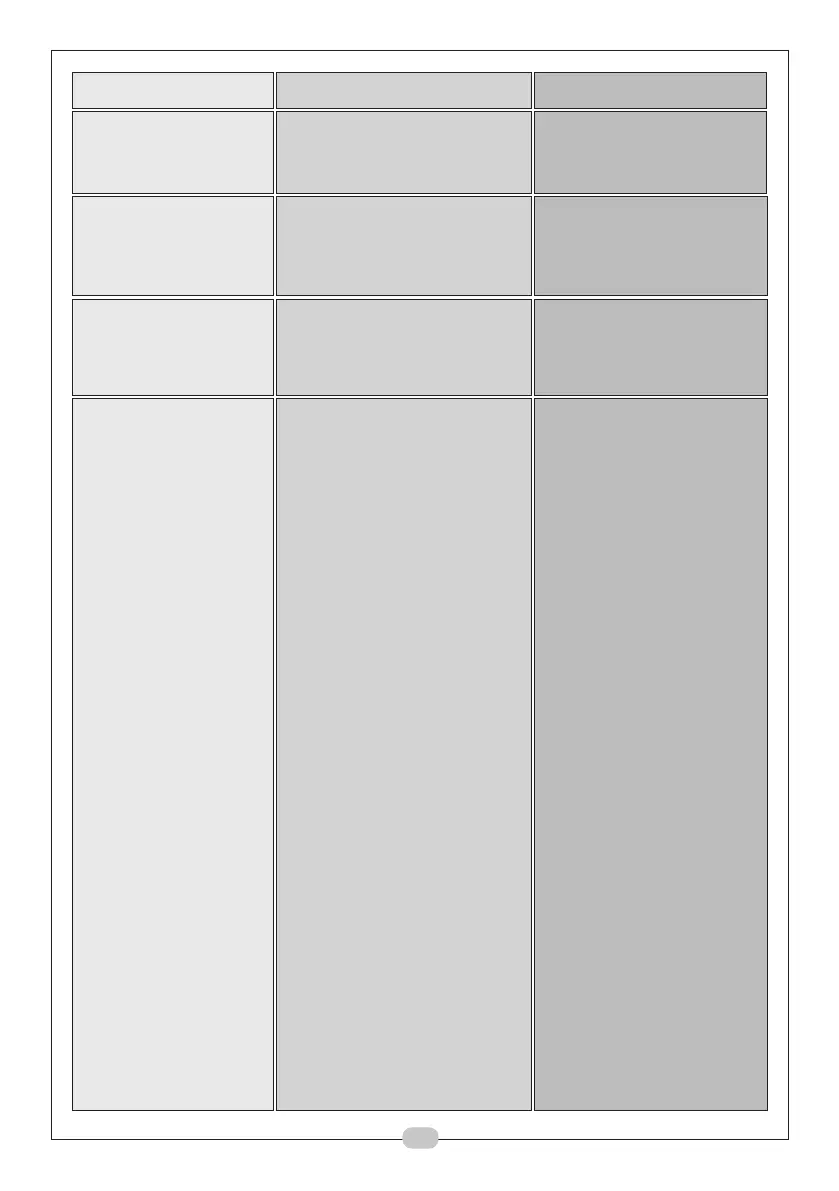

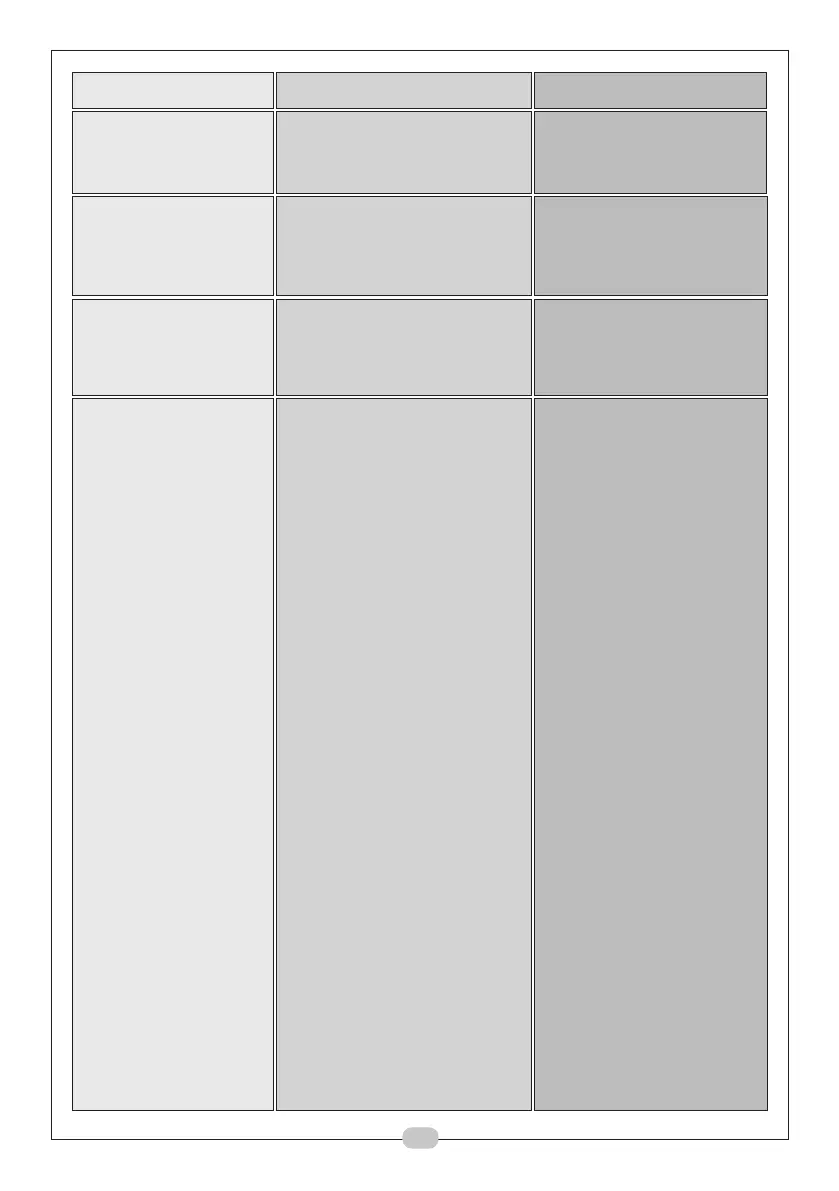

SYMPTOM PROBABLE CAUSES REMEDY

Compressor unit will not Pressure switch defective. Contact Clarke Service

stop automatically. Department

Bleed valve under Non-return valve leaking. Clean non-return valve

pressure switch blows or replace.

whilst compressor is

not running.

Bleed valve under Relief valve leaking. Clean relief valve or

pressure switch change pressure switch.

blows whilst machine

is running.

Compressor runs Suction filter blocked. Change filter.

continuously and can’t V-belt too slack (not Tighten V-Belt.

attain the working applicable to direct

pressure required. drive machines).

Leak between compressor Tighten connection and

block and air receiver/ repair leak or contact

leaks in or near air receiver. Clarke Service Dept

RPM too low because of Contact Clarke Service

incorrectly connected Department

electric motor.

Valves blocked by dirt, Contact Clarke Service

paint, dust or coked up. Department

Inspection cover or plug Empty air receiver and

leaking. change seal or contact

Clarke Service Dept.

Suction rendered difficult or Ensure unobstructed air

impossible at suction intake Flow around the unit.

or the air being taken in is

too warm.

Pressure gauge defective. Install a larger

Unit too small in relation to compressor

air consumption of

connected equipment

Compressor worn. Have compressor over-

hauled or replace it.

10

Loading...

Loading...