10

MAINTENANCE

The only maintenance required is a regular inspection to ensure that leaves

and other debris is not blocking the passage of water through the pump.

If you suspect the pump is blocked by mud, silt, leaves etc, disconnect it from

the mains supply and backflush to clear any blockage though the drain plug.

Always keep the pump in a clean condition, checking regularly for loose bolts

or a damaged power cable etc.

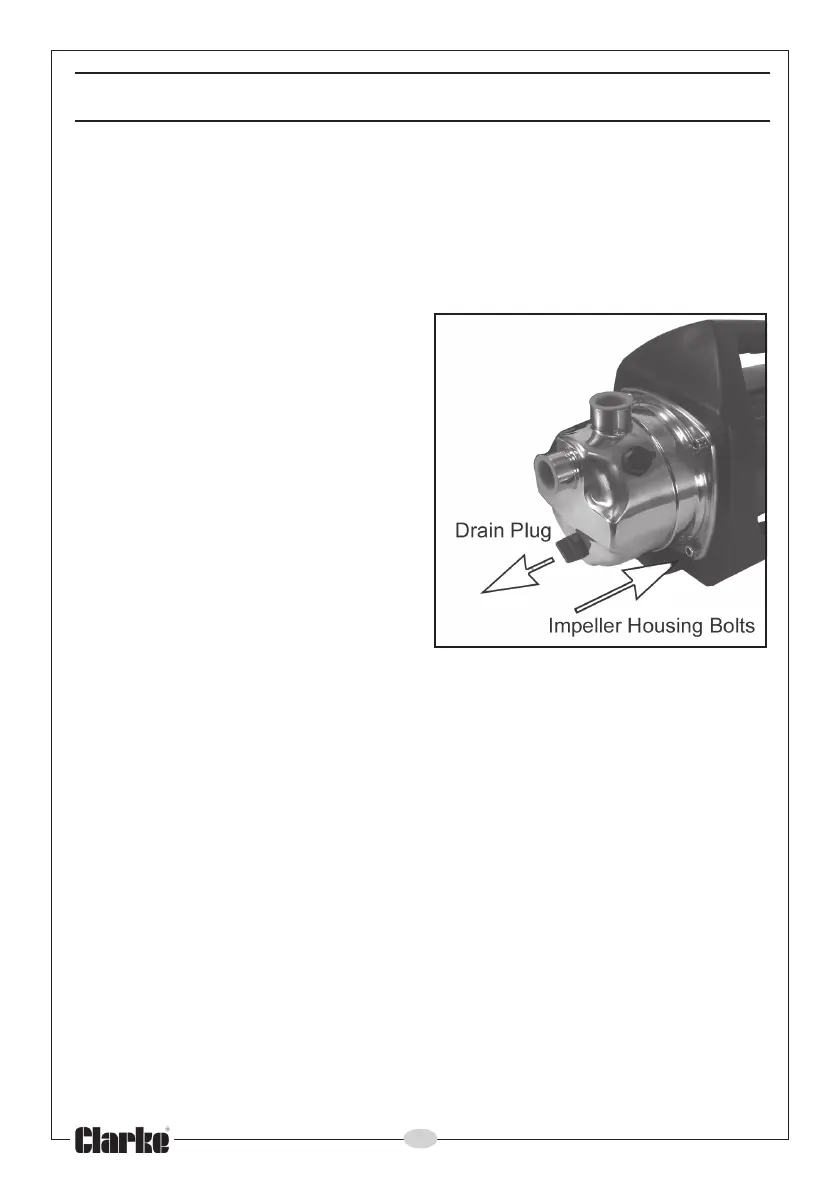

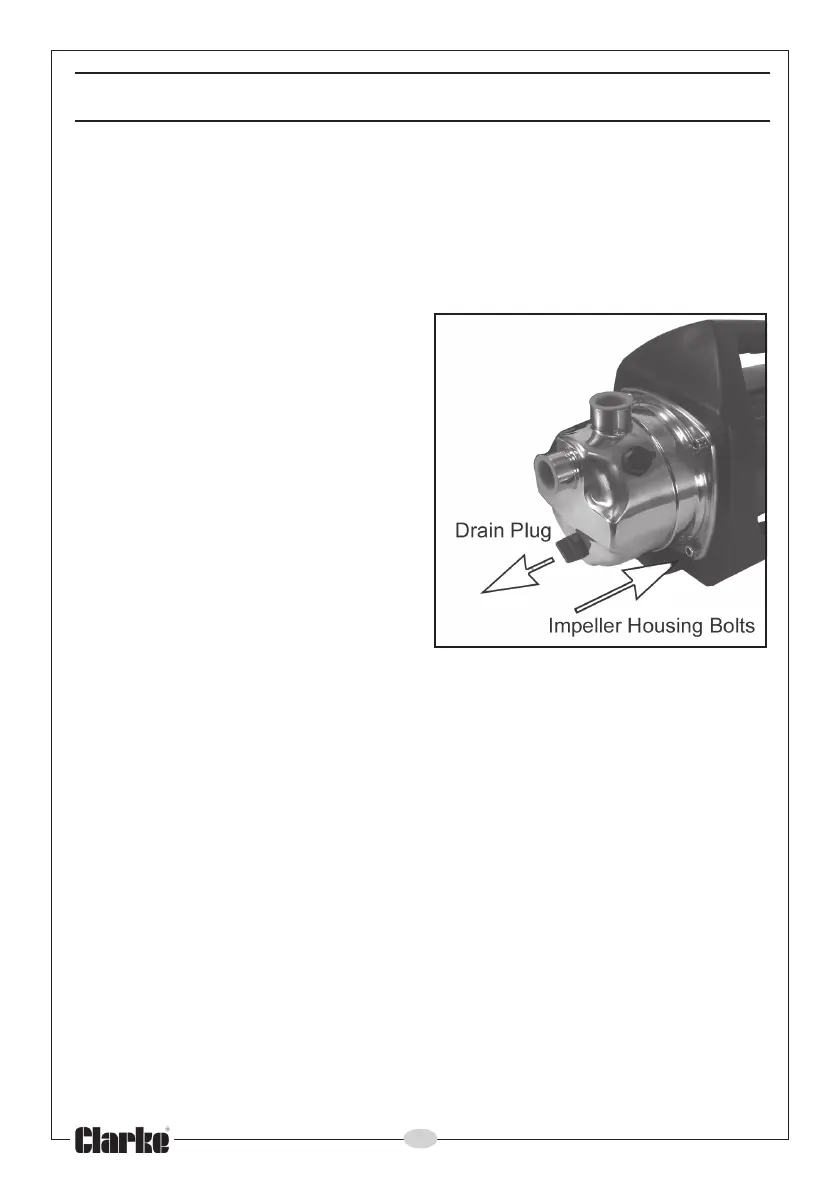

If the pump has been used under

arduous conditions leading to

internal fouling or damage, the

impeller housing can be removed by

undoing the four socket-headed

impeller housing bolts shown in Fig 4.

The impeller can then be inspected

for damage.

• Note that the SPE1200SS pump

also includes a 13mm hexagonal

connector used to extend the

bolts between pump & motor

housing (item 25 on p16).

STORAGE

After use, drain the pump body

whenever there is danger of freezing. If the pump has been used with

contaminated or salty water, it should be thoroughly flushed with clean water

following use, both inside and out. It should then be drained before replacing

the drain plug and storing in a clean dry environment not exposed to the

weather.

In the event that dismantling and overhaul of the pump is necessary, contact

your CLARKE International Service Department on 020-8988-7400.

ACCESSORIES

A wide range of accessories is available, including Filters, Foot Valves, Hoses,

Couplings and 90

° Hose Adaptors, etc. Contact your Clarke dealer for further

information or Clarke International Sales Department on 01992 565333.

These pumps are supplied with a 1” male 90° hose adaptor.

The use of parts other than genuine Clarke replacement parts may result in

possible safety hazards or decreased machine performance, and will

invalidate your warranty.

Fig 4

Loading...

Loading...