OPERATOR'S MANUAL

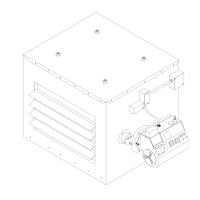

CLEAN BURN MODELS: CB-1500 and CB-2500 MULTI-OIL FURNACES

with CB-500 Series Burner

PUBLICATION DATE: 6/1/10, Rev. 4 CLEAN BURN PART # 43161

WARNING: DO NOT assemble, install, operate, or maintain this equipment without first

reading and understanding the information provided in this manual. Installation and

service must be accomplished by qualified personnel. Failure to follow all safety precautions

and procedures as stated in this manual may result in property damage, serious personal injury

or death.

CLEAN BURN, INC. • 34 Zimmerman Road • Leola, PA 17540 • U.S.A.

Copyright © 2009 Clean Burn, Inc. All rights reserved. No part of this publication may be reproduced, or distributed without

the prior written permission of Clean Burn, Inc. 34 Zimmerman Road, Leola, PA 17540. Subject to change without notice.

The Clean Burn logo is a trademark of Clean Burn, Inc. All other brand or product names mentioned are the registered

trademarks or trademarks of their respective owners.

230 V / 50 Hz

I88942

FOR YOUR SAFETY -

DO NOT STORE GASOLINE

OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY APPLIANCE!!

2

2

0

-

2

4

0

5

0

-

6

0

H

z

3

W

t

s

1

0

s

T

y

p

e

B

H

O

6

4

N

r

.

0

5

7

H

7

0

3

6

D

a

n

f

o

s

s