CB780E/CB784E RELAY MODULES WITH VALVE PROVING

750-234 19 32-00150—03

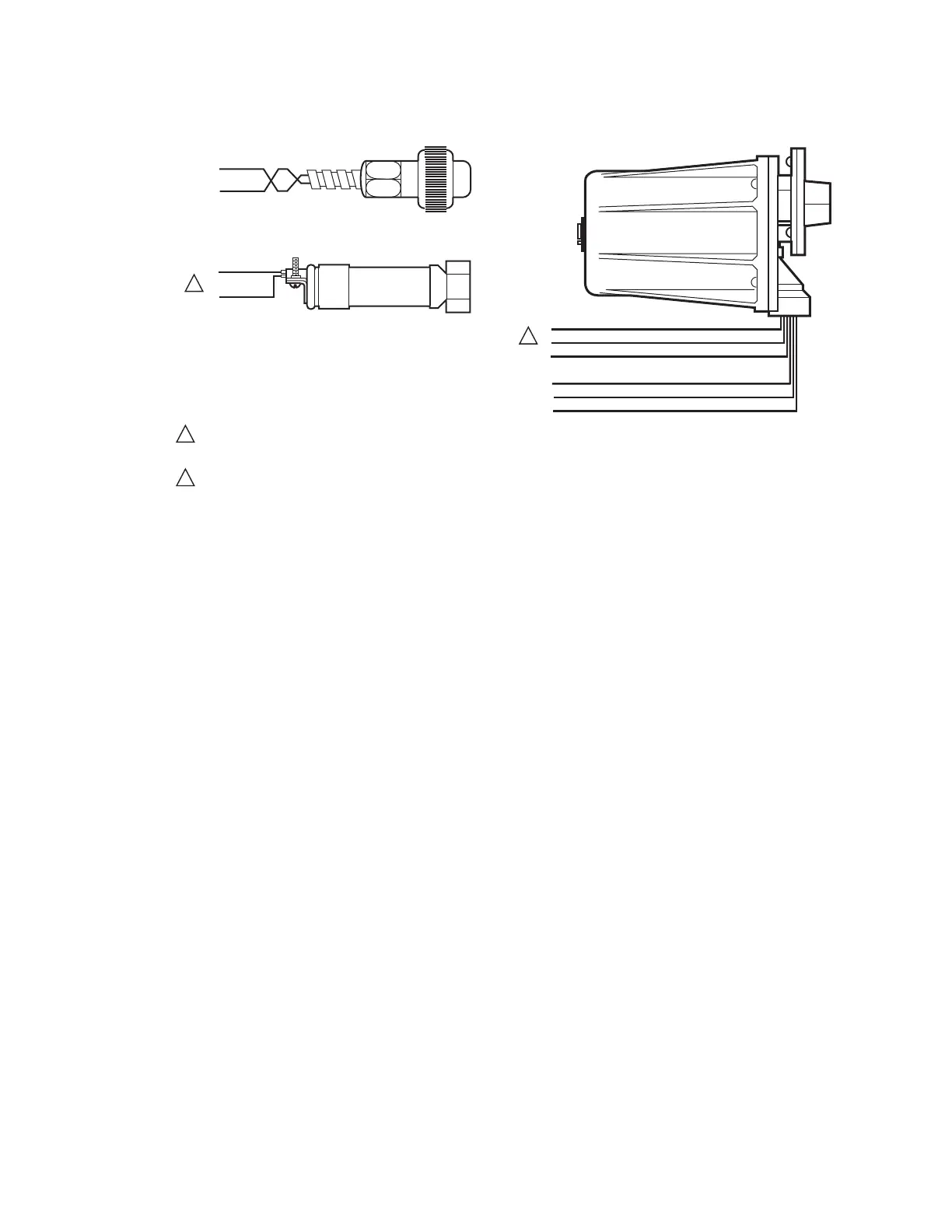

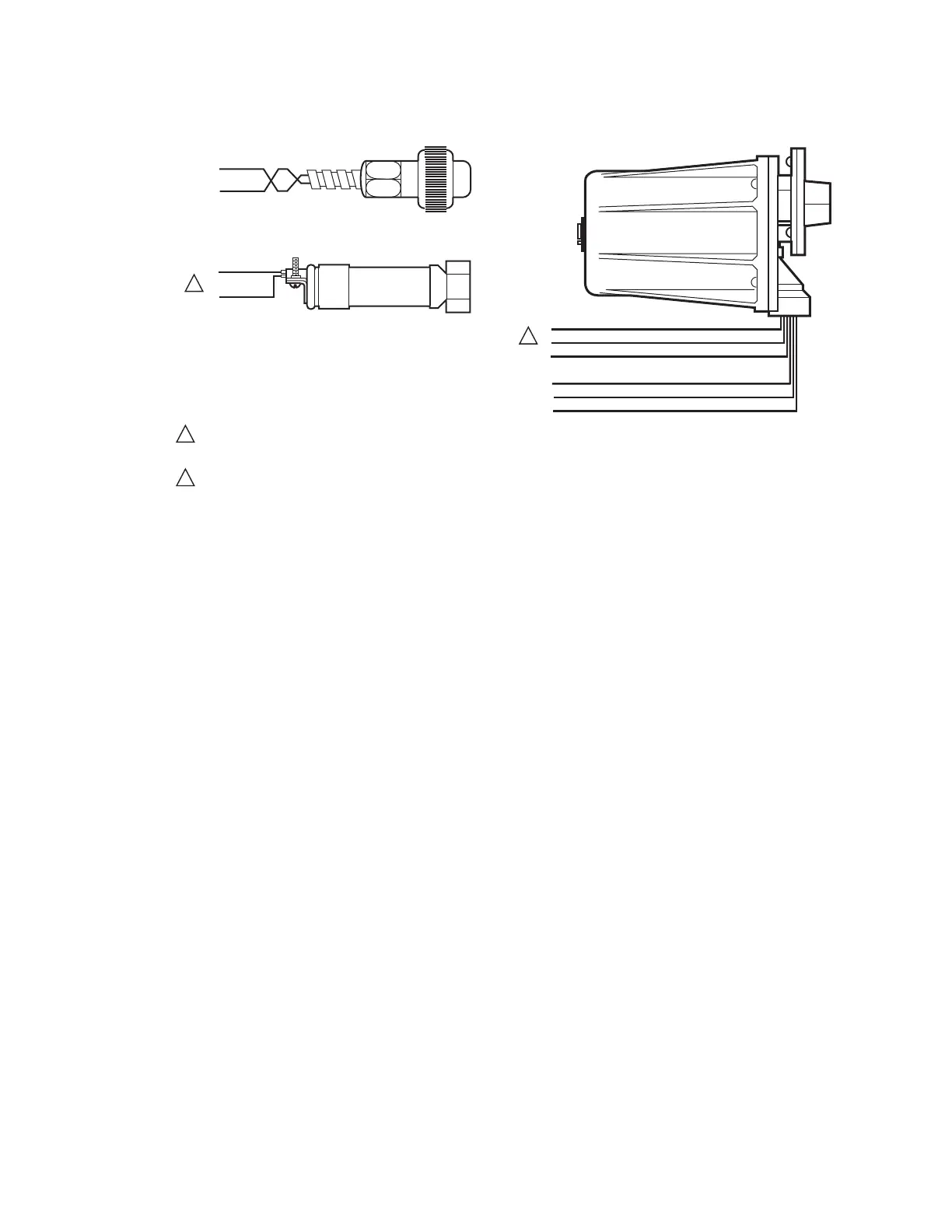

Fig. 20. Flame detector wiring.

VALVE PROVING SYSTEM

The Valve Proving System feature provides a systematic

way of testing the valve seat integrity to assure the valves

are in the closed state whenever the sequence of

operation requires them to be closed. It is designed to

detect a leak greater than 0.1% of the burner input

capacity. For example, a 10 million Btu/hr natural gas-

fueled burner would have a fuel input capacity of

approximately 1,000 ft

3

/hr. A leak rate greater than 0.1%

of 1,000 ft

3

/hr or 1 ft

3

/hr in either valve will be detected

with the Valve Proving System. Smaller leaks will not be

detected.

At commissioning time, the Valve Proving System may be

scheduled to occur at one of five different times: Never,

Before, After, Both, and Split.

Never—Device default as received: in this case Valve

Proving does not occur.

Before—Valve Proving occurs concurrently with Pre-

Purge.

After—Valve Proving occurs after the Run state before

the internal Safety Relay dropout state and concurrent

with Post Purge (if configured).

Both—Valve proving occurs at both times Before and

After noted above.

Split—The downstream seat (high pressure) test is per-

formed at the Before time and the upstream seat (low

pressure) test is performed during the After time.

The Valve Proving items programmed are:

1. Specify when to perform Valve Proving. Demand

input to terminal 17 actually enables the function of

Valve

Proving.

2. Specify the time duration of the test (calculated from

Appendix A).

BLUE

YELLOW

WHITE

WHITE

BLACK

BLACK

F

G

22

L2

L1

L2

M28588A

BLUE

WHITE

BLUE

WHITE

F

G

F

G

INFRARED (817-4133)

ULTRAVIOLET (817-1743)

SOLID STATE SELF-CHECKING

ULTRAVIOLET (817-1121)

1

2

1

FLAME DETECTOR LEADS ARE COLOR CODED. THE BLUE LEAD MUST BE CONNECTED TO THE F TERMINAL AND THE WHITE

MUST BE CONNECTED TO THE G TERMINAL. THE UV SENSING TUBE IS POLARITY SENSITIVE. REVERSING THE LEADS EVEN

MOMENTARILY CAN DAMAGE OR DESTROY THE UV TUBE.

FLAME DETECTOR LEADS ARE COLOR CODED. THE BLUE LEAD MUST BE CONNECTED TO THE F TERMINAL AND THE YELLOW

MUST BE CONNECTED TO THE G TERMINAL. THE UV SENSING TUBE IS POLARITY SENSITIVE. REVERSING THE LEADS EVEN

MOMENTARILY CAN DAMAGE OR DESTROY THE UV TUBE.

2

Loading...

Loading...