CB780E/CB784E RELAY MODULES WITH VALVE PROVING

750-234 47 32-00150—03

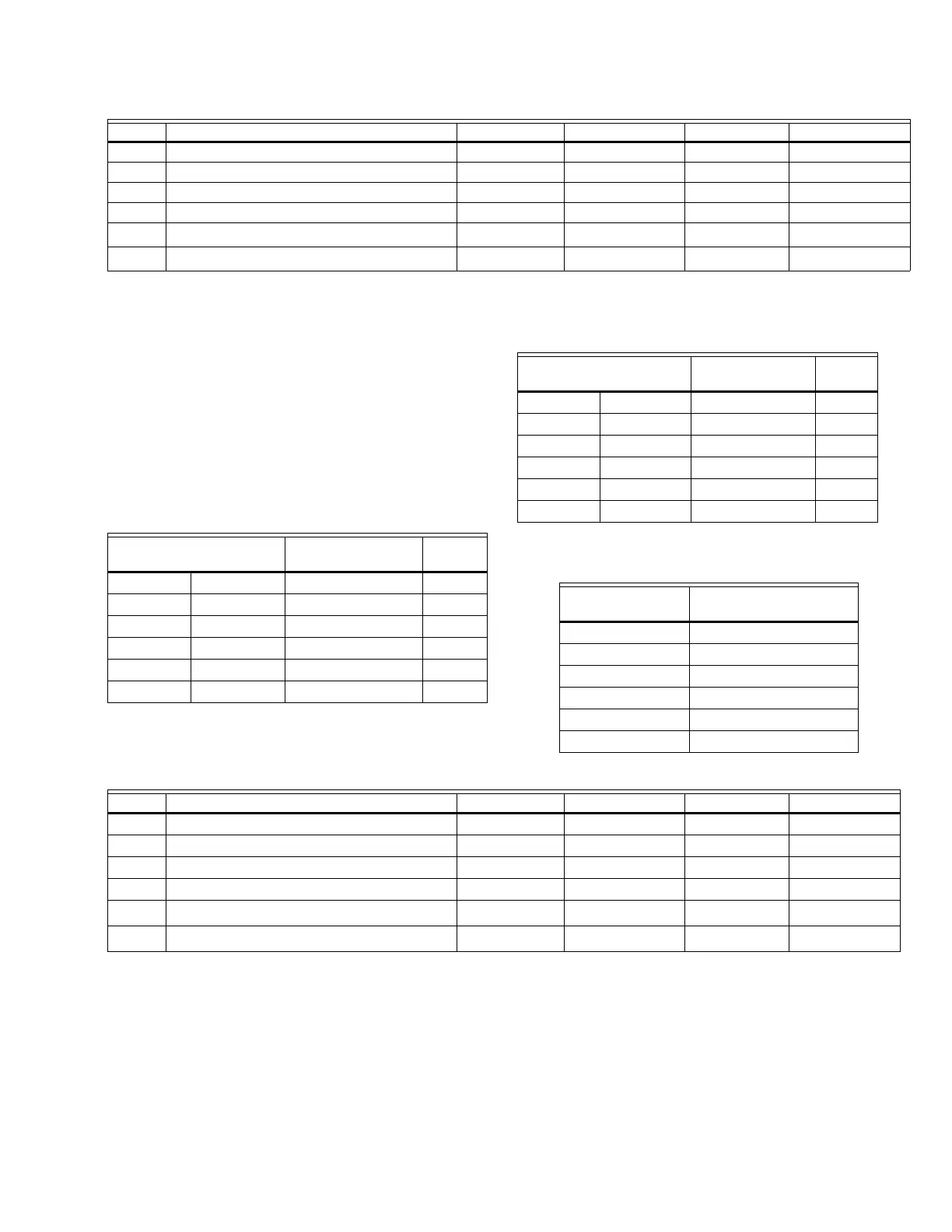

Table 16. VPS Worksheet Example.

a

Divide inches w.c. by 27.7 to get psi.

b

Divide Btuh by 1000 to get cf/hr for natural gas or by 2550 to get cf/hr for LP gas.

Calculation of Valve Train Volume:

X = V1 + V2 + (A x L ÷ 144)

X = 0.0218 + 0.0238 + (3.356 x 1.75 ÷ 144) = 0.0864.

Calculation of Valve Proving Test Time:

Test Time = 187,000 x (P x X ÷ C)

Test Time = 187,000 x (2 x 0.0864 ÷ 2500) = 12.9 sec.

Round up to 13 seconds; enter 13 seconds into the VPS

Setup.

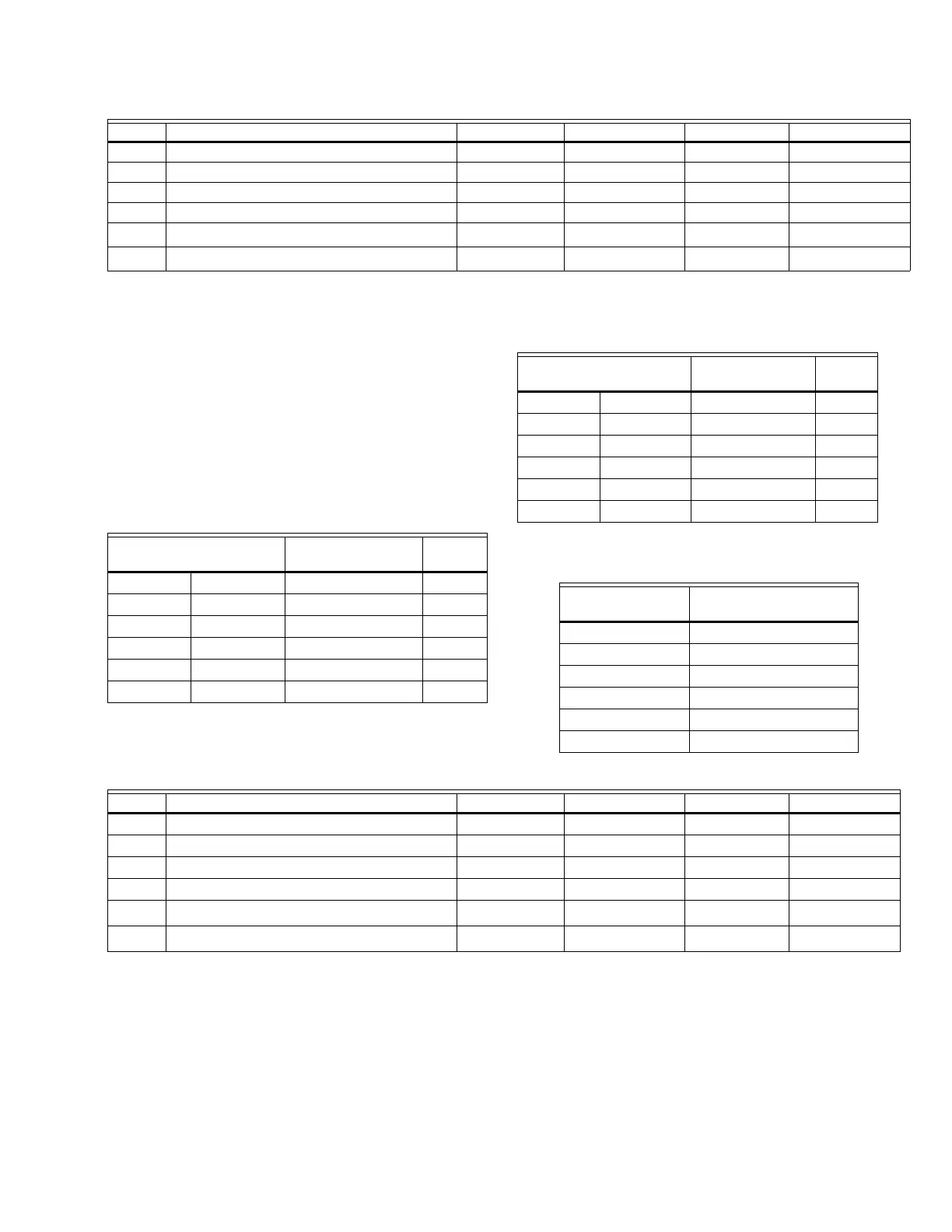

Table 20. VPS Worksheet.

a

Divide inches w.c. by 27.7 to get psi.

b

Divide Btuh by 1000 to get cf/hr for natural gas or by 2550 to get cf/hr for LP gas.

Item Description Information Lookup Table Results Formula Item

V1 Upstream Valve Volume 940-04544 17 0.0218 V1

V2 Downstream Valve Volume 940-04539 18 0.0238 V2

D Pipe Size NPT (in.) 2 in. NPT 19 3.356 A

L Pipe Length (ft) 1.75 ft — 1.75 L

P

Valve Inlet Pressure (psig)

a

2— 2P

C

Burner Maximum Firing (cf/hr)

b

2.5 mbtu — 2500 C

Table 17. V1 Upstream Volumes for Valves.

Models

Pipe Size NPT

(inches) Size

On/Off POC

940-04543 1-1/2 0.0218

940-04539 940-04544 2 0.0218

940-04540 940-04545 2-1/2 0.0227

940-04541 940-045262 3 0.0227

940-04409 940-04451 4 0.0779

Table 18. V2 Downstream Volumes for Valves.

Models

Pipe Size NPT

(inches) Size

On/Off POC

940-04543 1-1/2 0.0238

940-04539 940-04544 2 0.0238

940-04540 940-04545 2-1/2 0.0245

940-04541 940-045262 3 0.0245

940-04409 940-04451 4 0.0801

Table 19. Schedule 40 Pipe Internal Cross-Sectional

Area.

Pipe Size NPT

(Inches)

Cross-Sectional Area

(Sq. In.) “A”

1-1/4 1.498

1-1/2 2.036

23.356

2-1/2 4.788

37.393

4 12.730

Item Description Information Lookup Table Results Formula Item

V1 Upstream Valve Volume 17 V1

V2 Downstream Valve Volume 18 V2

D Pipe Size NPT (in.) 19 A

LPipe Length (ft) — L

P

Valve Inlet Pressure (psig)

a

—P

C

Burner Maximum Firing (cf/hr)

b

—C

Loading...

Loading...