MODELS 1028 & 1042 BLAST MACHINES Page 10

© 2013 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 04124, Rev. K

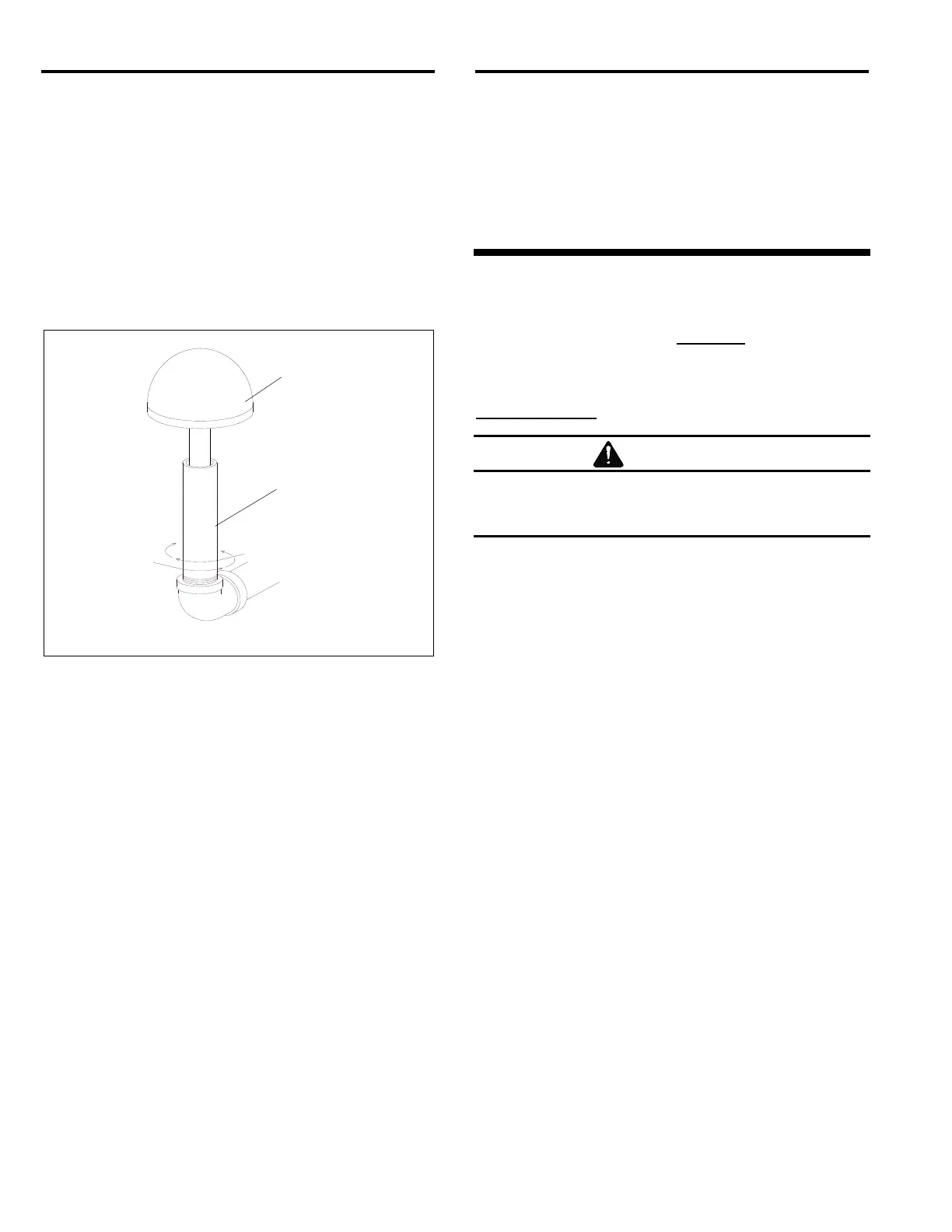

5.3.2 To gain access to the pop-up valve, remove the

inspection door assembly.

5.3.3 Using a small pipe wrench, unscrew the pop-up

valve guide by turning it counterclockwise. Remove the

pop-up valve and guide from the machine.

5.3.4 While the pop-up valve is out, check alignment.

A misaligned pop-up valve could result in early valve

failure, or abrasive leakage when the machine is

pressurized or depressurized.

Figure 3

5.3.5 Slide the new pop-up valve into the guide, and

then screw the valve guide (with the pop-up valve in it)

into position inside the machine. Tighten the guide until

wrench-snug, but not wrench-tight. Over-tightening the

guide will make it difficult to remove the next time the

pop-up valve needs replacement.

5.3.6 Put a new gasket on the inspection door

assembly before bolting the door onto the machine.

5.4 Replacing the Pop-Up Seal

5.4.1 All service on the blast machine must be done

with the compressed air off and the air supply locked-out

and tagged-out.

5.4.2 If unable to change the seal using the following

methods, or if the seal falls inside the machine, remove

the inspection door and work from inside the machine.

5.4.3 Remove the old seal using fingers, screwdriver,

or similar object, to work the seal out of the retaining

groove.

5.4.4 Push the new seal all the way through the port

and then fit it into the retaining groove. For the last few

inches, pull up on the seal and allow it to pop into position.

6.0 TROUBLESHOOTING

NOTE: This section only identifies conditions and

problems in the blast machine. Always refer to the

appropriate section of this manual, or manuals for

the remote controls or other accessory equipment,

before servicing the equipment.

WARNING

To avoid serious injury when troubleshooting

the machine, turn off the compressed air, and

lockout and tagout the air supply.

6.1 Neither abrasive nor air comes out of the

nozzle while the machine is under pressure

6.1.1 Depressurize the blast machine. After the pop-

up valve has dropped, remove the nozzle, and check for

obstruction.

6.1.2 Make sure that both the abrasive metering valve

and choke valve are open.

6.2 Air only (no abrasive) comes out the nozzle

6.2.1 Abrasive metering valve may be closed or

needs adjustment. Adjust the metering valve per Section

3.5.

6.2.2 Blast machine may be empty.

6.2.3 Abrasive may be damp. Refer to Section 5.1 to

clear damp abrasive.

6.2.4 There may be an obstruction in the machine.

Check for obstructions per Section 5.2.

6.3 Heavy abrasive flow

6.3.1 Make sure the choke valve is open. The valve is

open when the handle is in-line with the piping.

6.3.2 Abrasive metering valve may be open too far.

See Section 3.5.

Loosen

Tighten

Pop-up Guide

Pop-up Valve

Loading...

Loading...