MODELS 1028 & 1042 BLAST MACHINES Page 3

© 2013 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 04124, Rev. K

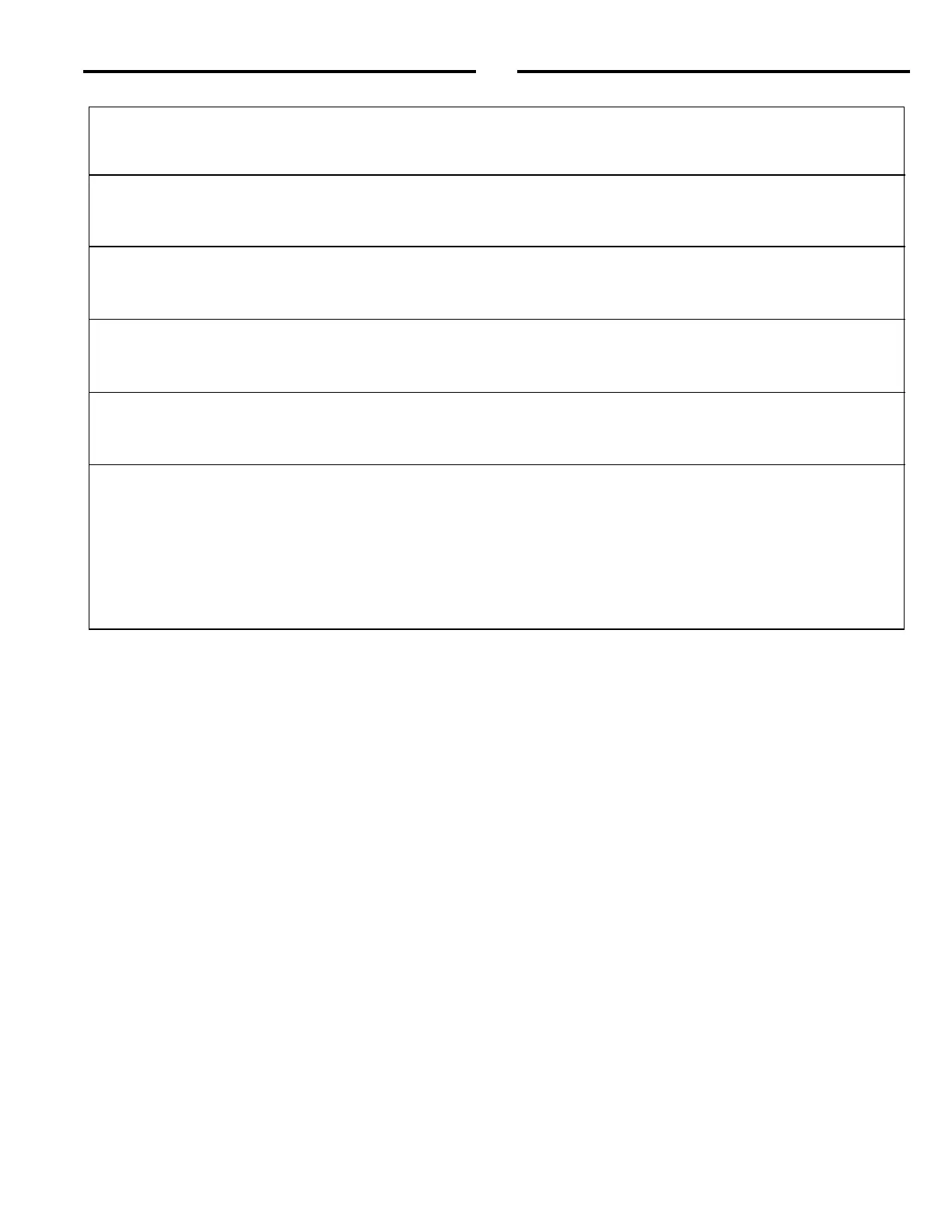

Compressed Air and Abrasives Consumption

Consumption rates are based on abrasives that weigh 100 pounds per cubic foot

Pressure at the Nozzle (psi) Air, Power

Nozzle and Abrasive

Orifice Size (inch) 50 60 70 80 90 100 Requirements

11 13 15 17 19 20 Air (cfm)

No. 2 (1/8 inch) 67 77 88 101 112 123 Abrasive lbs/hr)

2.5 3 3.5 4 4.5 5 Compressor (hp)

26 30 33 38 41 45 Air (cfm)

No. 3 (3/16 inch) 150 171 196 216 238 264 Abrasive (lbs/hr)

6 7 8 9 10 10 Compressor (hp)

47 54 61 68 74 81 Air (cfm)

No. 4 (1/4 inch) 268 312 354 408 448 494 Abrasive (lbs/hr)

11 12 14 16 17 18 Compressor (hp)

Air requirements were measured by a flow meter under actual blasting conditions, and are therefore lower than figures

for air alone, with no abrasive.

Horsepower requirements are based on 4.5 cfm per horsepower.

Figures are for reference only, and may vary for different working conditions. Several variables, including metering valve

adjustments, can affect abrasive flow.

Figures show approximate compressed air and abrasive consumption when nozzles are new. Consumption will increase

as the nozzle wears.

Figure 2

and is under such positive control that the pressure

in the vessel cannot exceed the maximum allowable

working pressure at the operating temperature...".

OSHA regulation 1910.169 refers to the above ASME

code when describing the necessity of pressure relief

valves on compressed air equipment. DO NOT operate

blast machines with air compressors that are not

equipped with properly functioning pressure relief

valves.

(1)

American Society of Mechanical Engineers, Boiler and Pressure

Vessel Code, 1989

(2)

Occupational Safety and Health Administration, 29 CFR 1910,

Subpart M - Compressed Gas and Compressed Air Equipment.

1.3.6 Compressed-air Requirements

1.3.6.1 The size of the compressor required depends on

the orifice size of the nozzle and blasting pressure.

Unless otherwise specified, blast machine packages are

supplied with a 1/4" orifice nozzle. Nozzles larger than

1/4" are not recommended because they will rapidly

wear the 1/2" blast hose used with these machines.

1.3.6.2 Refer to the table in Figure 2 to determine cfm

requirements. The table shows air consumption of

nozzles when new. It does not show the recommended

compressor size. As nozzles wear, they will consume

70% to 80% more air. Consult with a compressor

supplier for suggested compressor size based on the air

consumption of the next larger orifice size.

1.3.7 Remote Controls

1.3.7.1 Separate manuals are provided for the

operation, maintenance, and replacement parts for the

TLR-50 remote controls (Manual Stock No. 03358) and

RLX control handle (Manuals Stock No. 10574). Refer to

those manuals for set-up and operation of the remote

control system.

1.3.8 Air Filter, Optional

1.3.8.1 The optional air filter at the blast machine inlet

removes water condensed in the compressed air line. Its

use is especially important in areas of high humidity, or

when fine-mesh abrasive is used. Moisture causes

media to clot and inhibits free flow through the metering

valve. See Section 7.1 for accessories. If moisture

problems persist, an air dryer may be required.

Loading...

Loading...