INEX SUCTION BLAST CABINET With VACUUM COLLECTOR Page 2

© 2005 CLEMCO INDUSTRIES CORP. • www.clemcoindustries.com • Manual No11217 Rev. E 03/05

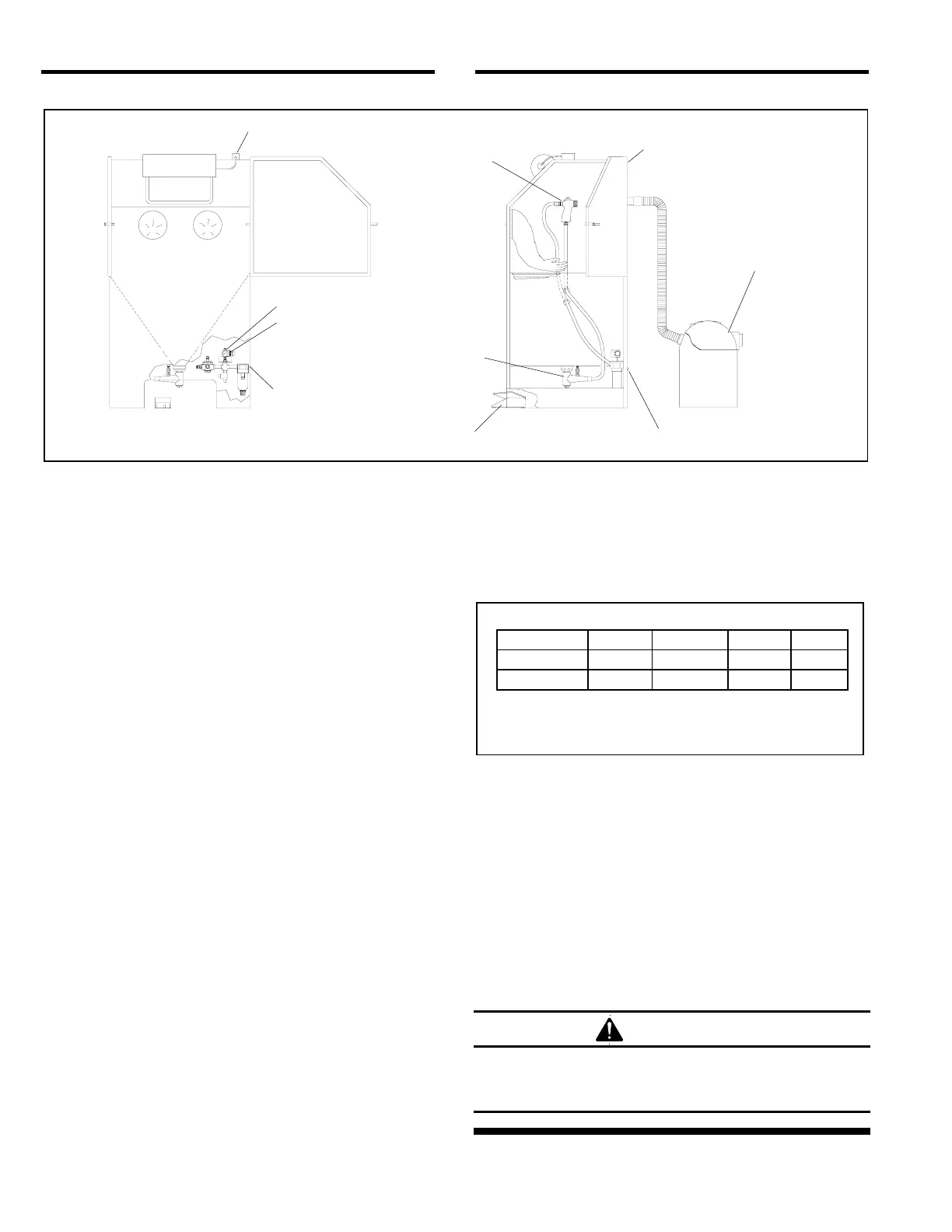

Figure 1

are based on standard 5/16″ orifice nozzle (5/32″ air jet)

and average conditions. As a rule, larger nozzles deliver

more media, thus demand greater air movement though

the cabinet. With larger nozzles, the maximum size of

media decreases from those recommended. Media finer

than those recommended may decrease visibility.

1.6.2 Steel: Fine steel grit or shot may be used.

However, care must be taken to prevent ricocheting

abrasive from peening the cabinet weldment.

1.6.3 Sand and Slag: Sand should never be used

because of the respiratory hazards associated with

media containing free silica. Slags are not recommended

because they rapidly break down.

1.6.4 Silicon Carbide, Aluminum Oxide, and

Garnet: These are the most aggressive, high volume

abrasive in the blasting industry. Aggressive media such

as these may be used, but the service life will be

reduced on any equipment components which come in

contact with the abrasive. To avoid unscheduled down

time, periodically inspect the nozzle, media hose,

conveying hose, and filter for abrasive wear. Nozzles

lined with boron carbide are recommended to extend

nozzle wear life. See Section 8.2.

1.6.5 Glass Bead: Most beads are treated to ensure

free-flow operation even with moderately high humidity.

Glass beads subjected to moisture may be reused after

thorough drying and breaking up of any lumps.

1.7 Compressed Air Requirements

1.7.1 The size of the compressor required to operate

the cabinet depends on the size of the air jet and

blasting pressure. Unless specified otherwise, cabinets

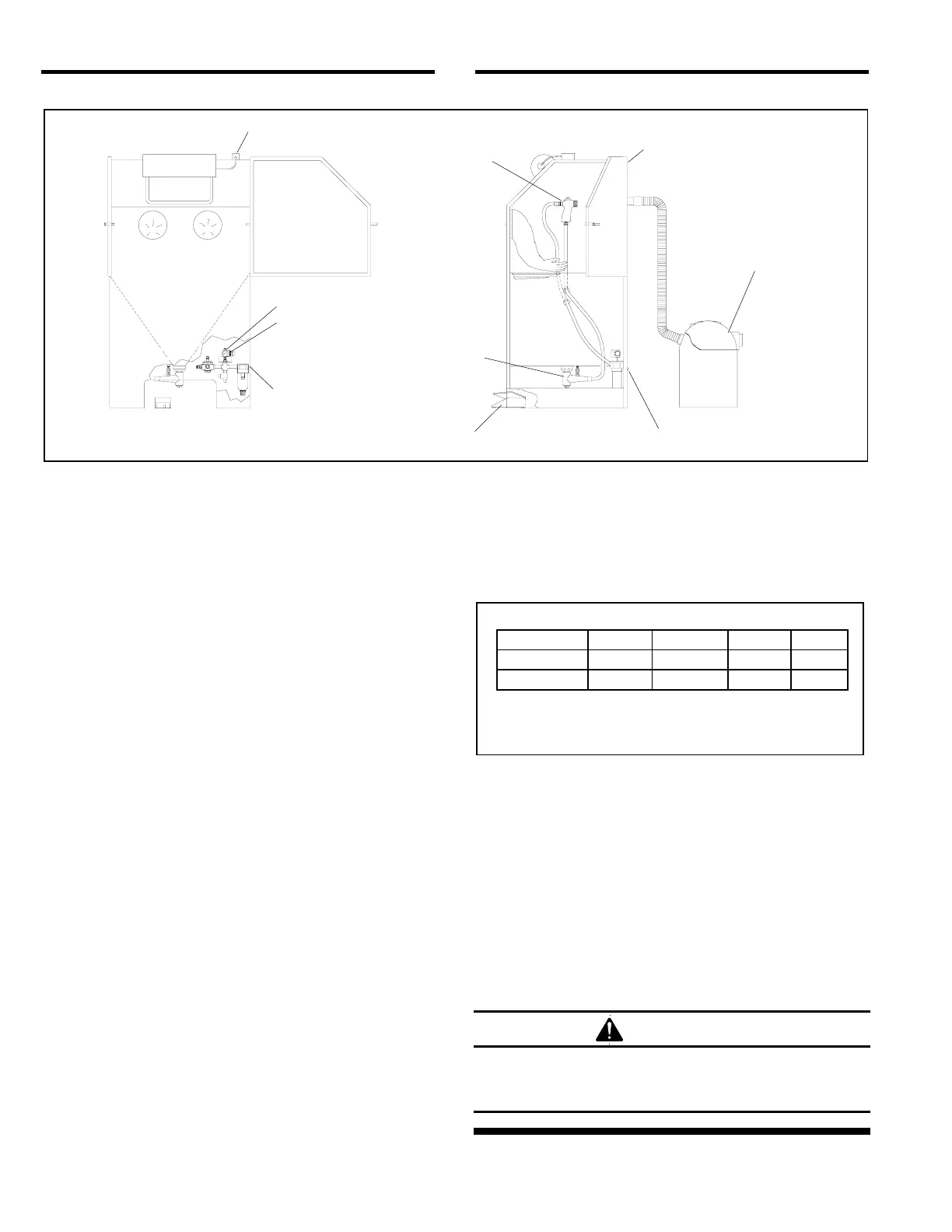

are supplied with a No. 5 (5/32" orifice) jet. See table in

Figure 2 to determine cfm requirements. Consult with a

compressor supplier for suggested compressor size

based on the air consumption.

BNP Gun Jet Nozzle CFM PSI

No. 4 1/8" 5/16" 21 80

No. 5 5/32" 5/16" 32 80

No. 6 3/16" 3/8" 47 80

Air Consumption in cfm

Figure 2

1.7.2 The air filter at the air inlet connection, reduces

condensed water from the compressed air. Its use is

especially important in areas of high humidity, or when

fine-mesh media are used. Moisture causes media to

clot and inhibits free flow through the feed assembly. If

moisture problems persist, an air dryer may be required.

1.8 Electrical Requirements

1.8.1 The system requires 120-VAC, 1-Ph, 60-Hz,

with 15 Amps service. A power cord is supplied. No

additional wiring is required.

WARNING

Do not use electrical adaptors that eliminate the

ground prong on 120-volt plugs. Doing so can

cause electric shock and equipment damage.

Metering Valve

Foot Pedal

Vacuum

Collector

On-Off Switch

BNP Blast Gun

Pilot Regulator

Pressure Gauge

Air Inlet Duct

Air Filter

Compressed air inlet

Grounding Lug

Loading...

Loading...