9

4 - WATER CONNECTIONS

4.4 CONDENSE DRAIN

The condense must be disposed of in order to avoid

damaging things and persons.

• Unit drain coupling: the connection must not transmit

mechanical stresses and must be carried out paying

attention not to damage the unit drain coupling.

• Foresee a siphon that, by eliminating the depression

caused by the fan, prevents suction of air from the drain

piping.

• The piping must have adequate slope to allow out flow.

• Anchor the piping with an adequate number of supports.

• On the contrary, cracking in the piping and air pockets

obstructing the outflow, are generated.

• Isolate piping and siphon to avoid condense dripping.

• Connect the condense drain to a rain drain network.

• DO NOT use white waters or sewage drains to avoid

possible inhaling of odours in case of evaporation of the

water contained in the si phon.

• At work end, check the regular outflow of the condense by

pouring water in the bowl.

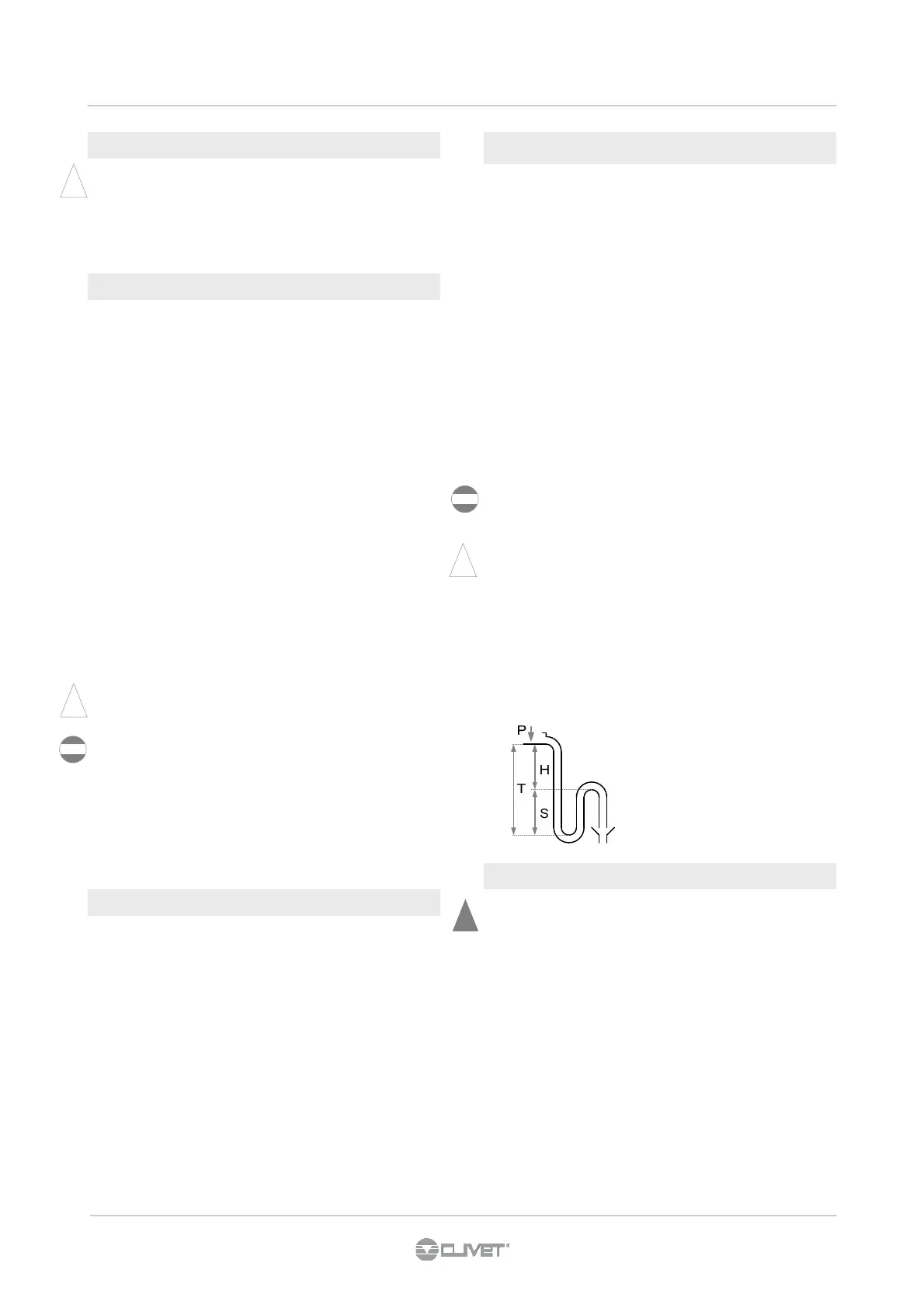

i

Example :

P = 300 Pa = 30 mm

T = 2P = 60 mm

S = T/2 = 30 mm

Siphon height calculation

T = 2P

S = T/2

P is the pressure determined by the fan in correspondence of

the condense collection bowl (approx. 1 mm = 9.81 Pa)

4.1 PRELIMINARY INFORMATION

Selection and installation of system components must be

carry out by installer.

Following a series of instructions that must be integrated with

what required by local regulations and by the code of practise.

INTERCEPTING VALVES

• Installed on the input and output, they allow to carry out all

the maintenance operations and possible without emptying

the installation.

THERMOMETERS AND PRESSURE GAUGES:

• Installed on the input and output of the main parts facilitate

the controls and the maintenance.

BLEED VALVES :

• Installed in all the highest points of the system, they allow

the venting from the circuit.

BLEEDING COCKS :

• Installed at the lowest points of the circuit, so as to allow

emptying .

EXPANSION TANK :

• It allows the system correct pressure to be maintained at

the water temperature changing. It has to be sized

according to the system water content.

WATER FILTER :

• If it is not built-in, it has to be immediately installed at the

unit water inlet, in a position easily accessible for cleaning.

• The filter should never be removed, the operation will void

the warranty.

SUPPORTS :

• for the weight of the water piping that must not rest on the

unit fittings.

FLOW SWITCH

• as a component of the system must always be provided.

4.2 COMPONENTS

4.3 OPERATION SEQUENCE

Before connecting the unit, carefully wash the system by filling

it and emptying it several times with clean water.

Ignoring this operation will lead to several filter cleaning

interventions and at worst cases can cause damages to the

exchangers and the other parts.

Execute leakage test before isolate the pipes.

To avoid heat dispersions and formation of condensate isolate

all the pipes.

Leave various point of service free (wells, vent-holes etc )

i

i

Adopt measures to prevent risk of freezing if the unit or

relative hydraulic connections can be subject to temperatures

near 0°C.

• isolate the piping

• protect the piping with heating cables laid underneath

the insulation

4.5 RISK OF FREEZING

!

Loading...

Loading...