35

Notions on refrigerant piping connection

m

CAUTION

Do not damage, tighten or deform the pipe

during cutting. This would greatly reduce the

heating efficiency of the unit.

6.1.3 Countersink the ends of the pipes

Correct flaring is essential to perfectly seal the gasket.

1 After removing burrs from the cut pipe, seal the ends

with PVC tape to prevent foreign materials from

entering.

2 Wrap the pipe in an insulating material.

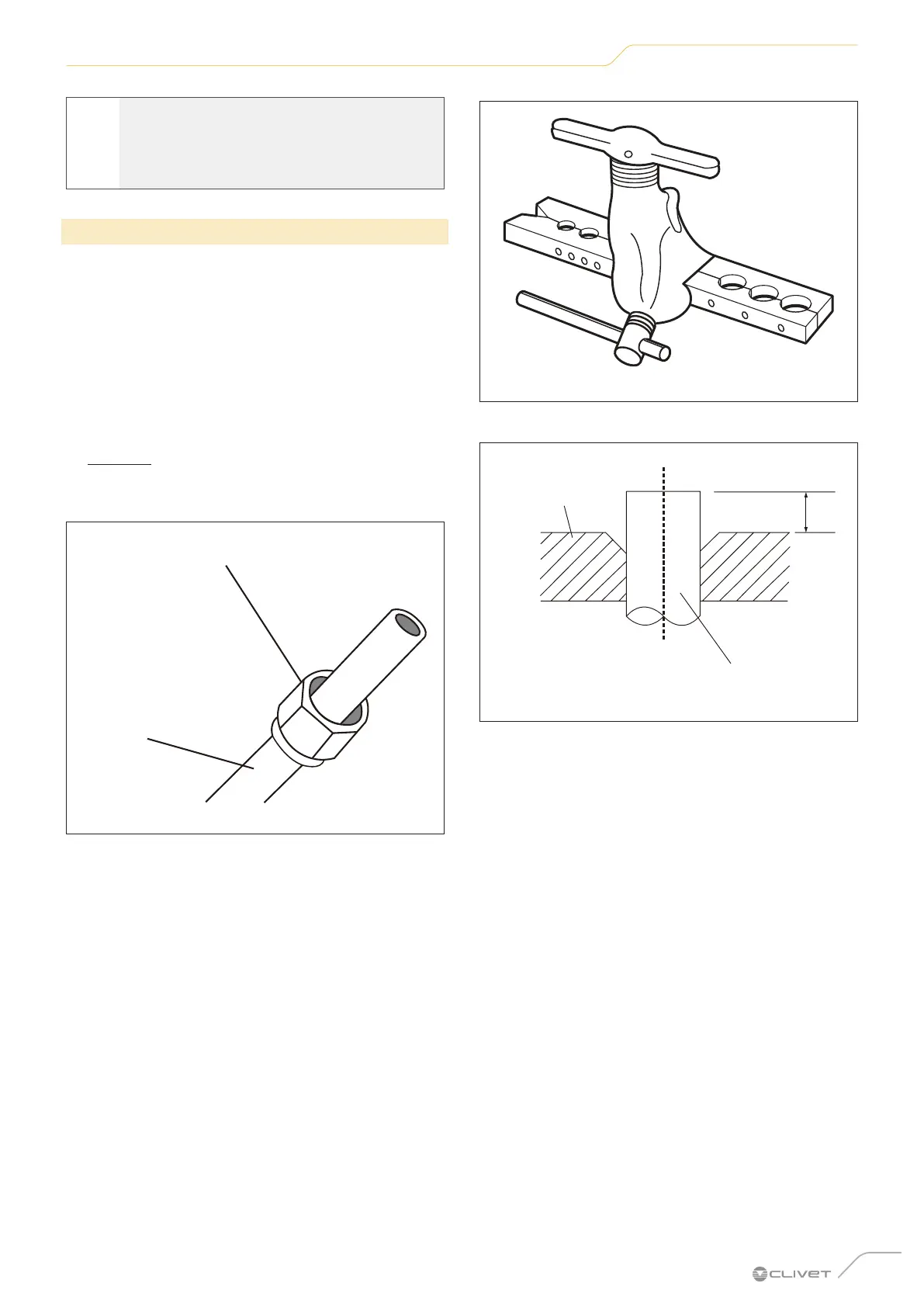

3 Place a countersunk nut at each end of the pipe. Make

sure that the nuts are facing in the correct direction,

because after countersinking it will no longer be

possible to apply them or change their direction (see

“Fig. 28”).

4 When you are ready to complete the flaring, remove

the PVC tape from the ends of the pipe.

Flared nut

Copper pipe

Fig. 28

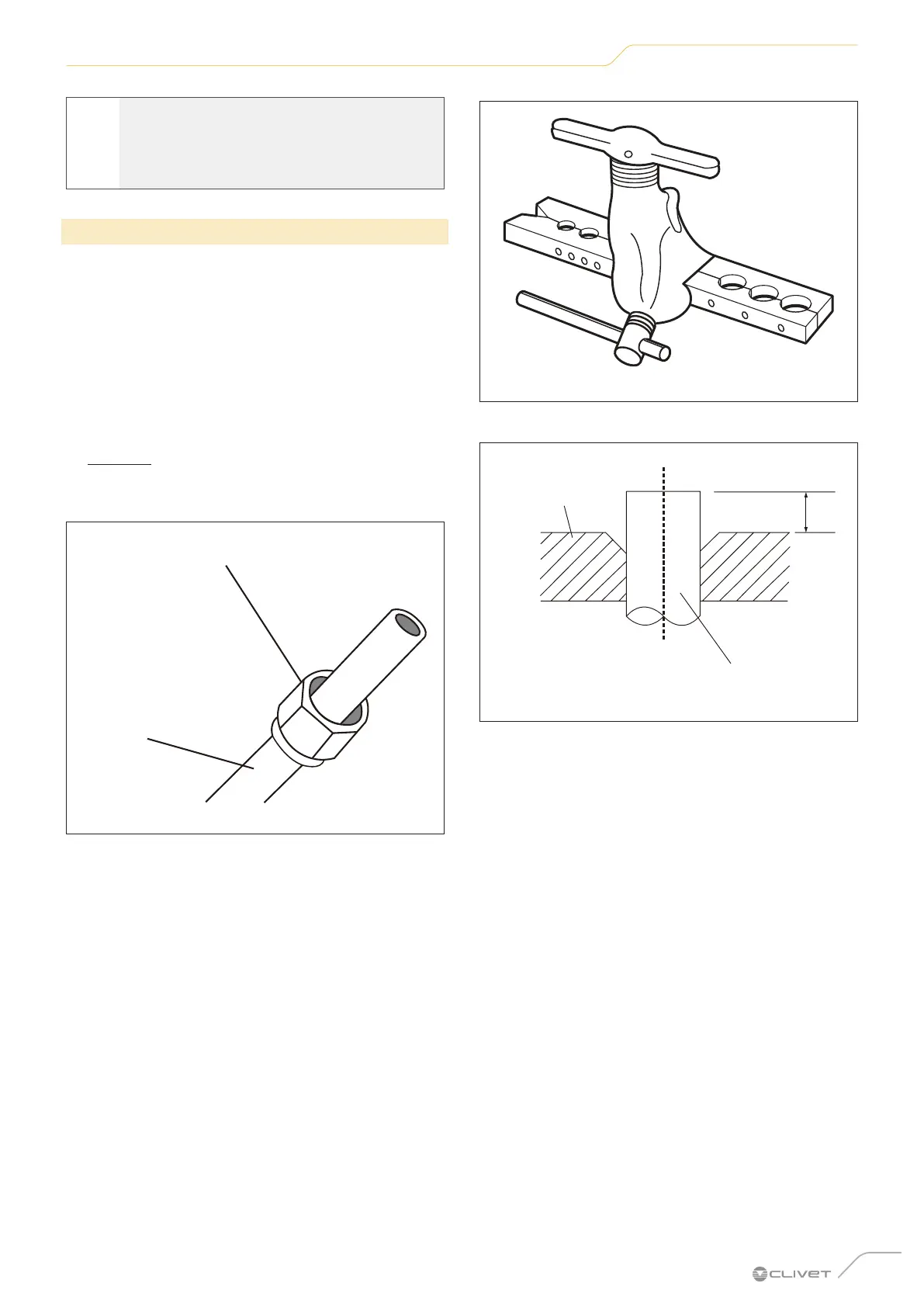

5 Tighten the end of the pipe into the template of

the flaring tool. The end of the pipe must extend

beyond the edge of the template, according to the

measurements indicated in the table below.

6 Apply the countersink screw to the template.

7 Turn the screw clockwise until the desired countersink

is achieved.

Fig. 29

Template

Pipe

A

Fig. 30

8 Remove the countersunk screw and template, then

check that the end of the pipe is countersunk evenly

and not cracked.

Loading...

Loading...