36

Notions on refrigerant piping connection

6.1.4 Connect the pipes

When connecting the refrigerant pipes, be careful not to

use excessive torque or perform other operations that

may damage them. First connect the low pressure pipe

and then the high pressure pipe.

l

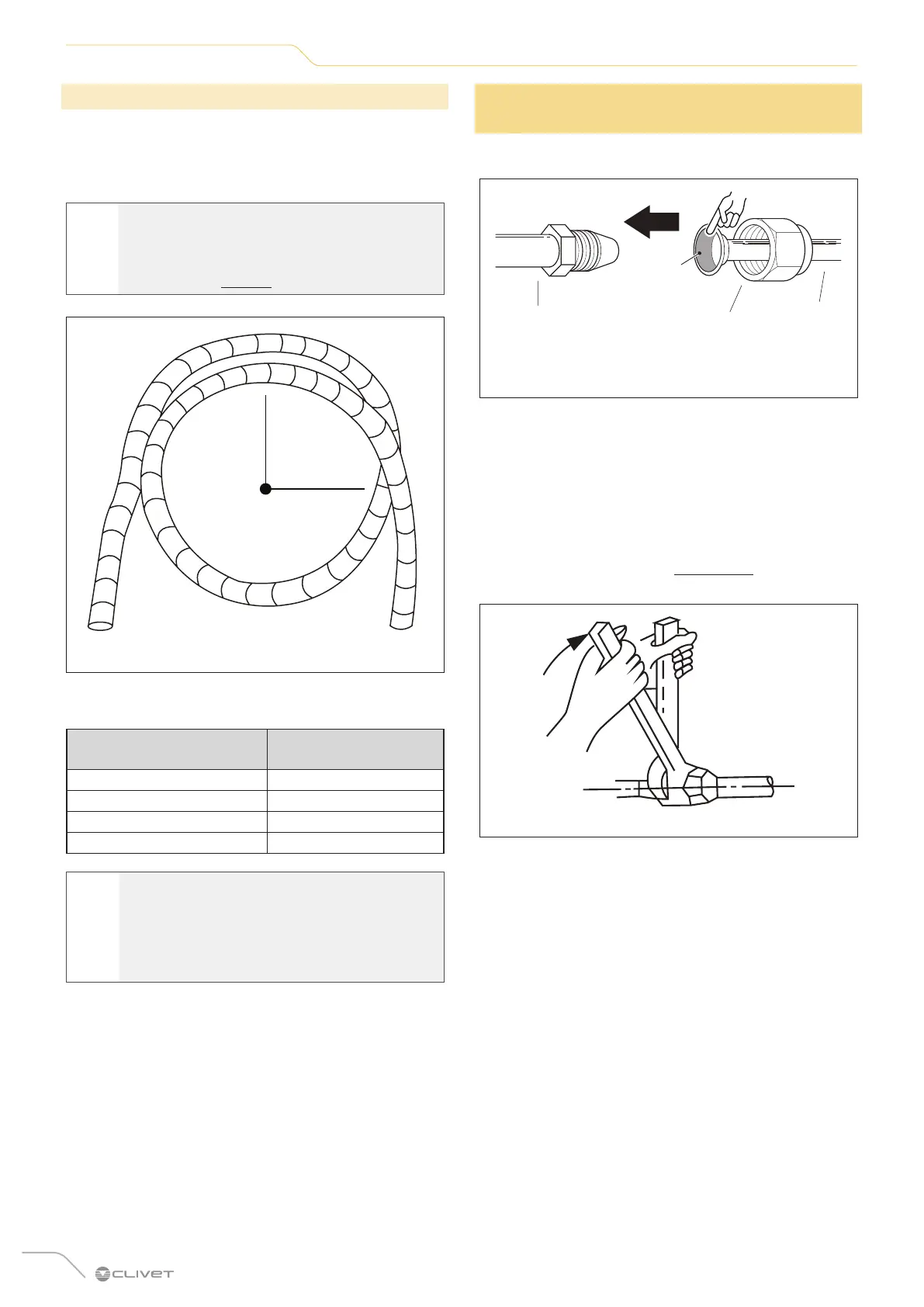

WARNING

When bending the connection pipes of the

refrigerant piping, observe a minimum radius

of 10 cm. See “Fig. 31”.

Radius > 10 cm

Fig. 31

TORQUES

Outer diameter of the pipe

(mm)

Tightening torque

(N•m)

Ø 6.35 (Ø 1/4") 14.2 - 17.2

Ø 9.52 (Ø 3/8") 32.7 - 39.9

Ø 12.7 (Ø 1/2") 49.5 - 60.3

Ø 15.9 (Ø 5/8") 61.8 - 75.4

m

CAUTION

DON'T USE EXCESSIVE TORQUE.

Excessive force can cause the nut to break or

damage the refrigerant piping. Do not exceed

the torque values shown in the table.

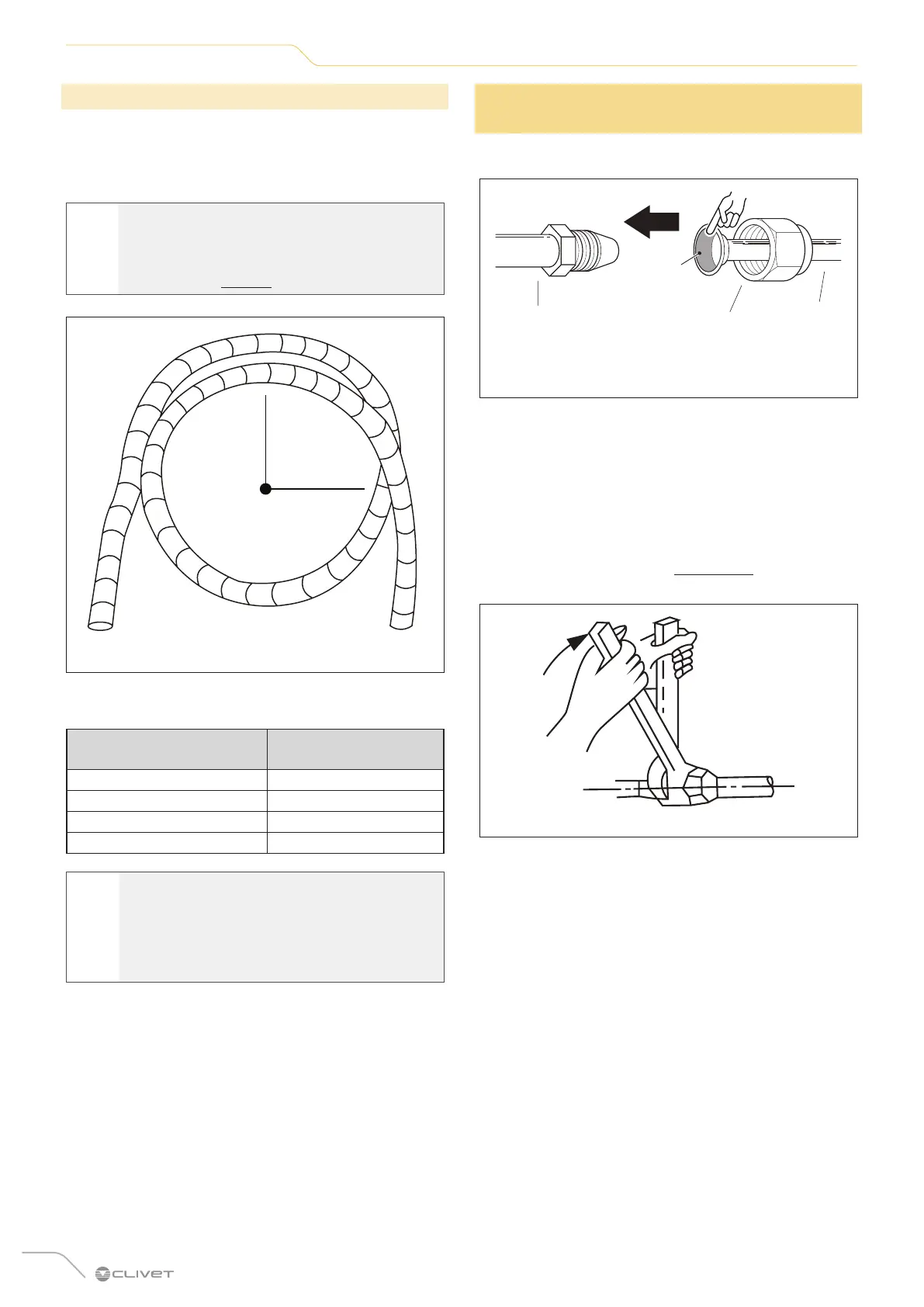

6.2 Connecting the pipes to the indoor

unit

1 Align the centre of the two pipes to be connected.

A

Indoor unit

piping

Flared nut Pipe

Fig. 32

2 Apply a little lubricating oil only to the inner surface of

the countersink (A).

3 Screw the flared nut by hand as far as possible.

4 Then fit the spanner round the nut.

5 Holding the nut firmly on the unit piping, use a torque

wrench to tighten the countersunk nut according to

the torque values in table “TORQUES”. Slightly loosen

the flared nut, then tighten it again.

Fig. 33

Loading...

Loading...