The mixing cycle consists of the following steps:

Closing of stuffing ejecting flap

Placing an empty stuffing trolley below the ejection flap,

Opening of tank cover,

Loading stuffing into the tank manually or with loading device,

Closing of tank cover,

Launching the mixing process.

Unloading of stuffing - after mixing, select convergent direction of paddles. Open the

flap of ejector with the lever (lock that is intended to prevent the accidental release of

the cover and opening flap should be released)

Next cycles are repeated as above.

ATTENTION!

Maximum level of mixed stuffing can not reach 100mm below the top edge of

tank border.

8. Cleaning and maintenance.

8.1. Lubrication

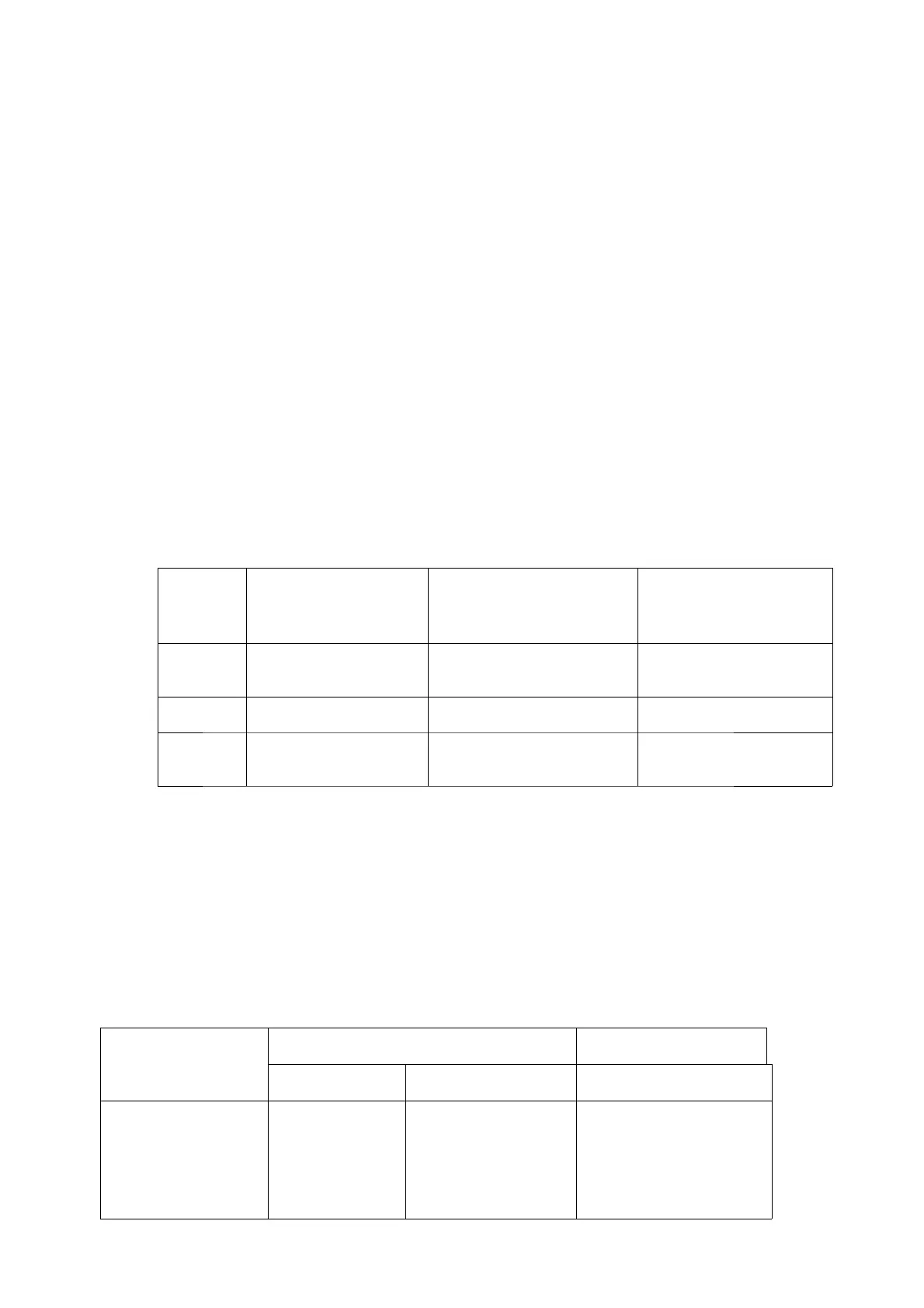

No.

Place of oiling Frequency Lubricant

2. 1

Gear motor

Replacement according to

manufacturer's instructions

Transmission oil

recomended by gear motor

producer

3.

Chain

Once every two weeks -

about 100 hours of action graphite grease

4.

Drive shaft bearings of

mixing paddles

Covered, do not require

lubrication, replace them

when clearances appear

Table no. 3.

8.2. Cleaning

ATTENTION!

Cleaning and washing the machine should be carried out by using cleaners for

stainless steel and in the way recommended by reputable manufacturers.

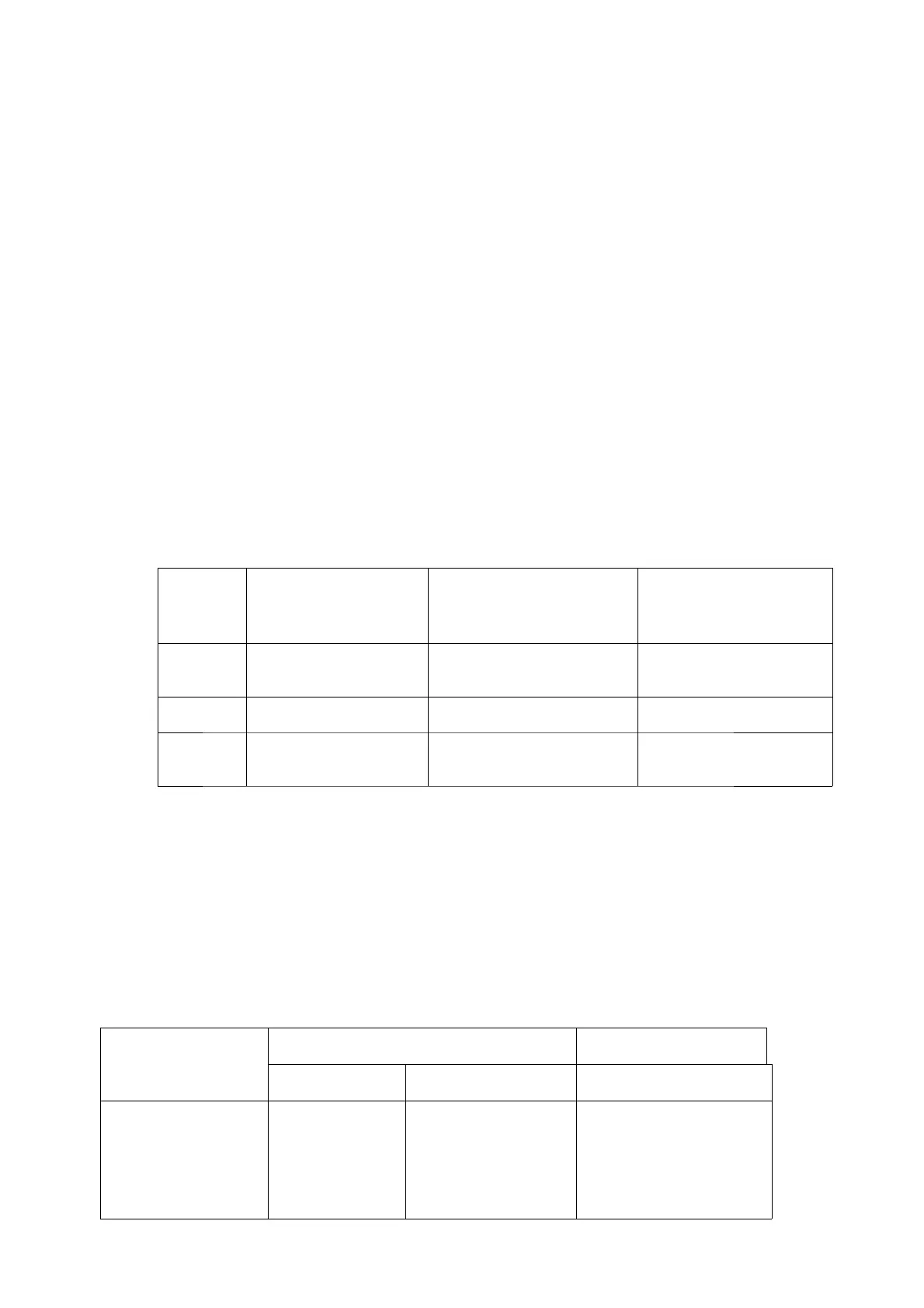

Recommended products and methods for cleaning, disinfecting and rinsing machines are

presented in Table 4 and 5.

Hygienic zone Cleaning Remarks

Frequency Method

Mixing shafts

Everyday, after

work

Cleaning the agitators

from the remnants of

meat and fat

embedded

Cleaning the agitators

with the tank cover open,

only with proper

operation of the proximity

switch and when the

power is turned off

8

Loading...

Loading...