16

Tips for use

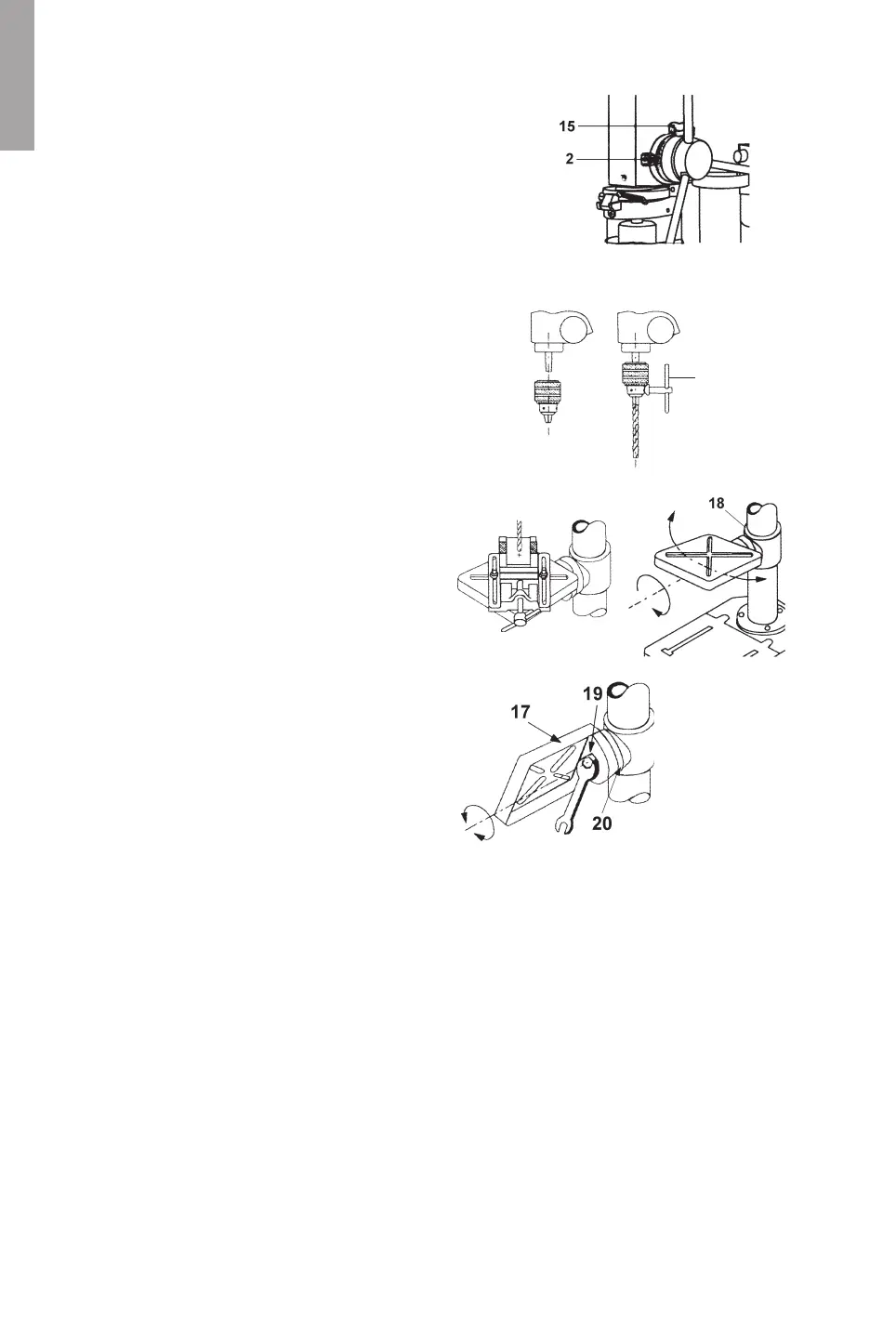

Depth stop

The machine is equipped with a depth stop

whichisadjustedusingthelever(15).The

drilling depth can be measured using the

scale on the depth stop (2).

Chuck

Drills and cylindrical shafted tools up to

16 mm in diameter can be fastened in the

chuck with the chuck key (16).

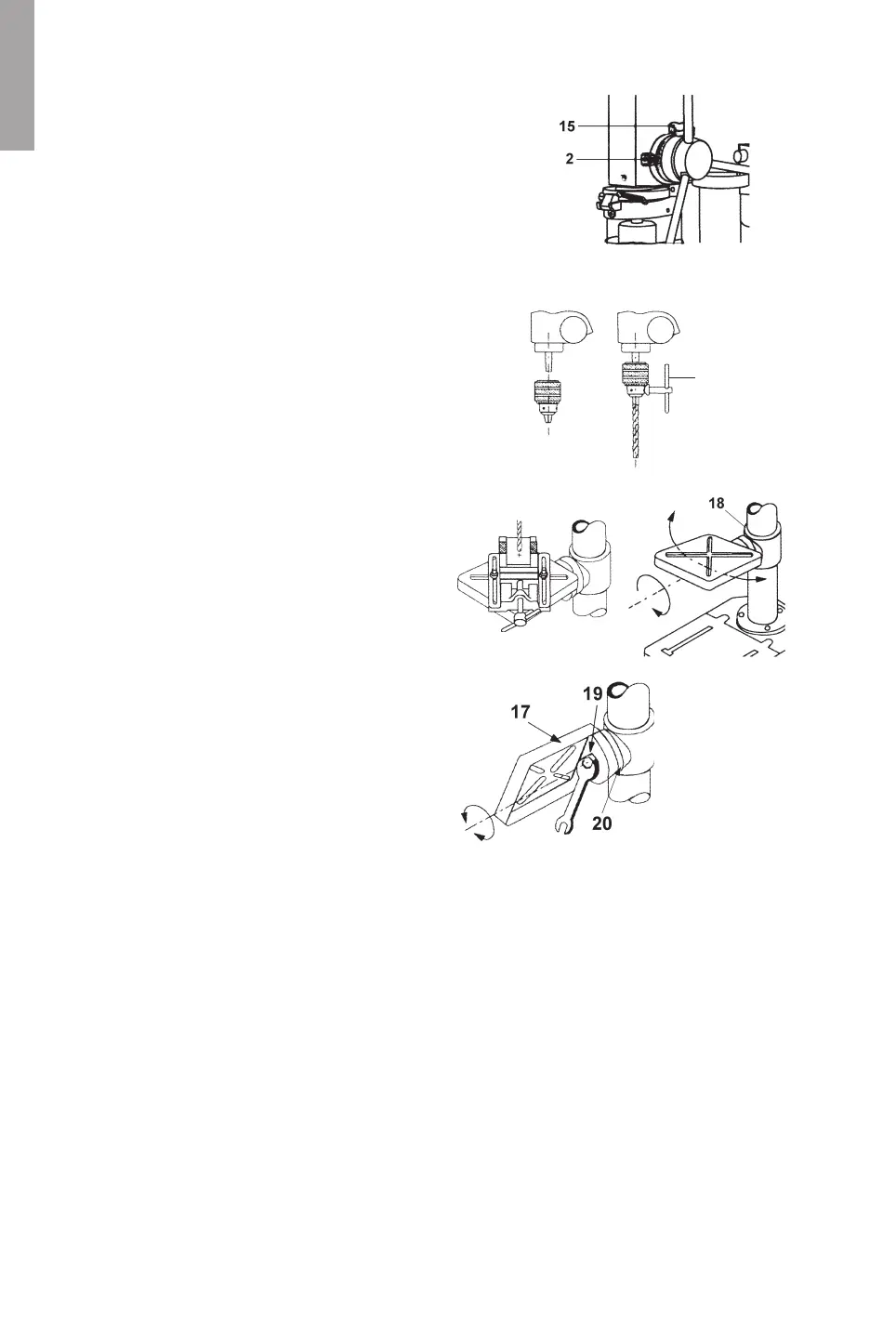

Fastening the workpiece

The table has slots for fastening T-bolts and

drill vices to it.

Adjusting the table

The table can be moved up and down the

pillar when the locking lever on the back of

the table support (18) isundone.Adjustthe

table so that there is enough room between

the drill and the table for the workpiece. The

table can also be moved to the side if you

wishtoxaworkpiecedirectlytothebase

of the drill.

Ifyouwishtodrillatanangle,thetablecan

be tilted and the workpiece clamped to the

table. Undo the bolt (19) on the hinge of

the table (20). Move the table (17) to the

desired position and then tighten the bolt

(19) again.

Rpm/min and rate of feed

The drill is fed using the three feed levers (5). The spindle speed is determined by the size of

drill bit and the type of material being drilled.

The rate of feed is a crucial factor for the life of the drill bit and quality of result.

Follow these basic rules:

- Thebiggerthediameterdrillbit,thelowerthespeed.

- If the material being drilled is hard there is a natural urge to apply more pressure to

thedrill,buttoavoidoverheatingthedrillbitonsuchoccasionsoneshouldapplyless

pressureandlowerthespeedofthespindle.Moreover,thedrillbitneedstobecooledwith

a suitable cooling solution depending on the type of material.

When drilling into thin material be careful not to apply too much pressure and feed too quickly.

Whendrillingdeepholes(twicethediameterofthedrillbit)itcanbedifculttogetridofthe

swarf,whichcanleadtothedrillbitbecominghot.Itisthereforeagoodideatoreducethe

feed rate and remove the swarf by lifting the drill out of the hole from time to time. When drill-

ingholeslargerthan8mmyoushouldrstdrillapilotholesothetipofthedrillbitisnotover-

loaded. In this way you stop the tip of the drill from being overloaded.

Loading...

Loading...