1930 SERVICE MANUAL

¥

specified value and that it is regulated correctly.

W e suggest that you and your service techni

cians review test procedures so that HV and HV

regulation are always checked as a standard

servicing procedure, and the reason for this pru

dent routine be clearly understood by everyone.

It is important to use an accurate and reliable

HV meter. It is recommended that the HV read

ing be recorded on each customers' invoice,

which will demonstrate a proper concern for the

customers' safety.

5. When troubleshooting and making test meas

urements in a receiver with a problem of ex

cessive high voltage, reduce the line voltage by

means of a Variac to bring the HV into accep

table limits while troubleshooting. Do not oper

ate the chassis longer than necessary to locate

the cause of the excessive HV.

6. New type picture tubes are specifically designed

to withstand higher operating voltages without

creating undesirable X-radiation. It is strongly

recommended that any shop test fixture which

is to be used with the new higher voltage

chassis be equipped with one of the new type

tubes designed for this service. Addition of a

permanently connected HV meter to the shop

test fixture is advisable. The CRT types used

in these new sets should never be replaced with

any other types, as this may result in excessive

X-radiation.

7. It is essential to use the specified picture tube

to avoid a possible X-radiation problem.

8. Most TV receivers contain some type of emer

gency “ Hold Dow n" circuit to prevent HV from

rising to excessive levels in the presence of a

failure mode. These various circuits should be

understood by all technicians servicing them,

especially since many hold down circuits are

inoperative as long as the receiver performs

normally.

Leakage Current Cold Check

1. Unplug the ac line cord and connect a jumper

between the tw o prongs of the plug.

2. Turn on the power switch.

3. Measure the resistance value between the

jumpered ac plug and all exposed cabinet parts

of the receiver, such as screw heads, antennas

and control shafts. When the exposed metallic

part has a return path to the chassis, the reading

should be between 1 megohm and 5.2 meg

ohms. When the exposed metal does not have

a return path to the chassis, the reading must

be infinity. Remove the jumper from the ac line

cord.

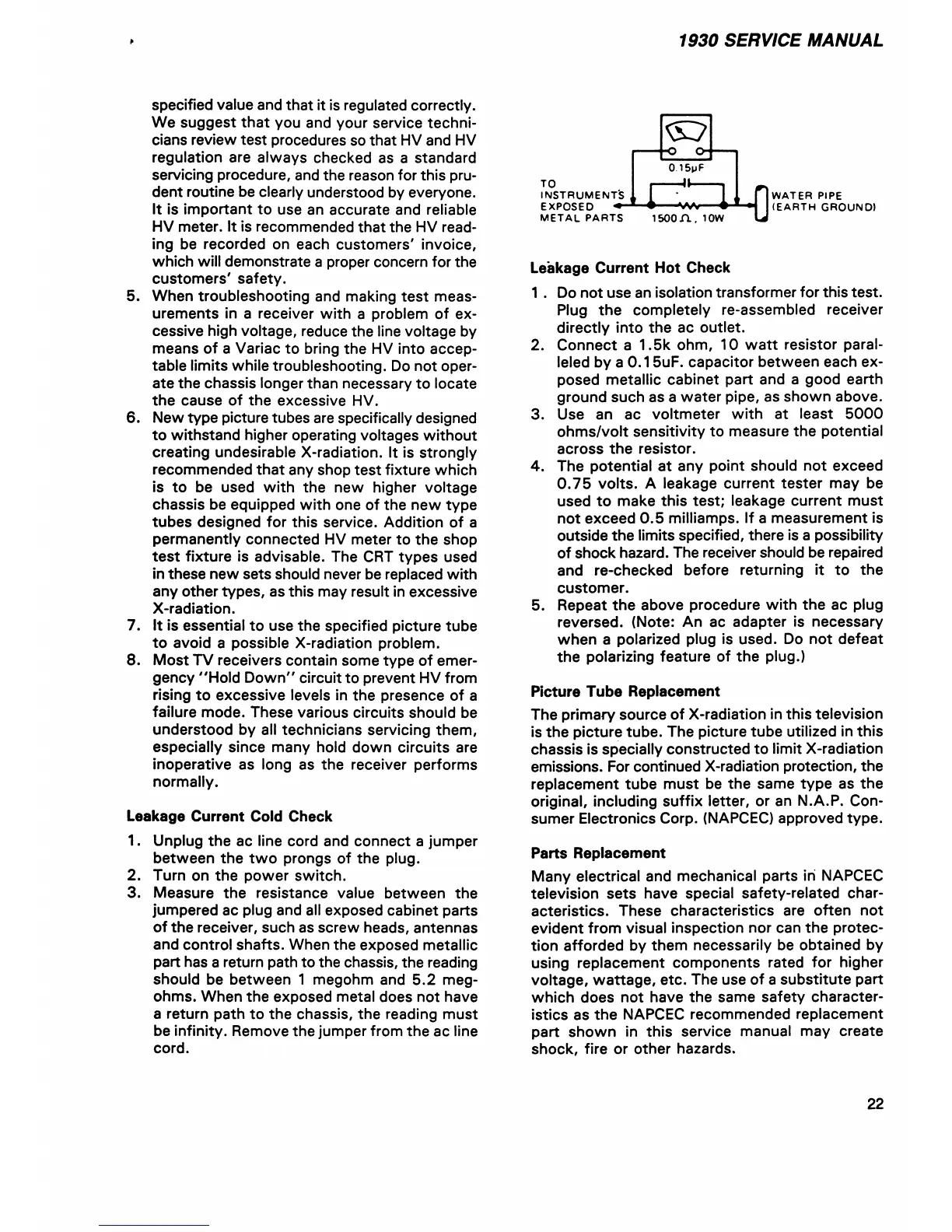

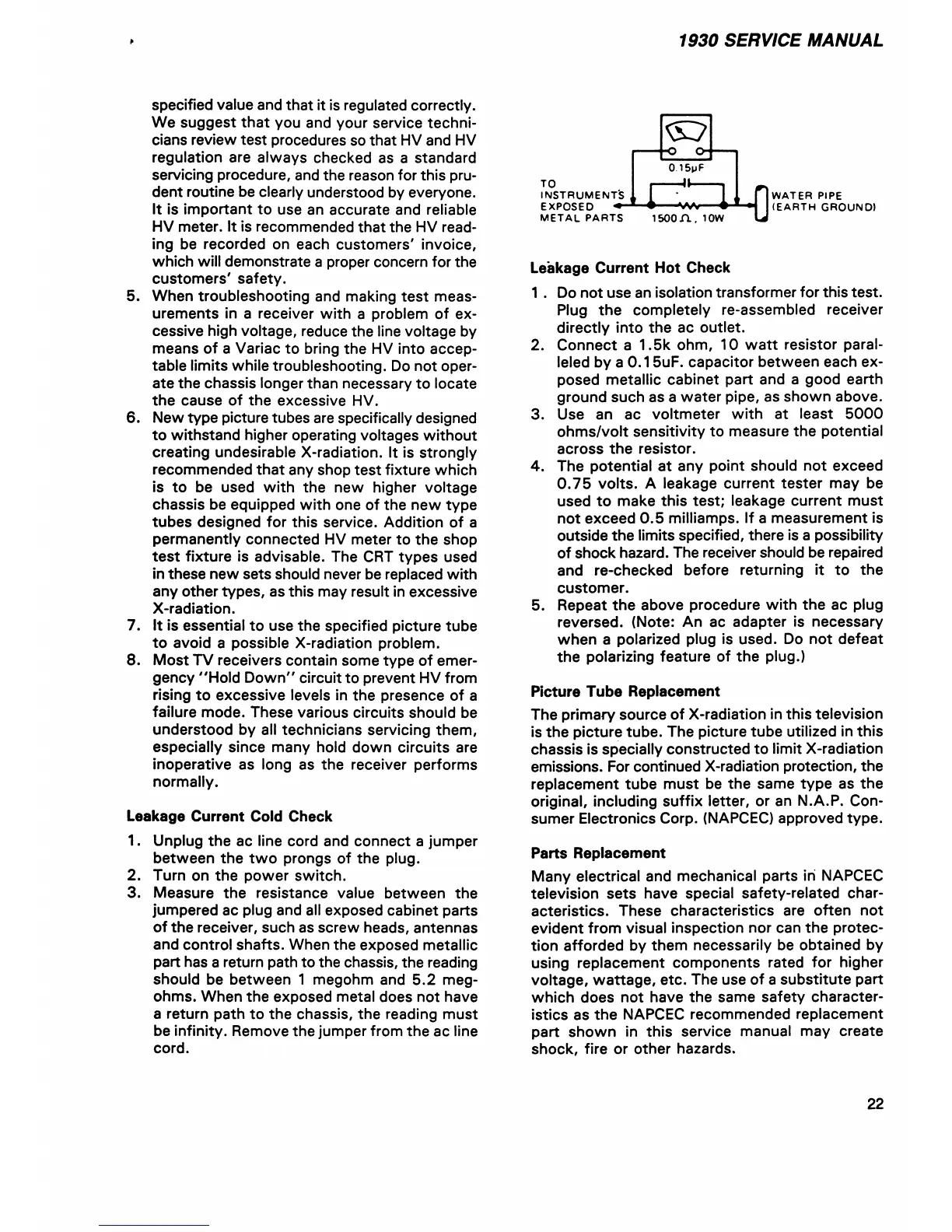

Leakage Current Hot Check

1 . Do not use an isolation transformer for this test.

Plug the completely re-assembled receiver

directly into the ac outlet.

2. Connect a 1.5k ohm, 10 w att resistor paral

leled by a 0 .1 5uF. capacitor between each ex

posed metallic cabinet part and a good earth

ground such as a water pipe, as shown above.

3. Use an ac voltmeter with at least 5000

ohms/volt sensitivity to measure the potential

across the resistor.

4. The potential at any point should not exceed

0.7 5 volts. A leakage current tester may be

used to make this test; leakage current must

not exceed 0 .5 milliamps. If a measurement is

outside the limits specified, there is a possibility

of shock hazard. The receiver should be repaired

and re-checked before returning it to the

customer.

5. Repeat the above procedure with the ac plug

reversed. (Note: An ac adapter is necessary

when a polarized plug is used. Do not defeat

the polarizing feature of the plug.)

Picture Tube Replacement

The primary source of X-radiation in this television

is the picture tube. The picture tube utilized in this

chassis is specially constructed to limit X-radiation

emissions. For continued X-radiation protection, the

replacement tube must be the same type as the

original, including suffix letter, or an N.A.P. Con

sumer Electronics Corp. (NAPCEC) approved type.

Parts Replacement

Many electrical and mechanical parts in NAPCEC

television sets have special safety-related char

acteristics. These characteristics are often not

evident from visual inspection nor can the protec

tion afforded by them necessarily be obtained by

using replacement components rated for higher

voltage, w attage, etc. The use of a substitute part

which does not have the same safety character

istics as the NAPCEC recommended replacement

part shown in this service manual may create

shock, fire or other hazards.

TO

INSTRUMENT'S

EXPOSED

METAt PARTS

isoon. iow

0

WATER PIPE

(EARTH GROUND)

22

Loading...

Loading...