93

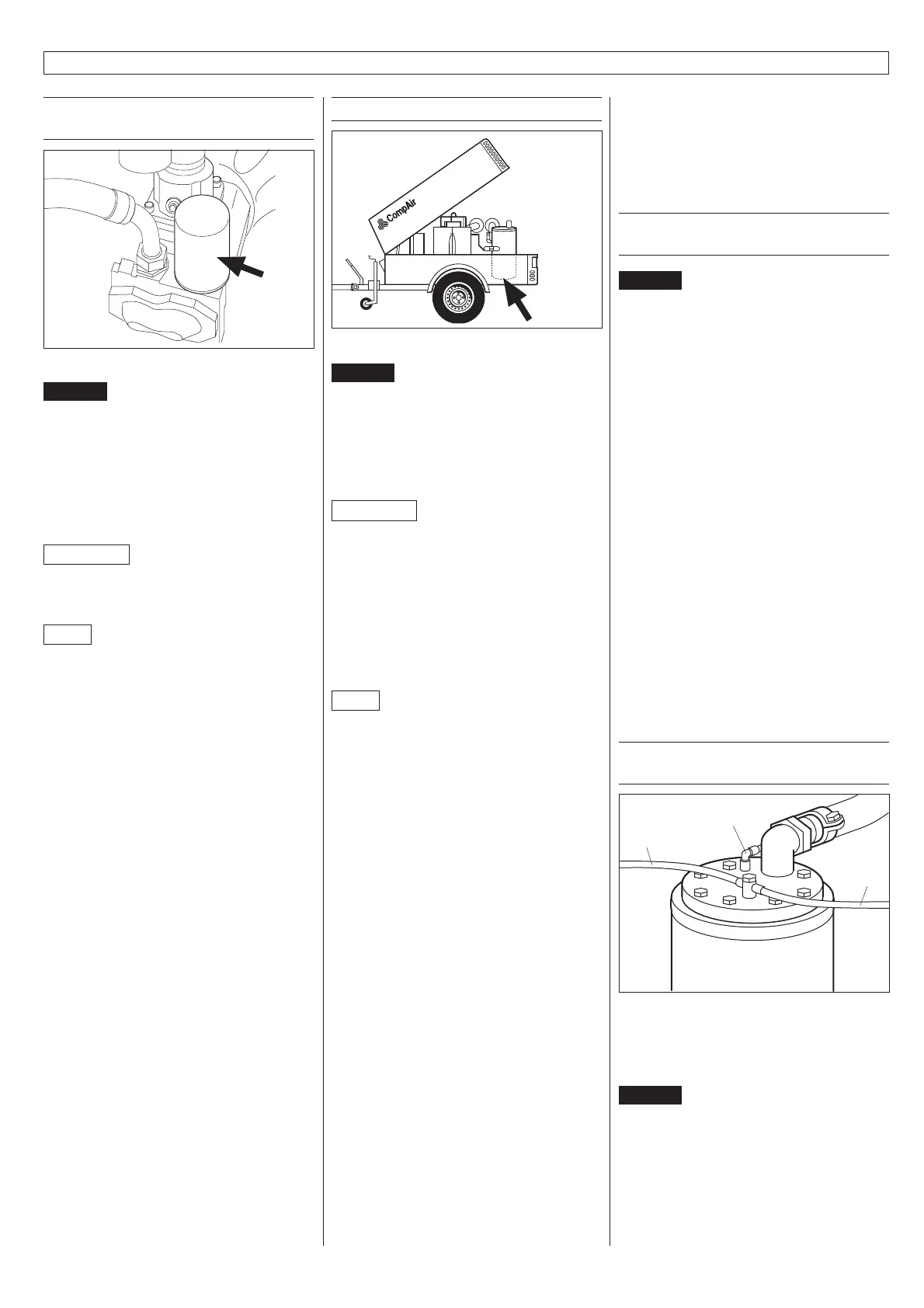

9.4.1 Oil filter replacement

(compressor)

Fig. 26

Danger

Only replace the oil filter cartridge when

the engine is at a standstill and the

screw compressor is not under

pressure.

Caution with hot oil: risk of scalding!

Spill no oil!

Attention

Change the oil filter every 1,000 oper-

ating hours, but at least once per year.

Note

Dispose of oil filter cartridge in accordance

with the relevant regulations - hazardous

waste!

Check for leaks.

Changing the oil filter:

* Unscrew the oil filter cartridge using

appropriate tools

* Dispose of oil filter cartridge

* Apply a thin coat of oil to the seal of the

new oil filter cartridge

* Screw on and tighten the new oil filter

cartridge (Ident-No. 048 199 74) (follow

the instructions on the oil filter cartridge)

* Check for leaks

* Check oil level, add oil if necessary

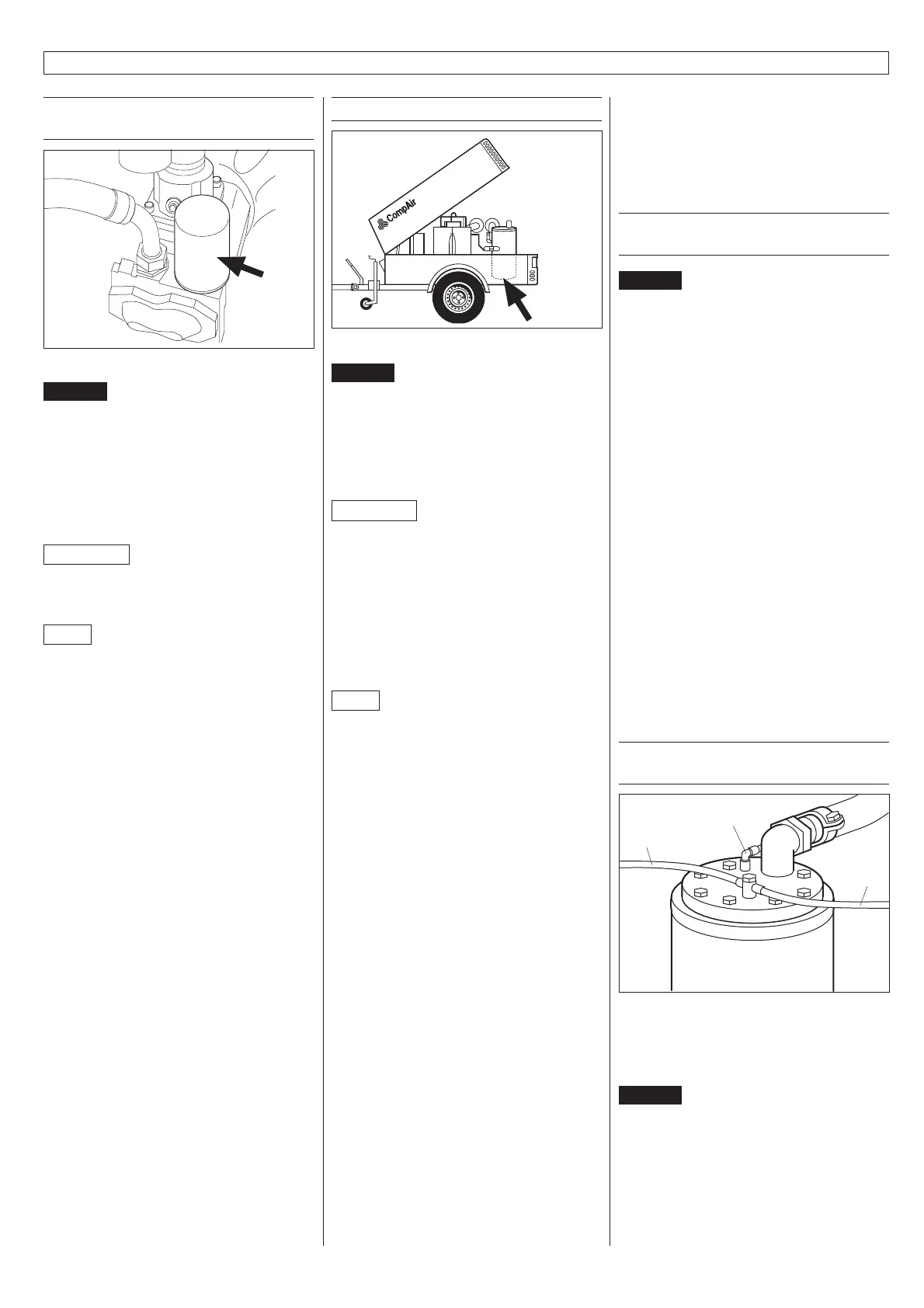

9.4.2 Oil change (compressor)

Fig. 27

Danger

Only change the oil when the engine is

at a standstill and the screw

compressor is not under pressure.

Caution when draining off hot oil:

risk of scalding! Spill no oil!

Attention

Change the oil filter every 1,000 oper-

ating hours, but at least once per year.

The screw compressor must not be

under pressure during oil change.

Drain the oil at operating temperature.

Do not mix oils of different

specifications.

Note

Collect used oil, do not allow it to enter the

soil. Dispose of oil in accordance with the

relevant regulations - hazardous waste!

Spill no oil!

Check for leaks.

Changing the oil:

* Unscrew dipstick

* Place oil drain pan under oil drain valve

* Unscrew the sealing cap of the pressure

vessel

* Collect used oil in the oil drain pan

* When the used oil has been drained

completely, use a new sealing ring on

the sealing screw of the pressure

vessel, position and tighten screw or

close the oil drain valve

* Fill up with new oil (see section

"Specifications" in chapter 1 for initial

oil capacity; use a little less oil when

performing an oil change).

* For lubricants see “Lubricant Table”

* Check sealing ring on dipstick, replace if

necessary

* Screw in and tighten dipstick

* Start screw compressor, run for approx.

two minutes, check for leaks

* Switch off screw compressor

* Check oil level, add oil if necessary

9.4.3 Checking the automatic

monitoring system

Danger

Caution! High voltage! The sensors of

the automatic monitoring system must

not be short circuited.

Check individually every 1000 operating

hours:

1. Temperature sensor - screw compressor

(pressure connection)

2. Oil pressure switch - engine

3. Oil temperature gauge - engine

Checking the automatic monitoring system:

* Disconnect connecting cable

* Connect to ground at oil temperature

gauge.

* Start screw compressor

* The automatic monitoring system must

switch off the screw compressor

immediately after starting, and the

“Fault” indicator lamp must come on.

9.4.4 Inspecting / Replacing the fine

separator

Fig. 28

1 Connection for P controller

2 Connection for compressor suction line

3 Oiler connection

Danger

Pressure tank is under pressure. Only

work when the motor is at a standstill

and the screw compressor is not under

pressure.

Caution with hot oil: risk of scalding!

Spill no oil!

9. Maintenance

1

2

3

Loading...

Loading...