94

Note

Dispose of fine separator in accordance

with the relevant regulations - hazardous

waste!

Check for leaks.

Replace the fine separator at least once

per year or measure the differential

pressure as follows:

* When the engine is at a standstill and

the screw compressor is not under

pressure, unscrew the dipstick from the

pressure tank.

* Screw in the reducing adapter.

* Screw the pressure gauge into the

reducing adapter.

* Start the screw compressor.

* The difference in pressure between the

pressure gauge on the pressure tank

and the pressure gauge on the

instrument panel must not exceed 1 bar.

If the differential pressure is > 1 bar, the

fine separator cartridge must be replaced.

* Remove all hexagon screws around the

circumference of the lid.

* Remove the lid and the old fine

separator.

* Remove the old seals from the pressure

vessel, clean the sealing surface and fit

a new seal (part no. 931 820 00).

* Insert a new fine separator (part no.

131 382 74) into the pressure vessel

and fit a new seal (part no. 931 820 00).

* Fit the lid. Insert the hexagon screws

and tighten them across the diagonal

(tightening torque see Chapter 9.4.9

"Torque specifications").

* Check for leakage.

* Dispose of the old fine separator

cartridge in the specified manner.

9.4.5 Air filter replacement

(compressor / engine)

Danger

All inspections and servicing work must

be carried out when the engine is at a

standstill and the screw compressor is

not under pressure.

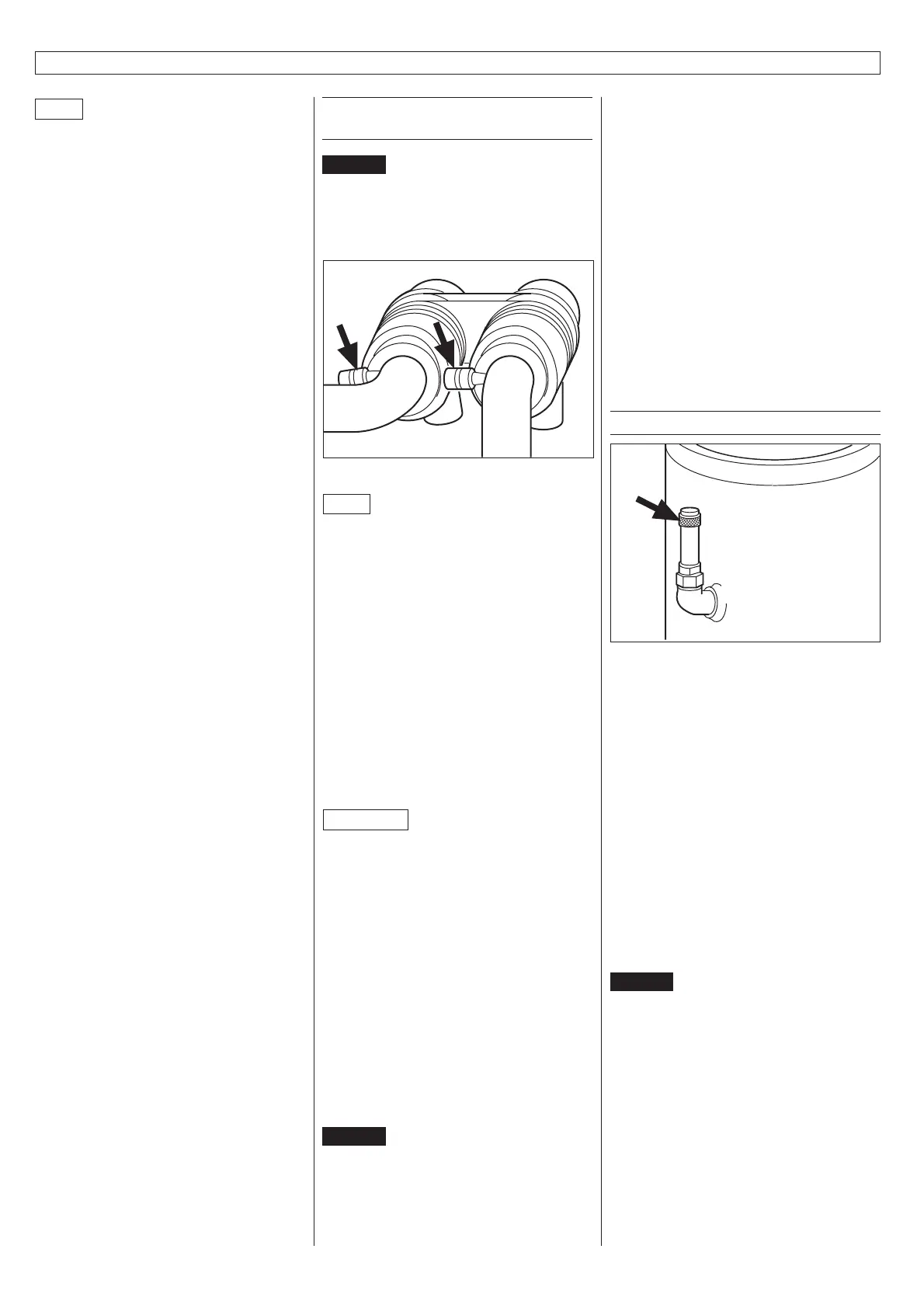

Fig. 29

Note

Check the air filter every week for dust.

Every air filter is supplied with a

maintenance indicator, which indicates

the adding of the filter cartridge. The

maintenance intervals of the air filter

depend on the air pollution.

If the red field of the maintenance indicator

is visible and stays engaged when the

screw compressor is turned off, you must

exchange the air filter cartridge (at least

every 12 months).

Replace the air filters of the screw

compressor and of the engine once yearly.

Do not clean or reuse the air filter.

Attention

Replace the safety cartridge (optional)

at the latest every third time the air filter

element is replaced.

Replace air filter.

* Loosen the tensioning brackets at the air

filter and fold away.

* Remove filter hood.

* Remove filter cartridge from the filter

hood.

* Remove safety cartridge (optional)

from the housing.

* Replace filter cartridge.

Danger

Never clean the air filter cartridge with

inflammable liquids.

9. Maintenance

Reassembling the air filter:

* Clean the sealing surface in the filter

housing.

* Insert safety cartridge (optional) and

ensure correct seating.

* Insert the filter cartridge and make sure

that the seal is properly seated.

* Replace filter hood and fasten using the

tensioning brackets (the tensioning

brackets can only be closed if the filter

cartridge with seal is seated properly on

the sealing surface of the filter housing).

* Reset the maintenance indicator by

pressing the reset lever.

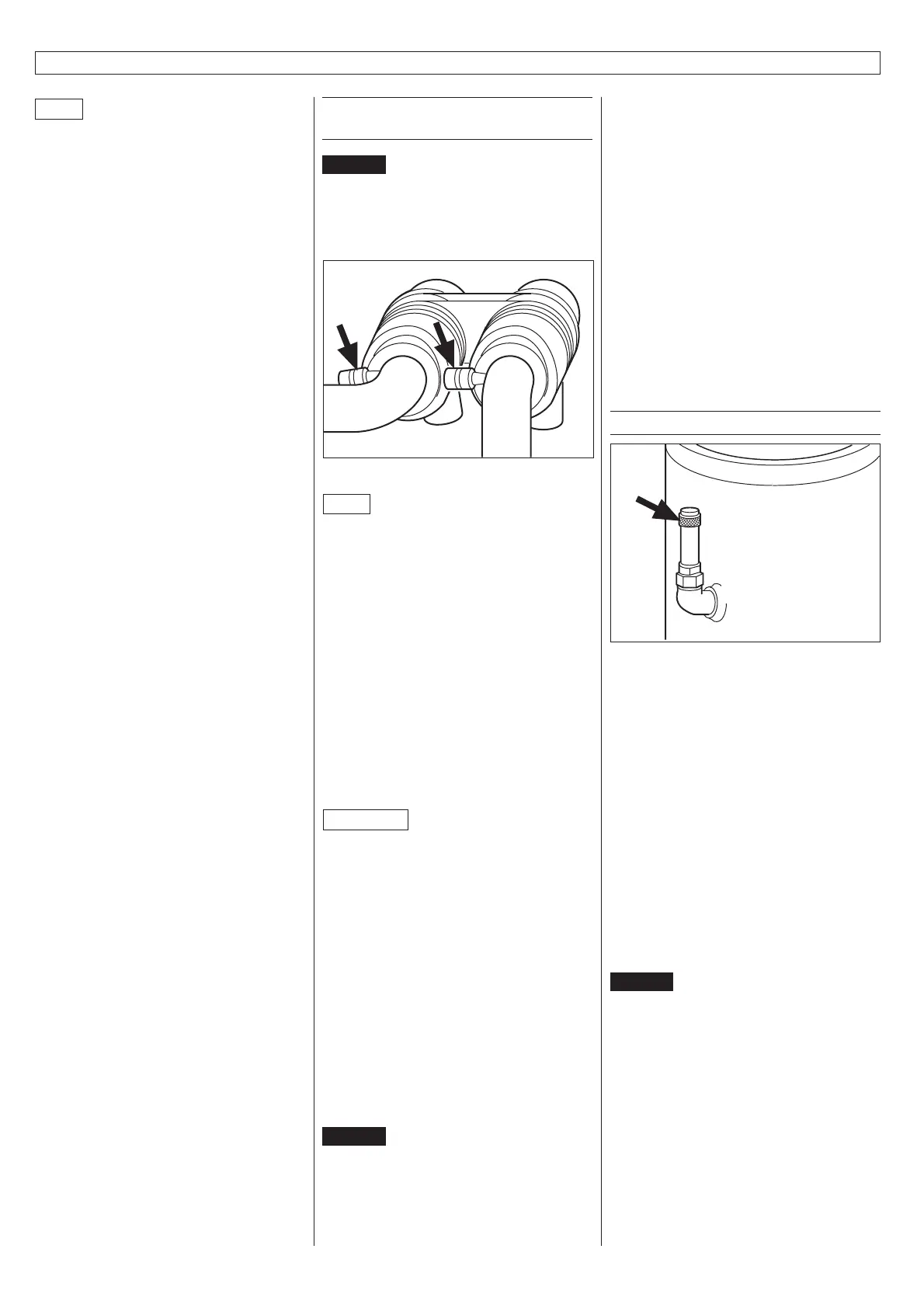

9.4.6 Checking the safety valve

Fig. 30

Check the operation of the safety valve at

least twice a year. The check is carried out

with the system pressurised. Carefully turn

the knob anti-clockwise, until the internal

pressure lifts the valve cone, releasing a

mixture of oil and air. Then turn the knob

fully clockwise again.

In accordance with national standards,

but at least once a year, carry out a

suitable test to check whether the valve

blows down at the correct pressure.

If the valve is not working properly,

replace it immediately with a new one

designed for the system. This type of

operation may only be carried out by

trained personnel.

Danger

The screw compressor must not be

operated with a faulty safety valve!

A mixture of oil and air will escape when

the valve is checked/tested.

Loading...

Loading...