CompAir Limited

page 38

z Refer to the safety procedures before carrying

out any fault finding investigation on the

compressor unit.

WARNING

z Lethal voltages are used in this equipment.

Use extreme caution when carrying out

electrical checks. Isolate the power supply

before starting any maintenance work.

FAULT FINDING

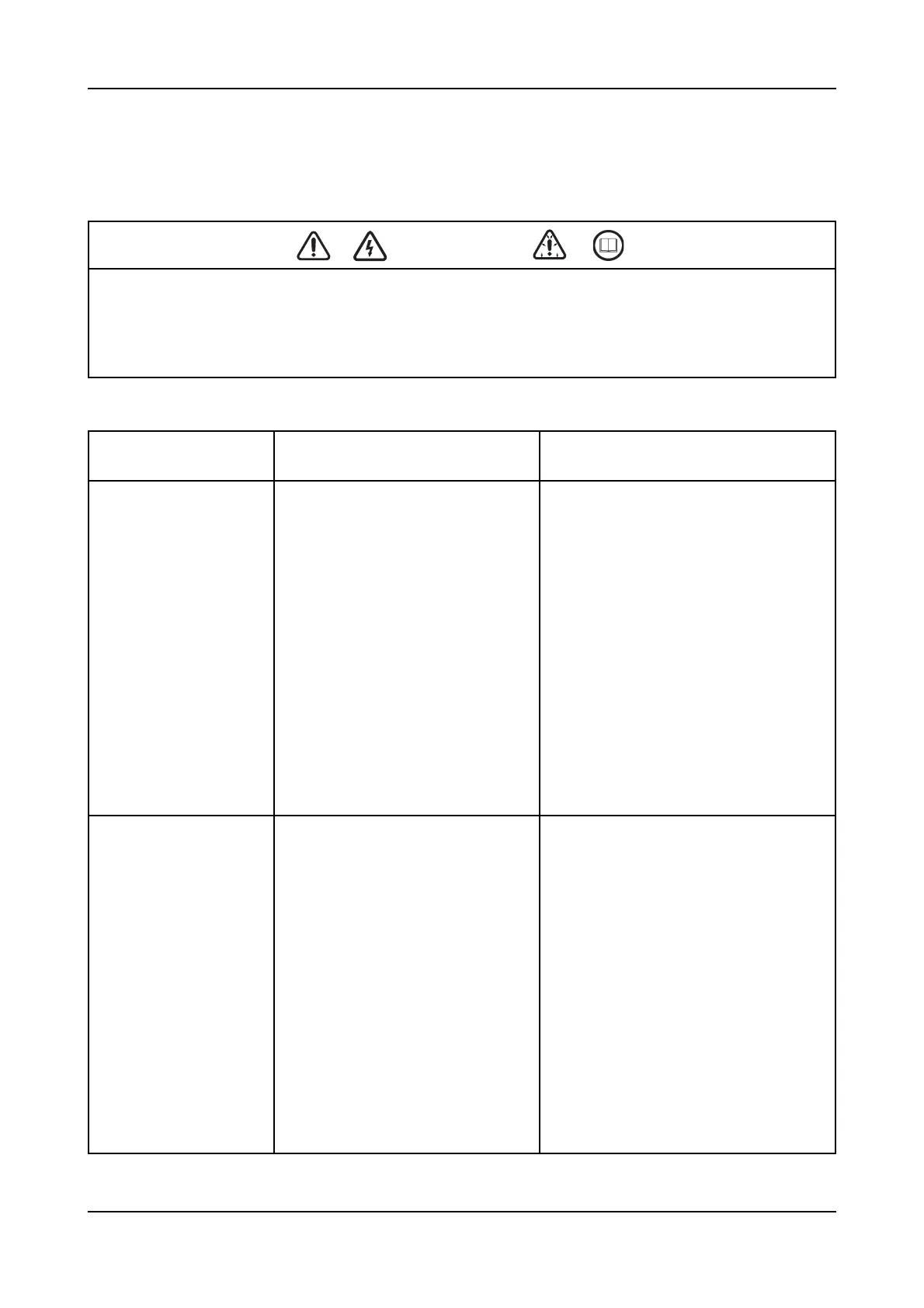

Indication Possible Cause Remedy

Low oil pressure. (1) Low oil level. (1) Check/top up oil.

(2) Incorrect grade of oil in (2) Drain crankcase and refill with

crankcase. correct oil.

(3) Oil pump drive belt or pulley (3) Check drive belt and pulley.

loose. Rectify or renew as necessary.

(4) Oil pressure gauge faulty. (4) Check gauge calibration.

Renew gauge if defective.

(5) Incorrect setting of oil (5) Check setting of valve. If

pressure relief valve. necessary remove and clean

Ball valve sticking in valve assembly.

open position. Check seating. Reset valve.

(6) Clogged oil filter element. (6) Renew oil filter element.

(7) Broken or loose connections (7) Check condition of oil pipes

on oil pipework. and filter. Renew if necessary.

(8) Oil pump gears faulty. (8) Renew oil pump gears.

(9) Worn main bearings. (9) Inspect bearings and small

end bushes. Renew if necessary.

Compressor (1) Inadequate ventilation of (1) Check ventilation meets

overheating. compressor room. the recommendations in the

'Installation' section of this

manual.

(2) Incorrect positioning of (2) Check positioning meets

compressor or aftercooler. the recommendations in the

'Installation' section of this

manual.

(3) Valves faulty. (3) Remove valves. Inspect valve

plates, springs and seats.

Check condition of ring joints.

Renew as necessary .

(4) Intercooler passages (4) Clean intercooler internally and

obstructed (usually only externally.

after very long service).

Loading...

Loading...