12

COMUNELLO ®Copyright 2013 - All right reserved

4 INSTALLATION

4.1 PRELIMINARY CHECKS

Before starting the installation work, check the condition of the product

components, the suitability of the chosen gate opener model and the

suitabilityoftheintendedinstallationenvironment:

• Ensurethatallmaterialusedisinperfectconditionandtforpurpose.

• Makesure that the mechanical structure of the gate is suitable for

automation. This product cannot be used to automate a gate unless

the gate is already in good working order and safe; furthermore, it

cannot remedy defects caused by incorrect installation or lack of

maintenanceofthegate.

• Checkthattheoperatingconditionsofthedevicesarecompatiblewith

the stated operating limits.

• Movethegateleavesmanuallyinbothdirectionstoensuretheforce

requiredisconstantthroughoutthefullrangeofmovement.

• Movethe gate leavesmanually to anyposition then release them to

checkthattheyremainstationary.

• Checkthattheareainwhichtheoperatoristobemountediscompatible

withthesizeoftheunitandmakesurethereissufcientclearancefor

thefullmovementofthearm.

• Ensurethatthereissufcientspacearoundtheoperatortoperformthe

manual release procedure.

• Ensurethatthesurfacesonwhichthedevicesaretobemountedare

solid and able to provide a secure anchorage.

• Ensurethatalldevicestobeinstalledareinaprotectedlocationsuch

thatminimizestheriskofaccidentalimpact.

4.2 OPERATING LIMITS

Beforestartingtheinstallationworkmakesuretheoperatoriscorrectlysized

inrelationtothedimensionsandlengthofthegateleavesandwithinthe

limitsofthevaluesgiveninthechapter“Producttechnicalspecications”.

4.3 PREPARATORY WORK FOR INSTALLATION

WithreferencetoFIG.1AeaFIG.1B,choosetheapproximateposition

inwhicheachcomponentofthesystemistobeinstalledandchoosethe

mostappropriateconnectionlayout.Listofcomponentsrequired:

• Electromechanicaloperators.

• Pairofphotocells.

• Pairofopeninglimitstopsandclosingstop.

• Postsforphotocells.

• Flashinglight.

• Keyselectorswitchordigitalkeypad.

• Verticalelectriclock(recommendedforgateleavesofmorethan3m).

• Controlunit.

4.4 INSTALLING THE RAM OPERATOR

4.4.1 INSTALLATION

Performthemanualreleaseasdescribedinheading4.4.3

• Choose the position for the gate opener in correspondence with a

sturdy cross member on the gate.

• Temporarilysecuretherearplatetothepillar,whichmustbeatleast100

mminwidth(FIG.2).

• Withthegatefullyclosed,xthefrontplatetothegateleaf(FIG.3).

• Coupletheoperatortotherearbracketusingthesuppliednutandbolt

(FIG.4).Theoperatorcannotbeinstalledwiththecoverupward.

• Fixtherodtothefrontplatewiththesuppliednutandbolt(FIG.4).

4.4.2INSTALLATIONOFLIMITSTOPSANDSWITCHES

TheRAMoperatorisnotequippedwithelectroniclimitswitchesanditis

thereforeessentialtoensurethatthegatetobeautomatedisequippedwith

mechanical opening and closing limit stops.

4.4.3OPERATORMANUALRELEASE

Perform the manual release procedure when the gate is to be opened

manually. Activation of the release system may result in uncontrolled

movementsofthegateinthepresenceofimbalanceormechanicalfaults.

Toreleasetheoperator,proceedasfollows:

• Opentheplastichatchandinsertthereleasehandle(FIG.5).

• Turnthehandleclockwise(FIG.6).

• Thisactionservestodisengagethegeartherebyallowingthegatetobe

openedmanually(FIG.7).

• To resume automatic control of the gate, return the key to its initial

position(FIG.8)

• Removethereleasehandleandstowitinasafeplace(FIG.9).

5 PREPARATION FOR ELECTRICAL

CONNECTIONS

• Performthemanualreleaseasillustratedinheading4.4.3.

• RemovetheplasticcoverasshowninFIG.10.

• Loosencablegland“G”locatedonthelowersideoftheoperatorFIG.10.

• InsertthepowercableFIG.11.

• Connectthewirestotheterminalboardasshownontheadjacentlabel.

• Connecttheearthwiretotheterminaleyenexttotheterminalboard

FIG. 11.

• Securethecablebytighteningthecablegland.

6 TESTING

Each part of the automation system, e.g. safety edges, photocells,

emergency stop, etc. must be tested; follow the procedures shown in

theinstructionmanualssuppliedwiththedevicesinquestion.Performthe

followingsequenceofoperationsfortestingofRAM:

• Checkthatalltheprescriptionsinthismanualhavebeenfollowedscrupulously,

withspecialattentiontothematterssetdowninchapter1“Prescriptions”.

• Using the supplied control or stopping devices (key selector switch,

controlbuttonsorradiotrasmitters),performgateopening,closingand

stoppingtestsandmakesurethegaterespondscorrectlytothevarious

commands.

• Checkoperationofallthesystem’ssafetydevices(photocells,safety

edges,emergencystop,etc.)onebyone.

• Ifpotentiallyhazardoussituationscausedbymovementofthegateleaf

havebeeneliminatedbylimitationofimpactforce,theassociatedforce

must be measured as prescribed in standard EN 12445.

7 PRODUCT MAINTENANCE

Maintenancemustbecarriedoutatregularintervalsbyqualiedpersonnel

incompliancewiththeprovisionsofstatutorylegislationandtheregulations

in force. RAM must be serviced at least once every 6 months or after

10.000 operating cycles since the last service.

• Disconnecttheoperatorfromallpowersupplies

• Checkallthemovingpartsandreplaceanywornparts.

• Checkallpartsoftheautomationsystemforsignsofdeterioration.

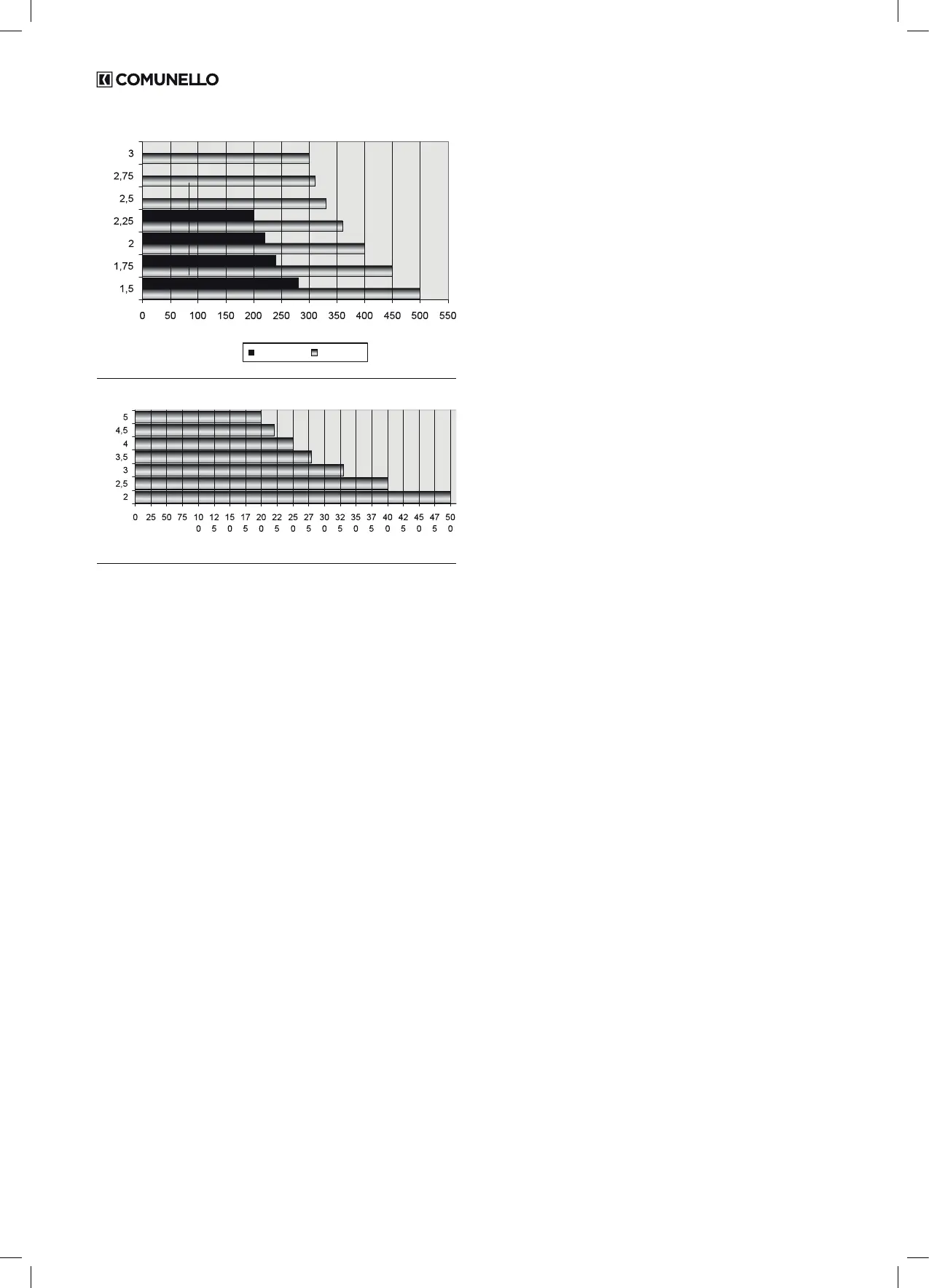

RAM 300RAM 220

LEAF WEIGHT (Kg)

LEAF LENGHT (m)

LIMITS OF USE - RAM 220 - RAM 300

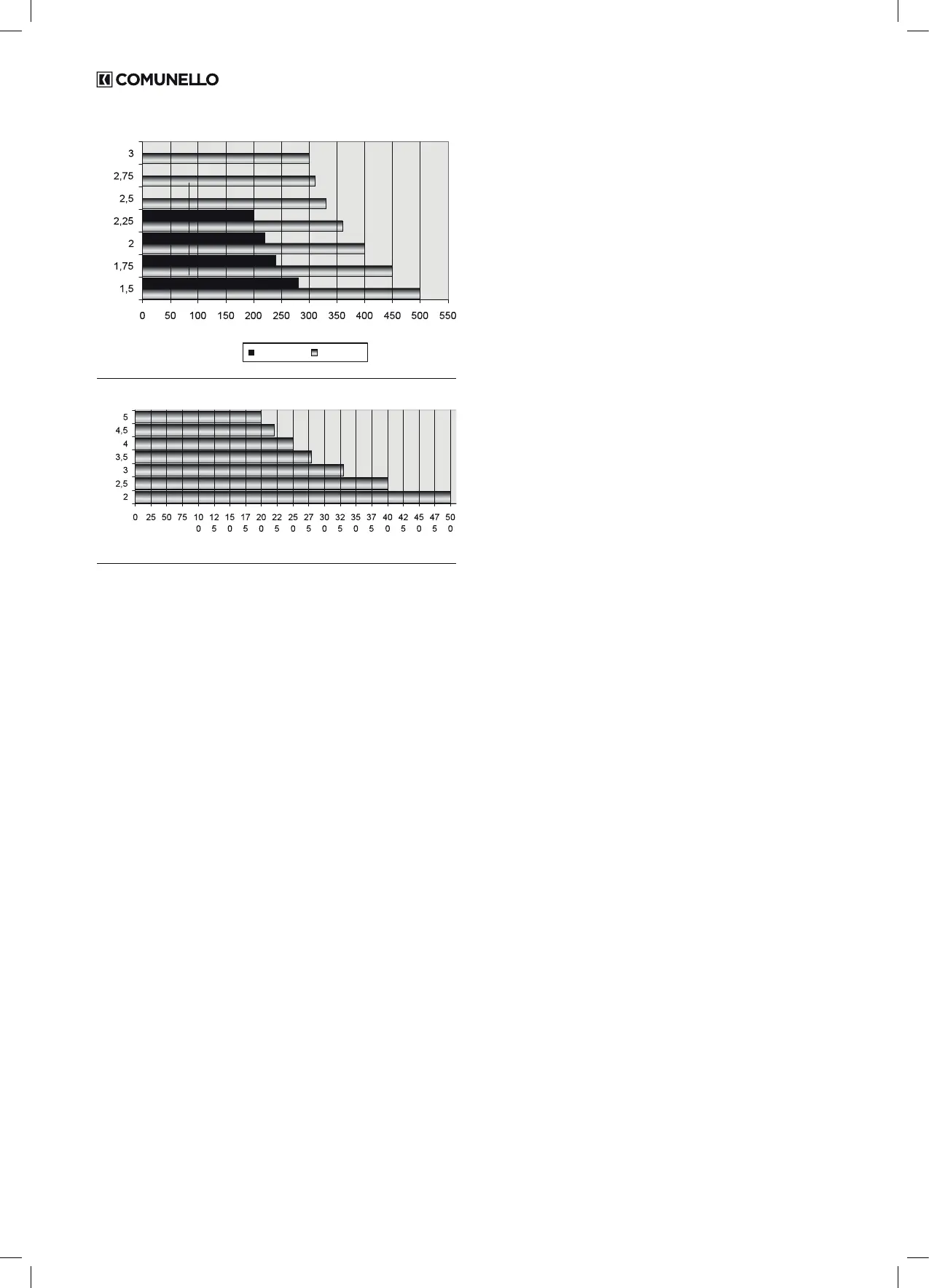

LEAF WEIGHT (Kg)

LEAF LENGHT (m)

LIMITS OF USE - RAM 500

Loading...

Loading...