MOUNTING BRACKET

WEDGES

SEE STEP 1

BASE

STEP

RISER

HANDRAIL

SHORT HANDRAIL

POST

LONG HANDRAIL

POST

PARTS LIST

HARDWARE TOOLS REQUIRED FOR ASSEMBLY:

Qty Description Qty Description • Mallet or hammer and block of wood

2 - Bases 22 - #10 x 1-1/4” Screw • Phillips Screwdriver

2 - Side Panels 2 - Label - No Jumping/Diving • Cordless Drill Motor

2 - Handrails 2 - Mounting Brackets • 1/8” Drill Bit

2 - Long Handrail Posts • Knife

2 - Short Handrail Posts • Pliers

4 - Risers • Liquid Soap or Spray Lubricant

4 - Steps (with 16 wedges) • Sand (approximately 40 lbs.)

See Step 1

Make sure

wording is facing

forward.

2

CONFER-STEP MODEL # STEP-1

Inpool Steps from Confer Plastics

NOTE : FOR INSTALLATION ON FLAT BOTTOM

ABOVE GROUND POOLS ONLY. NOT FOR

DISHED/SLOPED BOTTOMS

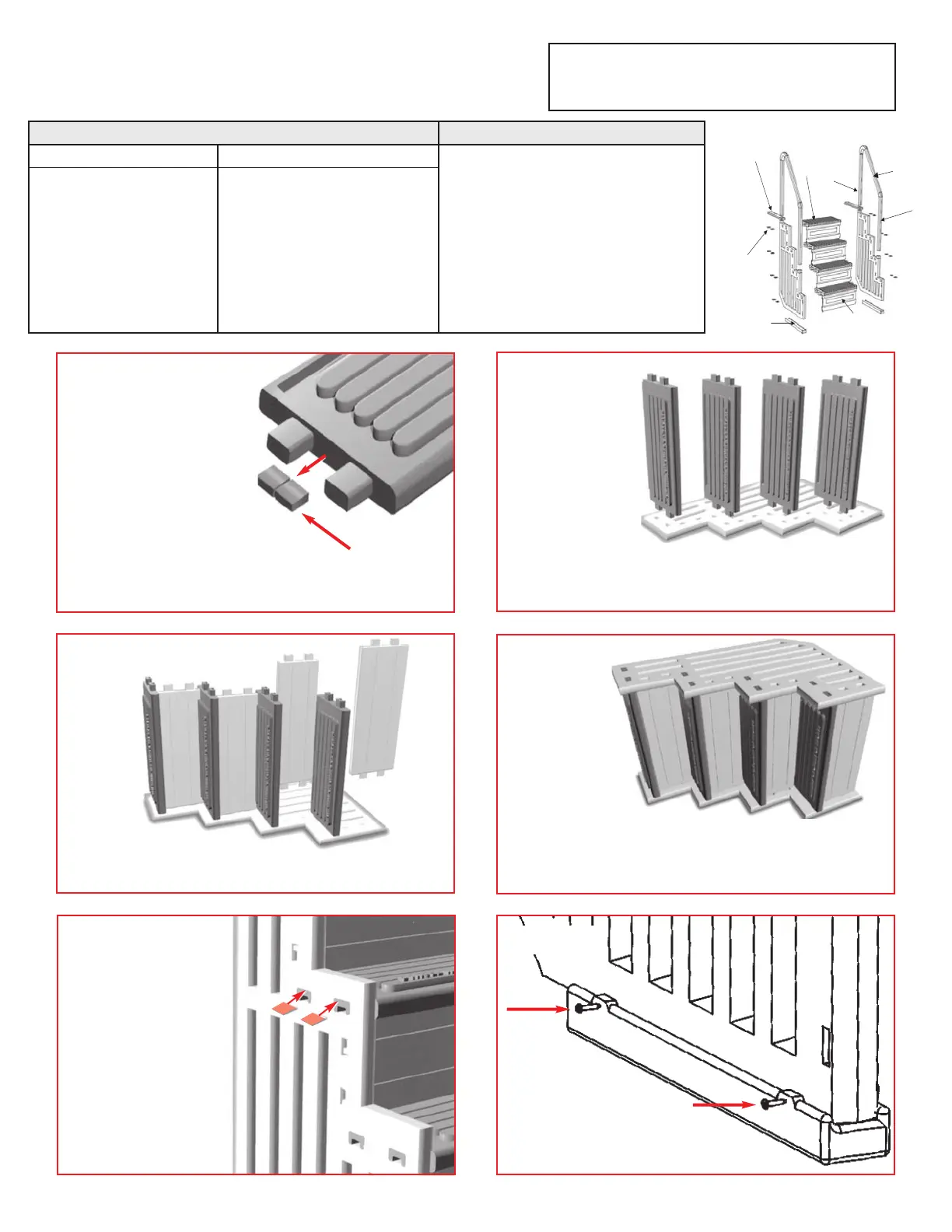

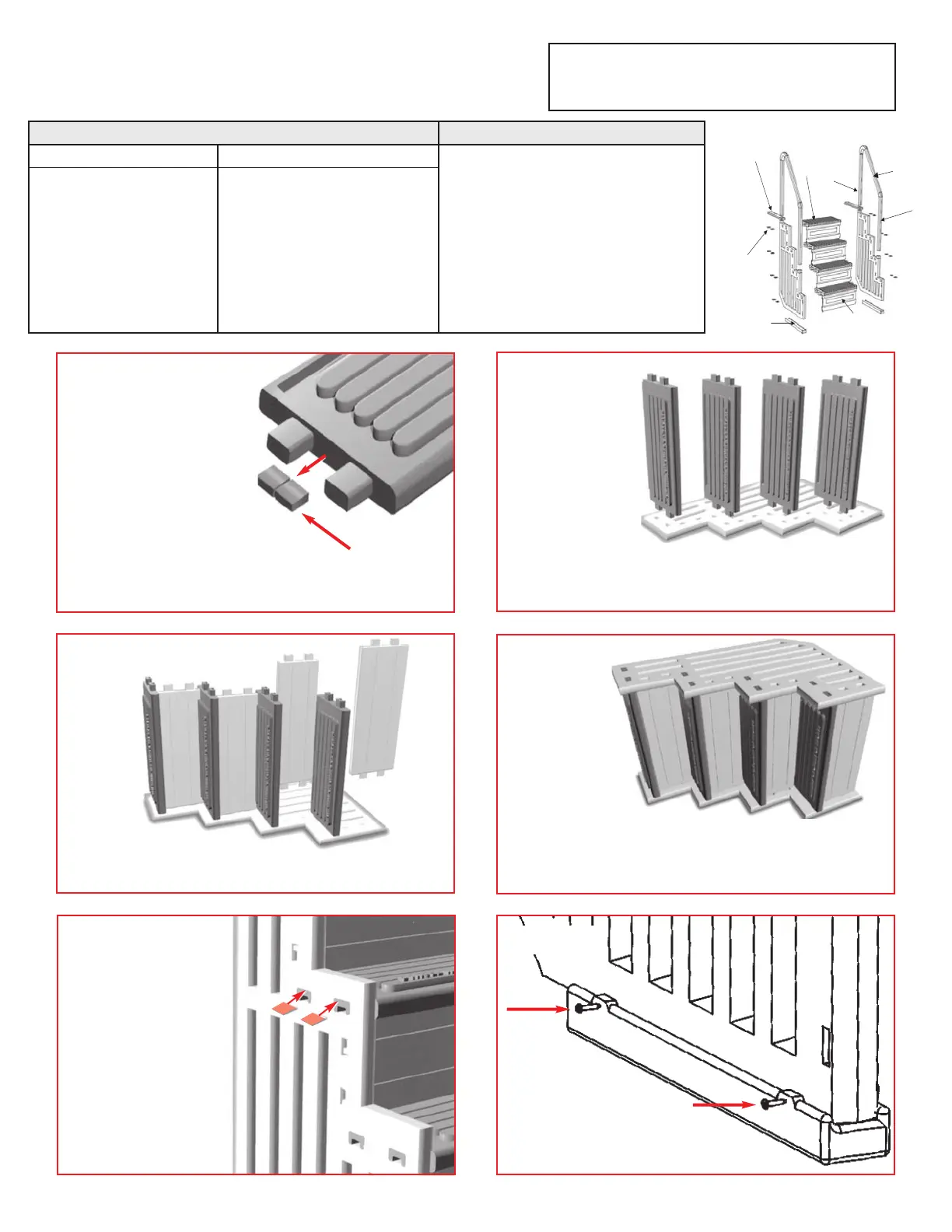

Using pliers remove the

locking wedges from both

ends of each step

and SAVE.

The four handrail posts

are joined together as one

unit and must be separated

before starting assembly.

Using a sharp knife, carefully

cut the posts apart. When

finished you will have two

long posts and two short

posts as required in step #7.

Secure each step by

fully inserting the locking

wedges, saved from

step #1, between the

side panel and the top

surface of both ends of

each step.

Step 1

Step 3

Step 5

Step 6

Step 4

Lay one of the

side panels down

on a clean, flat

surface. Push the

end of each step

into the openings

of the side panel. Make sure that the riser groove in the top of each

step is lined up with the riser recess in the side panel and the

engraved markings “Danger No Jumping/No Diving” are facing

toward the front of the unit.

Position the base

under the side panel.

Secure the base to each

side panel with four #10 x 1-1/4”

screws. Use the molded locators on

each tab of the base.

Step 2

Remove wedges

and save for Step 5.

Insert a riser between each of the steps so that the ends of the risers

align in the riser recesses on the same panel.

Note: Position riser so center hole faces “back” of steps.

Position the second side panel over the steps and risers and press

the panel down so that each step and riser are fully seated into the

second side panel. It may be necessary to tap the side panel, using

a mallet or a hammer and block of wood, to fully seat it.

Loading...

Loading...