35

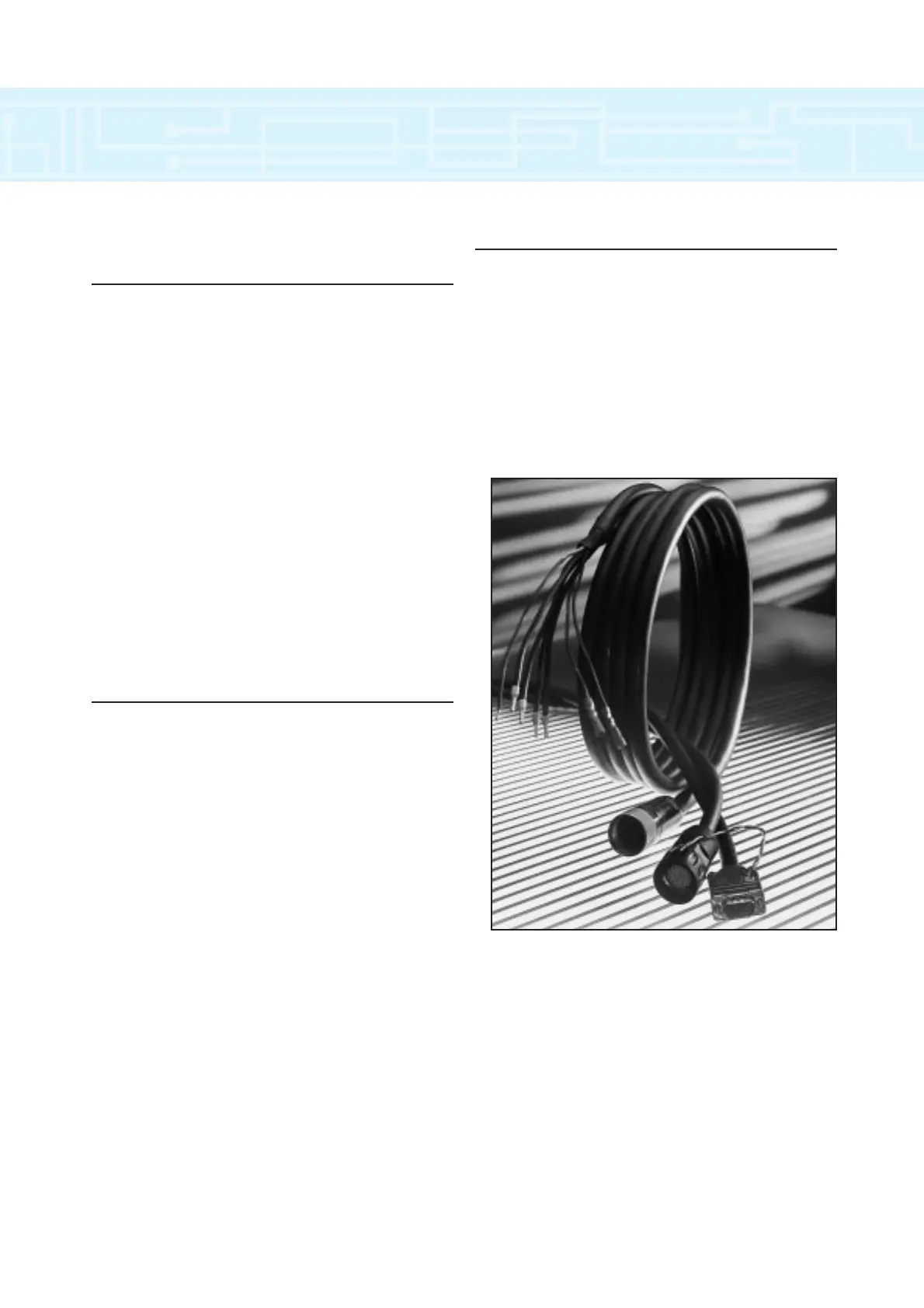

Cable Assemblies

Characteristics - Power and Signal Cables

Cables are an important part of a servo system

installation. Not only must the noise immunity and

integrity of the cabling and connectors be correct, but

SAFETY and EMC regulations must be complied with

to ensure successful, reliable and fail-safe operation.

One of the most frequent problems experienced by

motion systems engineers is incorrect wiring

connections of the motor to the drive.

Control Techniques’ ready-made cables mean

system installers can avoid the intricate, time

consuming assembly normally associated with

connecting servo systems. Installation and set-up

time are greatly reduced - there is no fiddling with wire

connections and crimp tools, and no fault finding. The

cables are made to order in lengths from 3m to 100m

and are available for all standard Unimotor options.

Features

• UL and CSA approved

• Power and signal cables available

• No need for crimp and insertion / removal tools

• Production build gives quality and price benefits

• Compatible with Unimotor and Unidrive

• Optimum noise immunity

• Oil resistant PVC signal cable for industrial

environments and some dynamic applications

• PUR power cable for oil resistance and long life

dynamic applications

• Brake wires are separately shielded within power cable

• Thermistor wire pair is separately shielded in signal cable

• Encoder power pair each 1mm

2

conductors in

signal cable for low volt drop

• Braided screen for greater flexibility and wear

• Power cables with or without brake

• Shielded brake supply wires

• Cable assembly type identification label

Applications

• For general applications choose PVC type. This has

good all round performance.

• Use PUR for high dynamic applications where cable

is frequently in motion.

• Use PUR for machine tools where the cable is

sprayed with coolant fluid.

• 2.5 mm

2

conductors are applicable to all motors in

the range to 142 frame size.

• 4.0mm

2

conductors are applicable to 190 frame sizes.

accessories

Loading...

Loading...