12

•

Extract the piston (C);

•

Replace the O-ring (A) with a new one;

•

Undo the nut securing the piston to the rod;

•

Replace the piston (C) with a new one;

•

If necessary, also replace the rod guide (D);

•

Refit all parts in reverse order.

SPIN UNIT

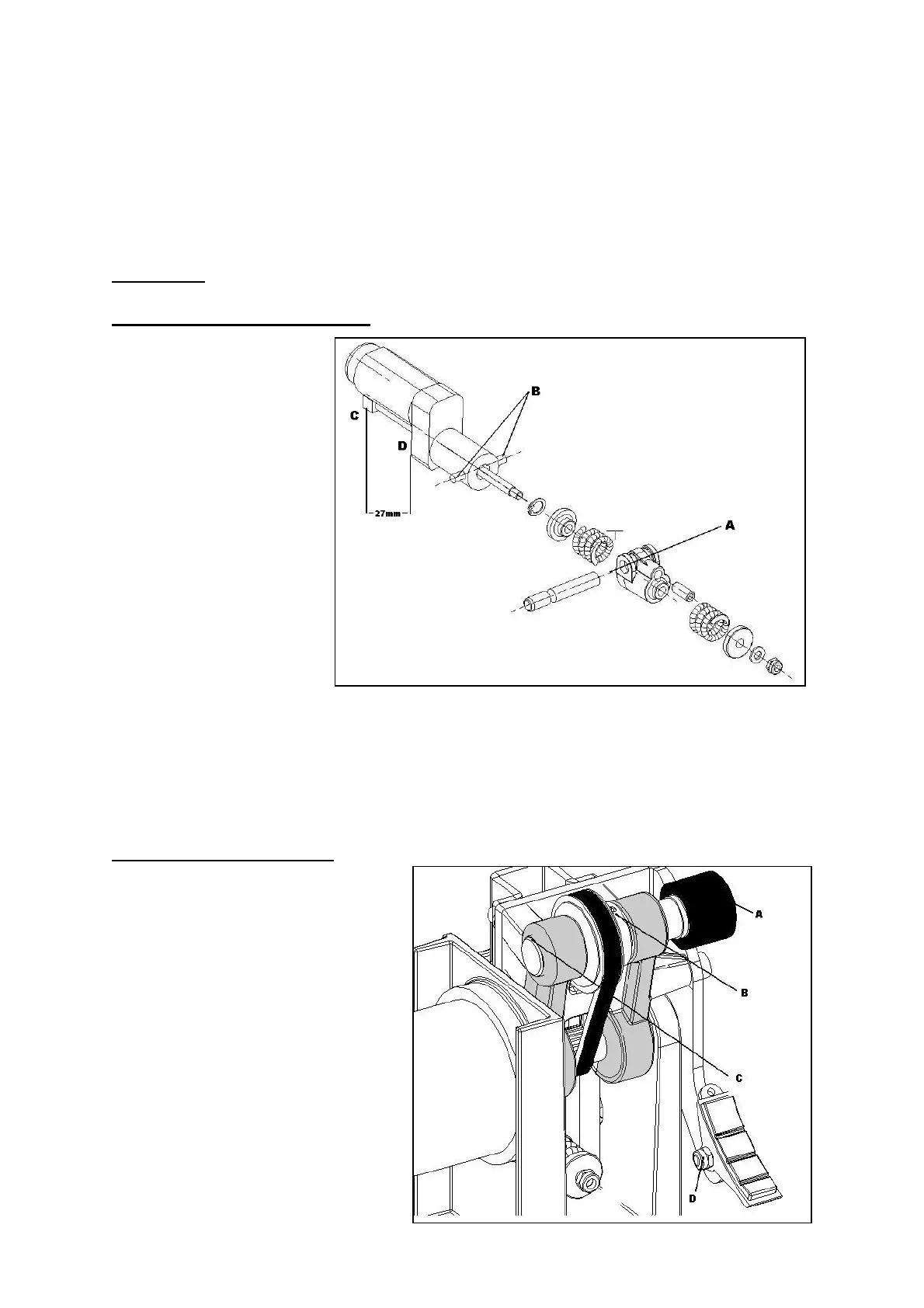

Replacing the electrical actuator

-

Disconnect the power

and actuator signal cable

(brush mount side);

-

Remove the two caps

on the side panel next

to the spin unit;

-

Screw a 5 x 50 bolt into

the cylindrical stud (A);

-

Extract the cylindrical

stud;

-

Unscrew the two actuator

fulcrum screws (B);

-

Remove the electrical

actuator;

-

Check that the rear

block of the new

actuator (C) is located

27 mm away from the stop (D);

-

Fit the new actuator, positioning its various components in the sequence shown in the figure.

-

Apply medium strength threadlocker (loctite243) to the two fulcrum screws (B) and

screw them onto the actuator.

-

Fit the cylindrical stud (A).

-

Close the weight-holder lid again.

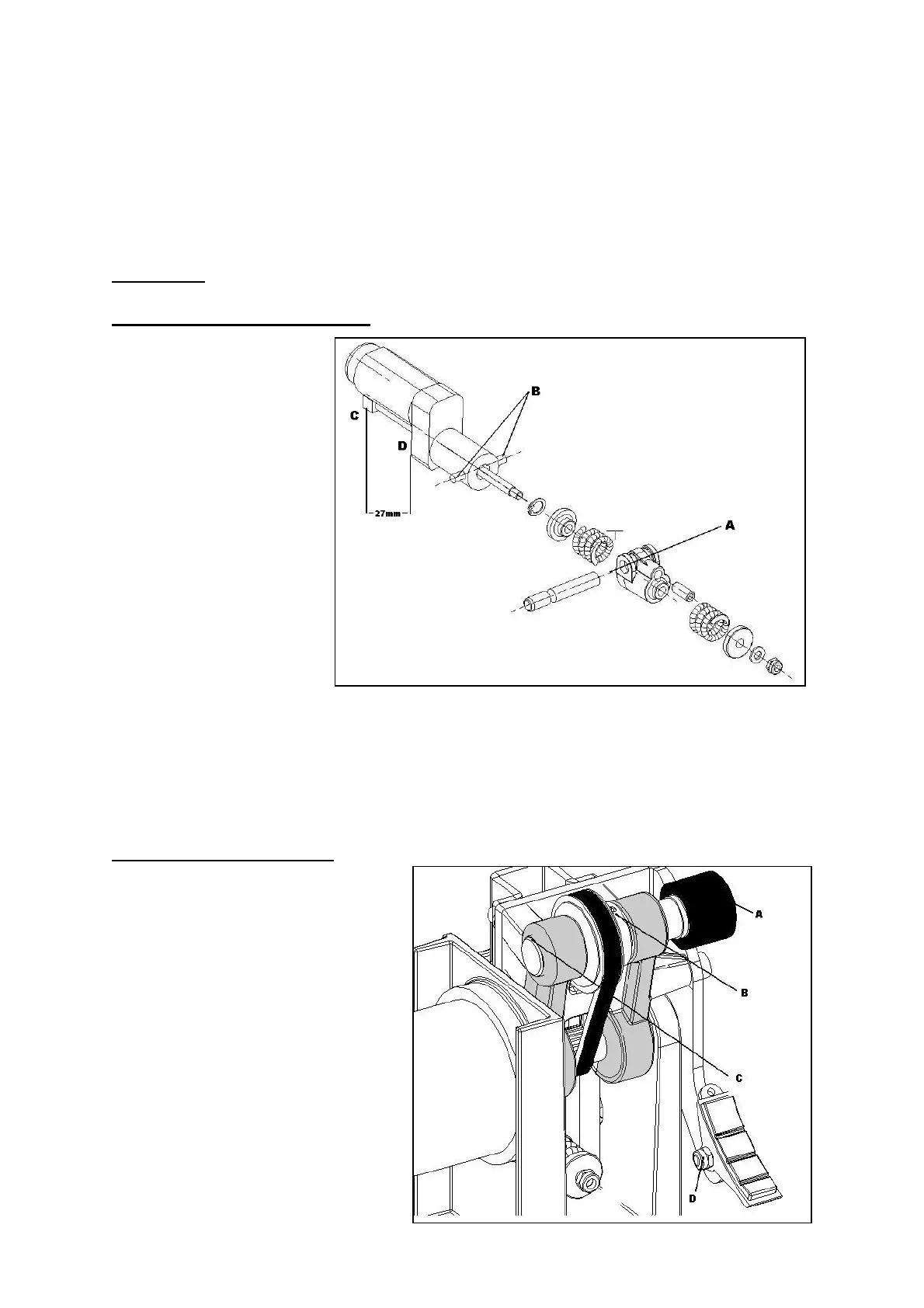

Replacing the friction roller

-

Remove the weight-holder lid.

-

Remove the circlip (C);

-

Unscrew the stud bolt (B);

-

Extract the shaft and friction roller

(A);

-

From the old part, recover the

other circlip and the thrust

washers, which must be mounted

in the same positions in which

they were before replacement of

the roller;

-

Refit the new shaft in reverse

order, making sure that the hole in

stud bolt B is aligned with the flat

seat on the shaft.

Loading...

Loading...