Installation, Operation

& Maintenance Manual

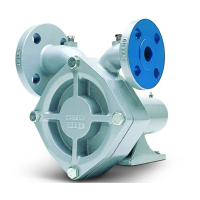

Regenerative Turbine Pumps

for LPG, NH

3

, and Many Other Liquefied Gases and Thin Liquids

All Models 060, 075, and 150

ORIGINAL INSTRUCTIONS IF102H

Direct Mount

ASME Class 300 RF (ANSI) Flange (DLF) and DIN Flange (DLD)

Frame Mount

ASME Class 300 RF (ANSI) Flange (FF) and DIN Flange (FD)

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of

Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken

products must comply with Corken instructions, applicable laws and safety standards. (4) Transfer of toxic, dangerous, flammable or

explosive substances using Corken products is at user’s risk and equipment should be operated only by qualified personnel according

to applicable laws and safety standards.

Scan QR code to view list

of maintenance videos.

Solutions beyond products...