V

Victoria MontgomeryAug 2, 2025

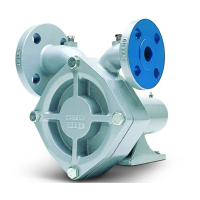

What to do if my Corken Z Series Water Pump runs but there is no flow?

- JJoshua WilliamsAug 3, 2025

If your Corken Water Pump runs but there is no flow, check the valves to ensure they are open, paying special attention to the internal tank excess flow valve. If the excess flow valve is slugged, stop the pump until the valve opens. If the problem persists, reduce the pump speed or install a new or larger excess flow valve. Also, a broken shaft or a defective meter can cause this issue. In the first case, disassemble and inspect the pump, repairing as needed. In the second case, service the meter.