Technical Support Manual – 05/2018 Rel. 2.1.3 Page 34

10. TROUBLESHOOTING

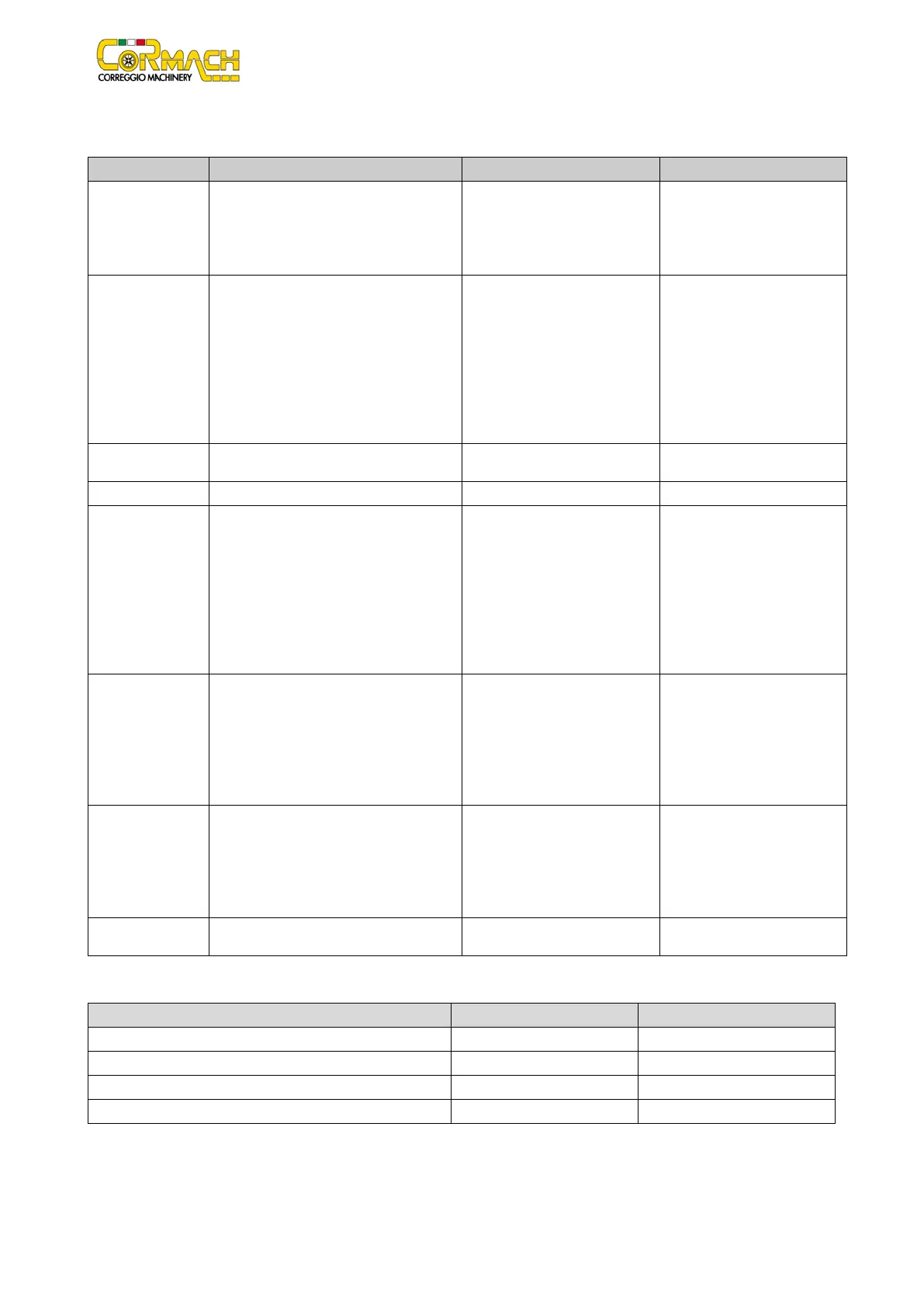

Table 10.1: Troubleshooting table

ENCODER DISC

• It does not read all the positions (0 ÷

255).

• The shaft does not stop rotating.

• The shaft performs a ½ turn and then

• Encoder disc dirty.

•

interrupted.

• Encoder board burnt.

• Clean the encoder disc.

• Replace the board and

then the cable.

PICK-UP SIGNALS

The values displayed are too high.

• The values displayed are too low.

• The value displayed is 0.

The value of the signals must range

between 70 ÷ 110.

welded on the pick-up.

•

connected to CPU.

• Pick-up over compressed.

Weld the cable to the

pick-up.

•

connection of the pick-

up cable to the CPU.

•

compression springs and

make sure that the pick-

DISPLAY

• One or more segments fail to switch

• CPU board burnt. • Replace CPU board.

One or more keys failed.

CPU board burnt.

Replace CPU board.

VFC

• The values displayed are too high.

• The values displayed are too low.

• The value displayed is 0.

•

When knocking the machine the

values do not change.

The value of the VFC must range between

40.0 ÷ 44.0.

•

welded on the pick-up.

•

connected to CPU.

• Pick-up too compressed.

• Weld the cable to the

pick-up.

•

connection of the pick-

up cable to the CPU.

•

compression springs and

make sure that the pick-

SENSORS

• The sensors fail to detect the wheel

dimensions.

• Sensors deactivated.

• Sensor cable interrupted.

• Sensor board burnt (the

sensor calibration program

calibration values).

• Re-

activate the sensors

(See paragraph 4

"PARAMETERS MENU

ACCESS").

• Replace the interrupted

cable.

MACHINE

• The machine does not switch on. • Fuse on socket.

• Power supply.

• Power supply board.

•

fuse.

• Check and replace power

supply.

• Check and replace power

MOTOR

Short-circuited motor.

The fuse

blows upon activation of the motor.

Disconnect the motor from

Replace the motor.

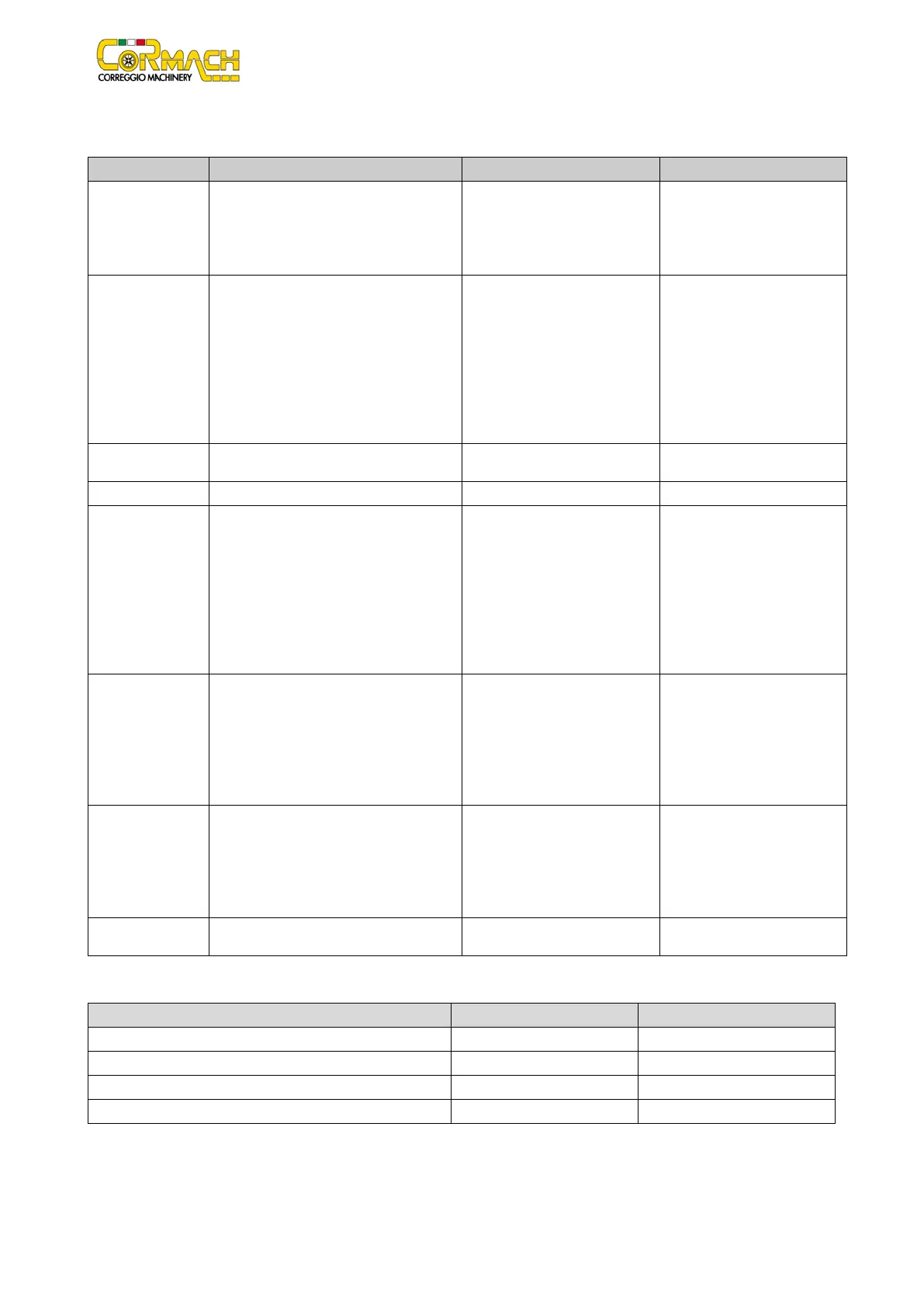

Table T10.2: Parameter reference values

Frequency of the converter voltage-frequency

Loading...

Loading...