Electrical Wiring and Bonding

The automatic cover system must be bonded to meet the National Electrical Code. Bond both tracks to the mechanism by

attaching a bonding lug to the guide feed screw and running a #8 solid copper bond wire to the mechanism.

Bond the lid to the mechanism by drilling a hole in the lid at either end and attaching a bonding lug. Run bond wire from this lug

to the mechanism.

All brackets and any other metal over 4” long should likewise be bonded to the mechanism. There should be a bond wire

extended from the equipment pad to the cover box, so it too can be attached to the mechanism.

Note: Builder is responsible to bring proper electrical lines, conduit and bonding to the mechanism. Electrical

wiring diagram and details are shown below.

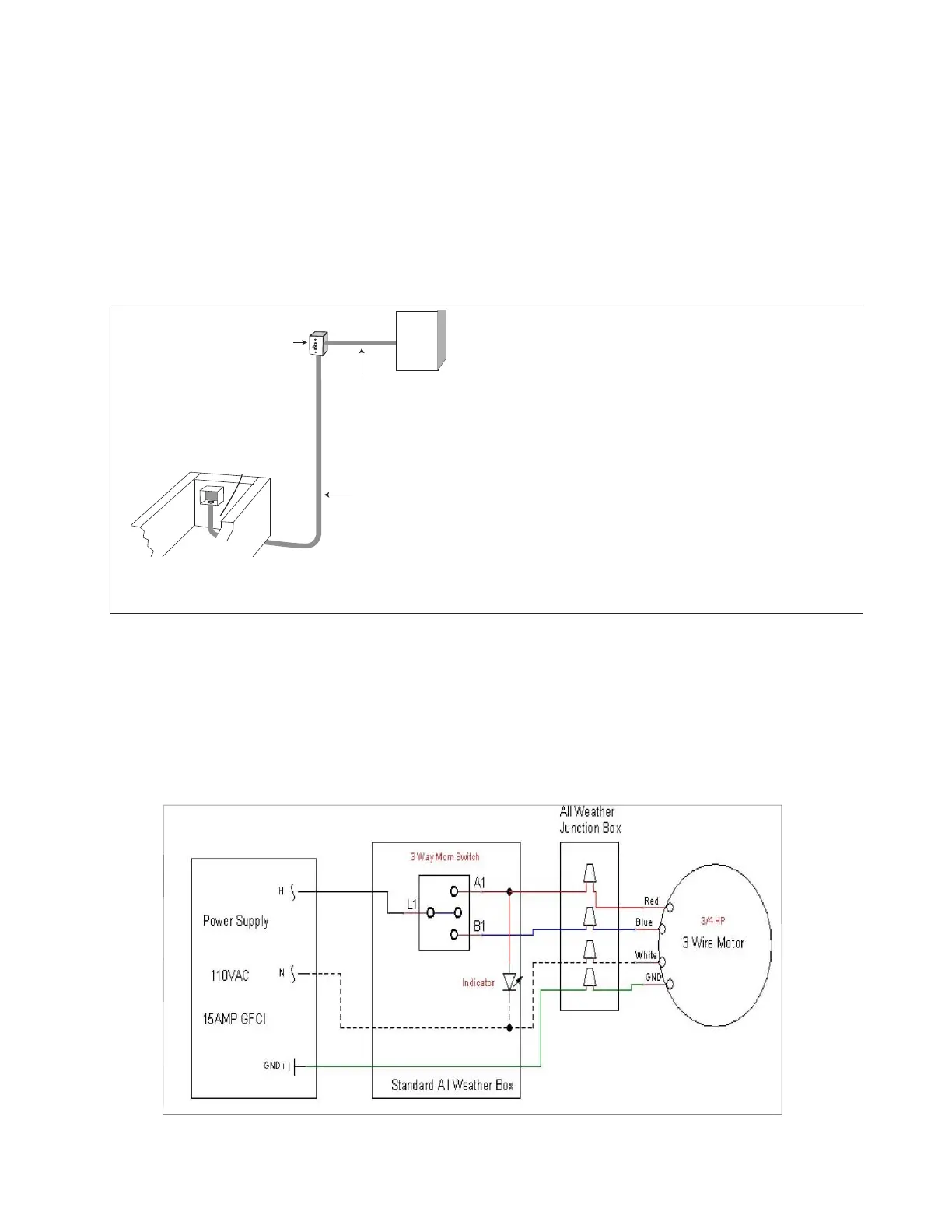

Wiring the Electrical Switch

The control switch must be mounted in an all-weather box, in a location where 100% of the pool is visible.

Connect the control switch according the diagram below.

© Latham Pool Products, Inc. 2019. All rights reserved.

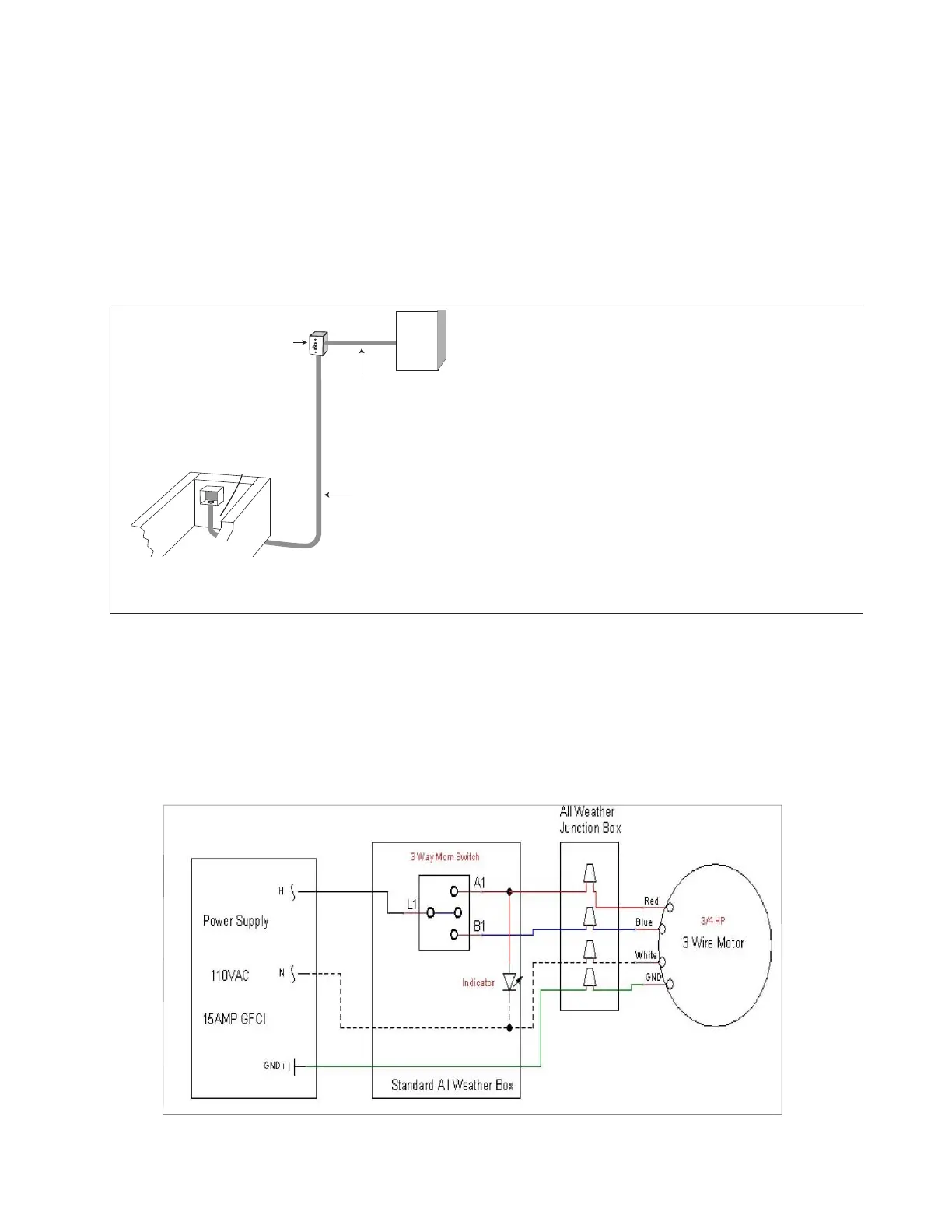

#8 bond wire

Conduit with 4 wires

(2 directional wires, neutral &

unbroken ground)

Single gang all-weather box mounted on

corner of end wall of cover vault approx. 3”

from top of deck.

Key switch is mounted in a standard all-weather

UL listed, single gang box. The box must be

mounted 60 inches off the ground and in a

location where 100% of the pool is visible.

It is recommended that this switch be mounted

halfway along the side of the pool, and within 12

ft of the waters edge.

Conduit with 3 wires

(hot, neutral & unbroken ground)

Note: wires must be sized to meet all

applicable codes. Motor draws 8.8 amps.

Sub-panel with

dedicated

110 Volt,

15 amp breaker

and GFCI

Ground Fault Circuit Interrupter

A GFCI must be used in the electrical supply line for the motor.

This should be on a separate dedicated circuit only for the pool cover.

Key Switches

Mount a standard, single gang, all-weather junction box for the key switch at a

point where 100% of the pool is visible. This is a mandatory requirement to meet

ASTM safety standards. The key switch should not be placed in the mechanism

box. This does not meet UL code.

Options

Coverstar has several different wiring options that include limit switches

wireless remote control, water feature shutoffs, etc. See your Coverstar

distributor for details.

Running Wires

Bring 110V to the key switch. From the panel to the key switch, run 3 wires

(hot, neutral & unbroken ground). From the key switch to the motor end of

the housing, run 4 wires (2 directional, a neutral and an unbroken ground).

Terminate the wires in a weather tight “J” box. The motor is 110V, 3/4 HP

with full load amperage of 8.8 amps. Follow all applicable codes regarding

wire size, grounding, connections, etc.

Loading...

Loading...