24/7 Technical Support- Toll Free 1-877-472-8200

10

Concrete Polishing Solutions- G-290 Operator’s Manual

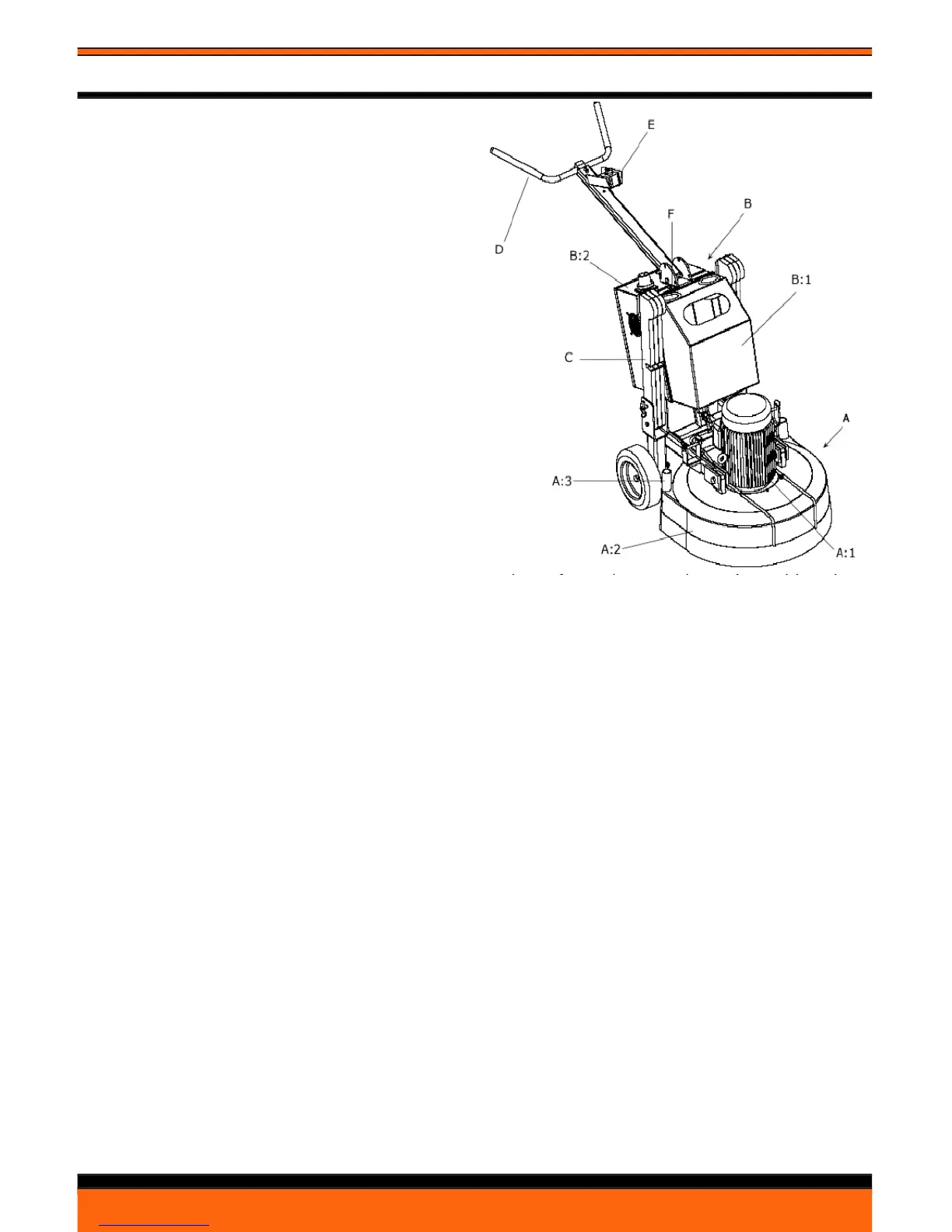

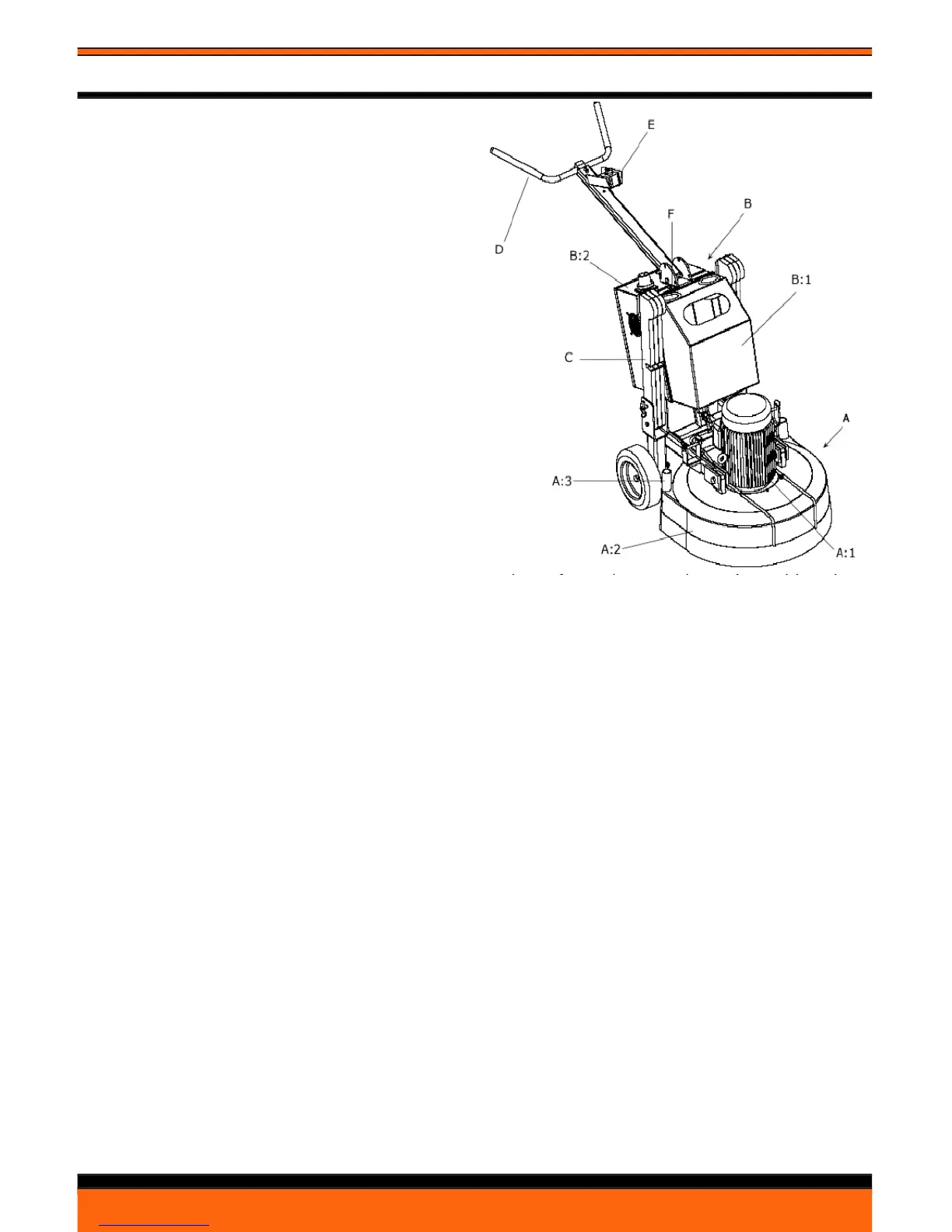

ALL ABOUT YOUR G-290

(metal bonds, resin bonds, etc.) depending on the

surface to be worked.

The gear drive system has been designed with a heavy duty belt that reduces

slipping and extends the life of the machine. We have paid special attentions to the

designing of upper and lower external seals for the head, which prevents dust from

getting to the internal seal and locking up bearings. Both the grinding plates and

gear drive assembly are enclosed in a safety shroud (A:2) which has two dust exhaust

ports (A:3) to be used when dry grinding.

The chassis (B) comprises a water tank (B:1) and an inverter box (B:2) with fan on

one side and an exhaust lter on the other. The water tank is large enough to hold

approximately 8 gallons of water. The water is gravity fed and released by using the

water valve (B:3) located at the bottom of the frame.

The

G-290

is unique in that the weights © are attached to the frame, which prevents

loss while maintaining an orderly job site. They provide 72lbs of additional weight

and are located on both sides of the machine. They can be lowered independently

on either side to help cut and edge more eciently.

The frame of the machine extends above the chassis and holds the self-adjusting

handlebars (D) and the control panel. The control panel (E) includes the speed setting

which has a wide range of speed control, allowing you more room to dial each tool to

its optimum cutting speed.

The

G-290

has been designed by the

engineers at Concrete Polishing Solutions

to be the most innovative in grinding

and polishing technology. We have used

our experience in the industry to create

a grinder and polisher that combines

practicality and durability.

The grinding head assembly (A), contains

the motor (A:1), the grinding plates are part

of the revolutionary three-head grinding

system designed by CPS. This new system

contours to the oor’s surface, reducing

rigidity, allowing your tooling to better

follow the oor’s surface, and lowering initial

diamond costs. These driving plates can be

tted with a number of attachment plates

Loading...

Loading...