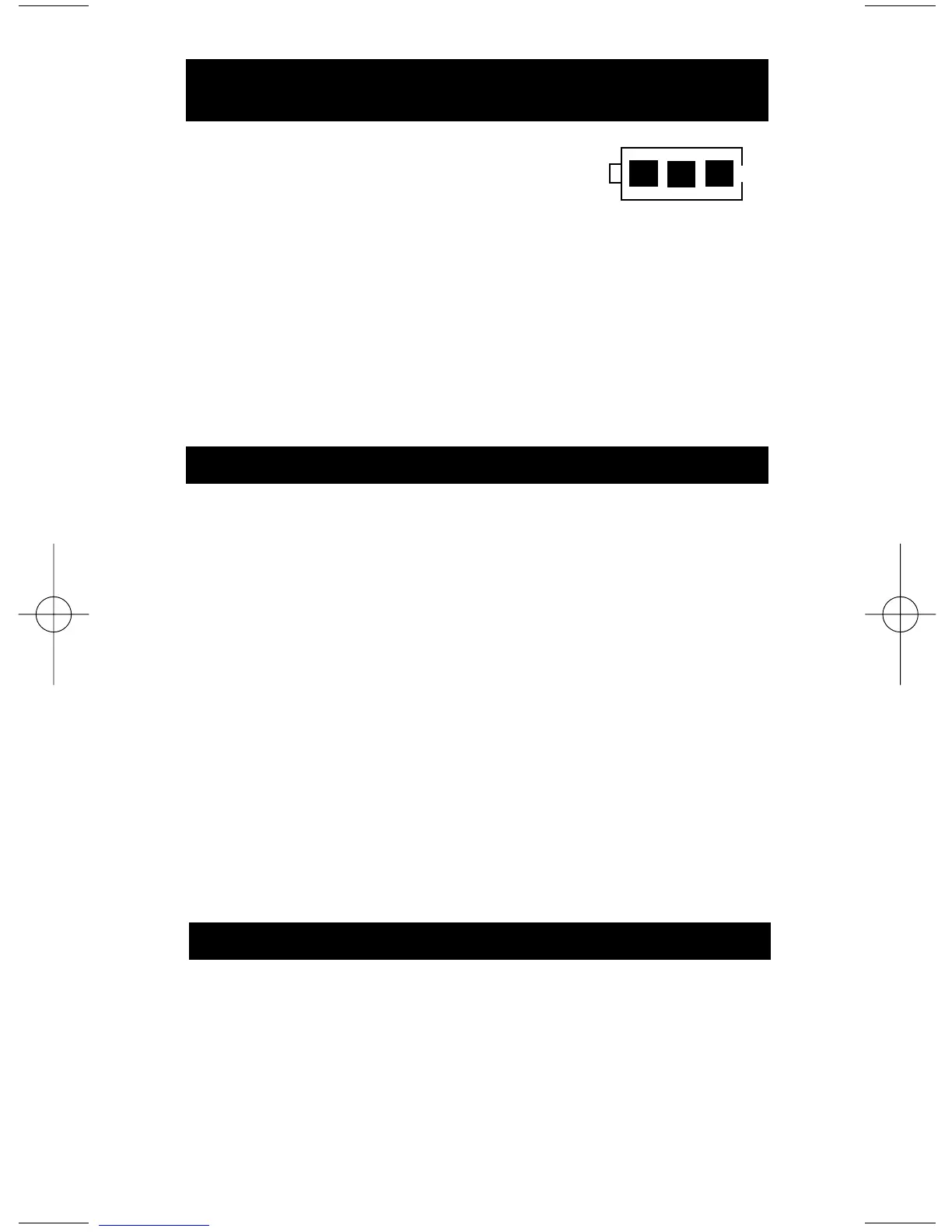

BATTERY INDICATOR

(with BAR GRAPH power level indicator)

100% ( 3 segments ) of Bar Graph-

67% ( 2 segments ) of Bar Graph-

33% ( 1 segment ) of Bar Graph-

0% ( 0 segments ) of Bar Graph-

Dashes across the Display-

Battery at 100% to 80%

Battery at 80% to 60%

Battery at 60% to 20%

Battery at 20% to 5%

Battery below 5%, replace

VACUUM PUMP CHECK

Contaminants quickly form in the oil of a vacuum pump.

The contaminated oil can severely inhibit the performance

of a pump and eventually cause damage to the pump itself.

The VG200 incorporates a unique vacuum pump check

designed to test the performance of a vacuum pump

BEFORE it is used to evacuate a system. Simply attach

the VG200 directly to the vacuum pump and watch the

display as it measures the performance of the vacuum

pump.

Note: Different sizes and brands of vacuum pumps will experience

varied results. Check the specifications published by the

manufacturer of your vacuum pump to determine the ultimate

vacuum level your pump can achieve. Many published

specifications state that pumps rated between 2 & 8 CFM should

experience an ultimate vacuum between 15 and 50 microns.

SENSOR MAINTENANCE

Note: If the Low Battery indicator does not de-energize after

replacing with a brand new battery, the VG200 sensor is saturated

with Oil or other contaminants. Please proceed with the cleaning

processing below.

The battery indicator is shown on the LCD as a

battery shape with a 3 segment Power Level

Bar Graph:

Note: If the Low Battery indicator cannot be resolved with a new

battery, See Sensor Maintenance section.

Loading...

Loading...