Do you have a question about the Craftsman 315.275 and is the answer not in the manual?

Explains the concept of double insulation in electric power tools for safety.

Covers tool knowledge, work area, electrical safety, apparel, and tool storage.

Familiarize yourself with operating features and safety requirements before use.

Describes the function and installation of the plastic chip shield for protection.

Explains the switch's lock-on feature for extended operation.

Details power supply requirements and precautions for the router's electric motor.

Step-by-step guide for safely installing and removing router cutters.

Instructions on how to engage and disengage the spindle lock mechanism.

Guidance on feed rates, proper techniques, and avoiding force feeding for clean cuts.

Covers general care, solvent use, and limitations on parts for service.

States that bearings are pre-lubricated for the unit's life and no further lubrication is required.

Guidelines for selecting and using extension cords to minimize power loss and ensure safety.

Important note regarding the Double Insulated System and service recommendations.

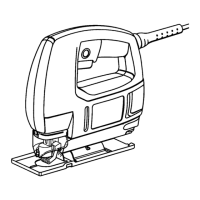

This document is an owner's manual for a Craftsman Double Insulated Router, Model No. 315.275000. It provides comprehensive instructions for safe operation, adjustments, routing techniques, and maintenance. The manual emphasizes safety throughout, with numerous warnings and cautions to ensure user protection and proper tool handling.

The Craftsman Router is a precision-built electric motor tool designed for various routing and edge shaping operations in woodworking. Its primary function is to cut grooves, decorative edges, and patterns into wood. The router operates at a high no-load speed of 25,000 RPM, allowing for clean and smooth cuts when used correctly. It is a versatile tool that can be used freehand or mounted to a router table for different applications. The double-insulated design eliminates the need for a grounded power cord, enhancing safety by isolating internal metal motor components with protective insulation.

The router is equipped with several features to facilitate ease of use and control. It has two handles, one on each side of the router base, designed for a firm grip and proper control during operation. A clear plastic chip shield is installed on the front of the router for protection against flying dust and chips. This shield is designed to fit the front opening of the router base and should always be properly in place during use.

The switch of the router includes a lock-on feature, which is convenient for extended periods of operation. To activate the lock, the user depresses the trigger, pushes in the lock button located on the side of the handle, and then releases the trigger while holding the button in. To release the lock, the trigger is depressed and released again.

Installing and removing cutters involves a spindle lock mechanism located on the top of the end cap. To activate the lock, the spindle lock is pushed in, slid into the lock position, and then released. Cutters are secured with a collet nut, which is tightened or loosened using a provided wrench. The router accommodates both 1/2 inch and 1/4 inch shank bits, with a 1/4 inch collet assembly included for smaller bits. It is crucial to ensure the collet nut is securely tightened to prevent the cutter from coming out during use.

Depth of cut adjustments are a key aspect of router operation. The router allows for depth settings from 0 to 1-1/2 inches. It is recommended that cuts not exceed 1/8 inch in depth, requiring multiple passes for deeper cuts. The depth adjusting ring, with marks indicating 1/64 inch changes, allows for precise depth setting. There are two indicator points, one on the front of the motor housing and another on the base, for reading the depth of cut. When mounted to a router table, the bottom depth indicator ring is particularly convenient.

The manual provides detailed guidance on routing techniques, emphasizing the importance of proper feed rate. The "secret" to professional routing lies in making a careful setup and selecting the correct feed rate. The feed rate should be firm and steady to produce a continuous spiral of uniform chips, avoiding both "too fast" feeding (which can lead to rough finishes, splintering, and motor overload) and "too slow" feeding (which can cause scraping, glazing, burning, or marring of the workpiece). The sound of the motor and the feel of the cut are indicators of the proper feed rate.

Direction of feed and thrust is also critical. The router motor and bit revolve clockwise, creating a slight counterclockwise twist tendency. To guard against kickback, the setup and direction of feed should always involve thrusting the tool against the guide in the same direction that the leading edge of the bit is moving, ensuring continuous biting into new wood.

The manual covers starting and ending internal routing, where the router is tilted onto the workpiece, turned on, and gradually fed into the material. For edging with pilot bits, arbor-type bits with pilots are used to follow workpiece edges, preventing cuts from being too deep or too shallow. Freehand routing allows for versatility in creating signs, relief sculptures, and patterns, with techniques for routing letters or carving out backgrounds. When freehand routing, it is suggested to draw the pattern, choose the appropriate cutter, and rout in multiple passes, not exceeding 1/8 inch per pass. Routing with the straight edge of the subbase against an edge guide or fence is also described for creating parallel grooves.

Maintenance instructions are provided to ensure the longevity and safe operation of the router. The manual stresses the use of only identical Craftsman replacement parts for servicing to prevent hazards or product damage. All other parts related to the double insulation system should be serviced by a qualified Sears service technician.

Cleaning plastic parts should be done with clean cloths, avoiding brake fluids, gasoline, petroleum-based products, or strong solvents, as these can damage plastic. The manual also warns against using the tool for extended work on fiberglass, wallboard, spackling compounds, or plaster, as the abrasive nature of these materials can accelerate wear. Frequent cleaning with an air jet is recommended when working with such materials. Safety goggles or glasses with side shields, and a dust mask in dusty conditions, are advised during cleaning.

The router's bearings are pre-lubricated for the life of the unit, so no further lubrication is required. Instructions for light bulb replacement are also included, involving unplugging the router, removing the cutter, adjusting the router to maximum height, removing screws for the subbase and work light lens, and then pulling the bulb from its socket.

Proper care of cutters is emphasized, recommending that they be kept clean and sharp. Accumulated pitch and gum should be removed after each use. When sharpening, only the inside of the cutting edge should be sharpened, maintaining the original clearance angle. The collet and collet nut also require periodic cleaning to remove dust and chips, ensuring proper performance.

The manual concludes with helpful hints for safe and effective routing, such as clamping the workpiece securely, wearing eye protection, making careful setup adjustments, keeping cutters clean, and planning each operation. It encourages users to "think safety by thinking ahead."

| Model Number | 315.275 |

|---|---|

| Type | Angle Grinder |

| Voltage | 120V |

| Amps | 7.5 A |

| Spindle Thread | 5/8"-11 UNC |

| Wheel Diameter | 4-1/2 in |

Loading...

Loading...