Do you have a question about the Craftsman 351.214600 and is the answer not in the manual?

Wear proper apparel, hair covering, and safety shoes.

Keep work area clean, well-lit, and free of hazards.

Keep tool clean, lubricated, and check for damage.

Operate tool correctly, maintain it, and check for damage.

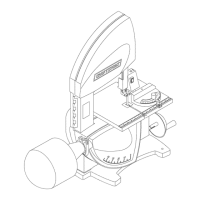

Securely mount the band saw to a stable, level bench or table.

Line up slot on crank handle with pin on shaft and secure.

Place clamp over bag sleeve and secure over dust port.

Horsepower, voltage, amps, Hertz, phase, and RPM.

Operating voltage, frequency, and motor control switch.

Proper grounding procedures for electrical shock prevention.

Guidelines for selecting and using extension cords.

Detailed specs like throat depth, cut depth, table size, and blade length.

Ensure guides are adjusted, blade tensioned, and use proper feed.

Steps to release blade tension and remove the blade.

Steps to install a new blade, tension it, and track it.

Adjusting guide pins and ball bearing for rear support.

Adjusting guide pins and roller for rear support.

Distance from tooth tip to back, affects rigidity and cut radius.

Distance between sides, affects rigidity and tooth strength.

Teeth per inch affects cut smoothness and material compatibility.

Techniques for guiding workpiece free-hand for curved shapes.

Tilting the saw head to achieve angled cuts.

Keep machine, wheels, and mechanisms clean from debris.

Applying oil to mechanisms and wax to the table top.

Replacing worn cords, damaged parts, or missing parts.

Causes like material not secure, blade too coarse, or misaligned guides.

Causes include blade too coarse, inadequate feed pressure, or backwards installation.

Issues like work not square, feed too great, or guides not adjusted.

Causes like too much feed or blade too coarse.

Loading...

Loading...