ENGLISH

6

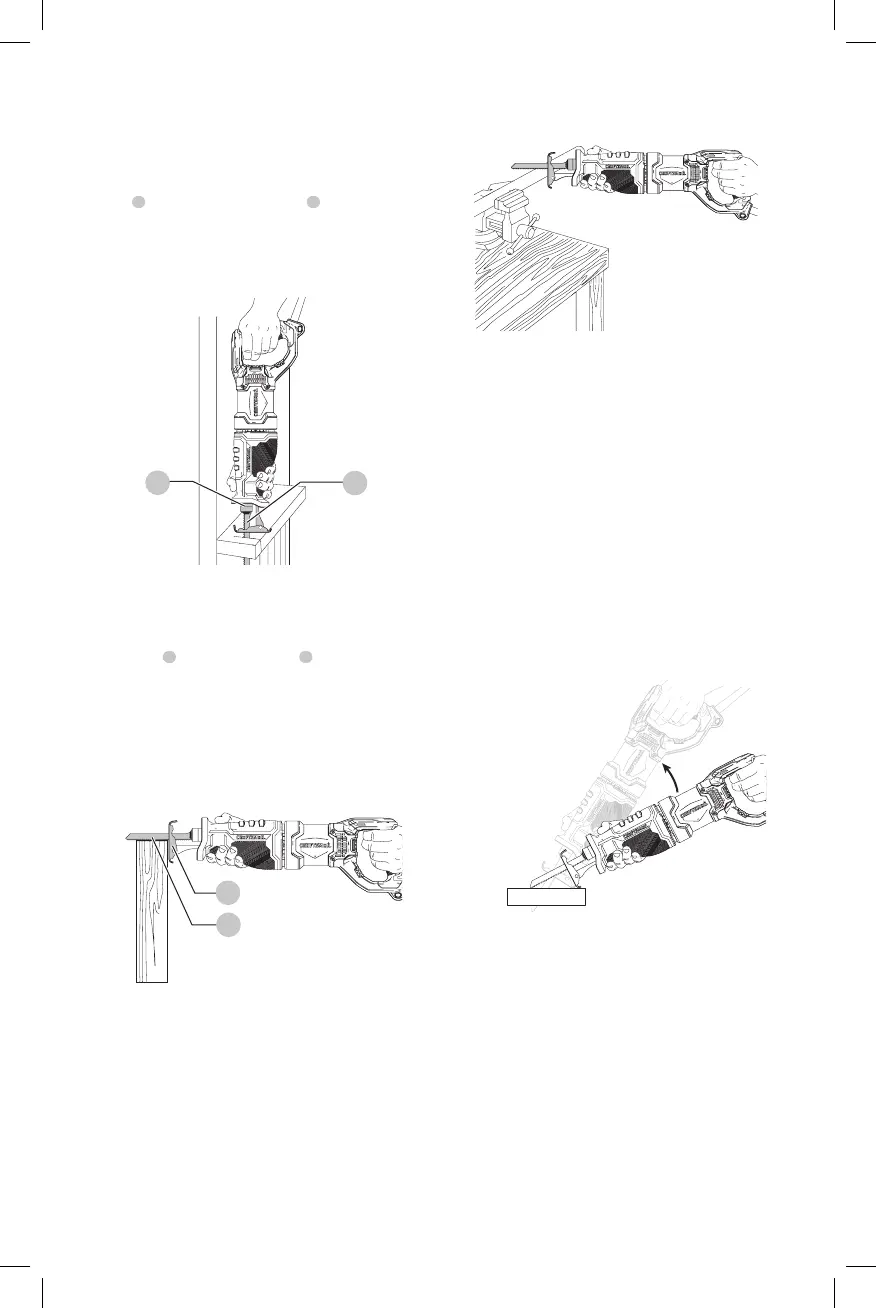

Flush Cutting (Fig. E)

The compact design of the recipro cating saw motor

housing and pivoting shoe permit close cutting to floors,

corners and other difficultareas.

1. To maximize flush cutting capabilities, insert the

blade

7

into the blade clamp collar

6

with the teeth of

the blade facingup.

2. Turn the saw upside down so you are as close to the

work surface aspossible.

Fig.E

7

6

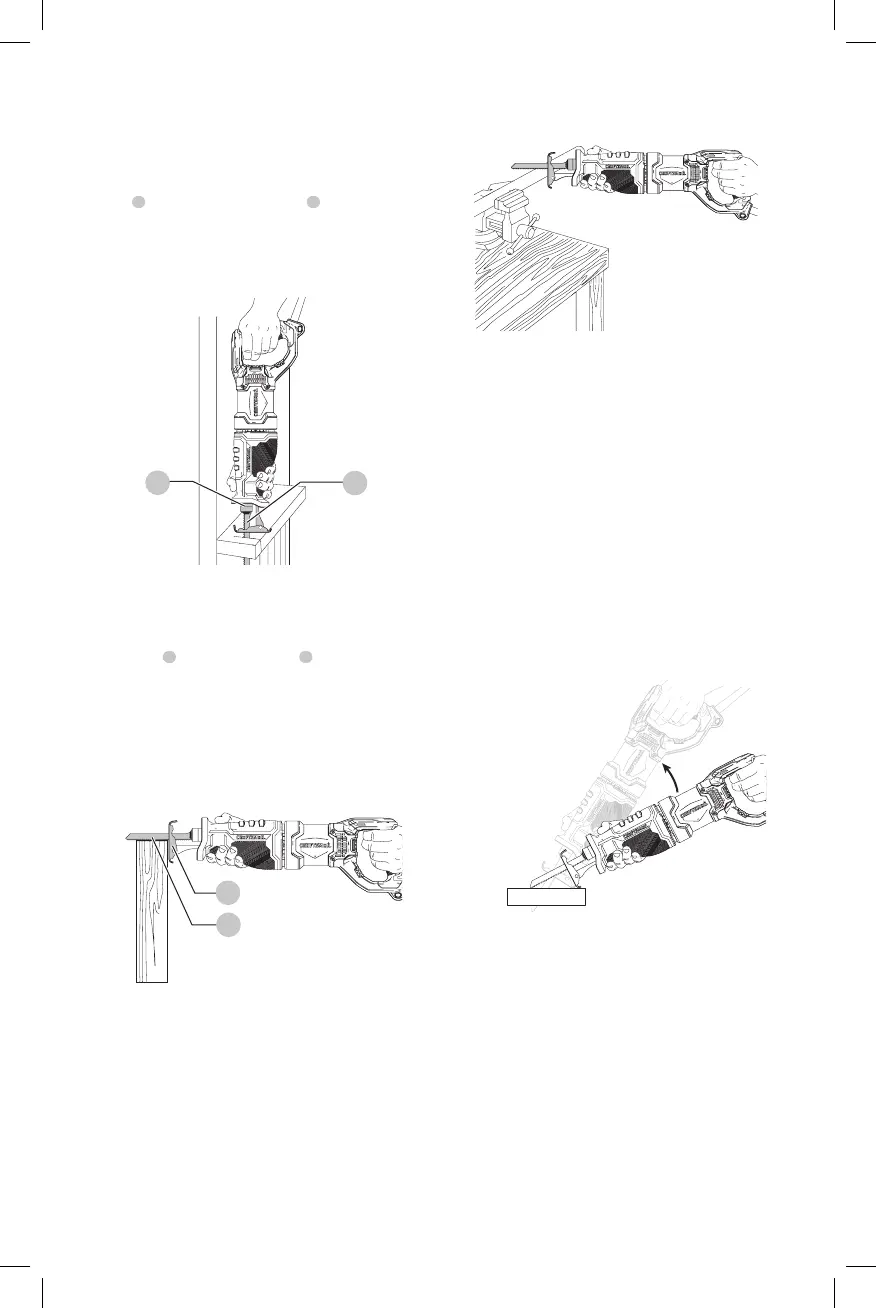

Wood Cutting (Fig. F)

1. Before cutting any type of wood, be sure the workpiece

is firmly anchored or clamped to preventslipping.

2. Place blade

7

and adjustable shoe

5

firmly against

work to becut.

3. Switch on saw motor before starting thecut.

4. Always hold saw firmly with both hands while cutting.

Whenever possible, the shoe must be held firmly against

the material being cut. This will prevent the saw from

jumping or vibrating and minimize bladebreakage.

Fig.F

7

5

Metal Cutting (Fig. G)

1. Use a finer blade for ferrous metals and a coarse blade

for non-ferrousmaterials.

2. In thin gauge sheet metals it is best to clamp wood to

the underside of the sheet. This will ensure a clean cut

without excess vibration or tearing ofmetal.

3. Avoid forcing cutting blade as this reduces blade life

and causes costly bladebreakage.

NOTE: You should spread a thin film of oil or other coolant

along the line ahead of the saw cut for easier operation

and longer blade life. For cutting aluminum, kerosene

ispreferred.

Fig.G

Pocket Cutting - Wood Only (Fig. H)

Measure the surface area to be cut and mark clearly with a

pencil, chalk orscriber.

• Tip the saw backward until the back edge of the shoe

is firmly on the worksurface and the fully extended

moving blade will clear the surface.

• Switch motor on, permitting blade to attain

maximumspeed.

• Grip handle steadily and begin a slow, deliberate

upward swing with the handle of thesaw.

• The blade will begin to feed into material. Always

be sure blade is completely through material before

continuing with pocketcut.

NOTE: In areas where blade visibility is limited, use the

edge of the shoe as aguide.

Fig.H

Project Tips

• Cut only with sharp blades; they cut cleaner, faster and put

less strain on the motor whilecutting.

• When cutting, always ensure that the shoe is resting

against the workpiece. This will improve operator

control and minimizevibration.

• For longer blade life, use bi-metal blades. These

utilize a carbon steel back welded to high speed steel

teeth making the blade more flexible and less prone

tobreaking.

Loading...

Loading...