ENGLISH

8

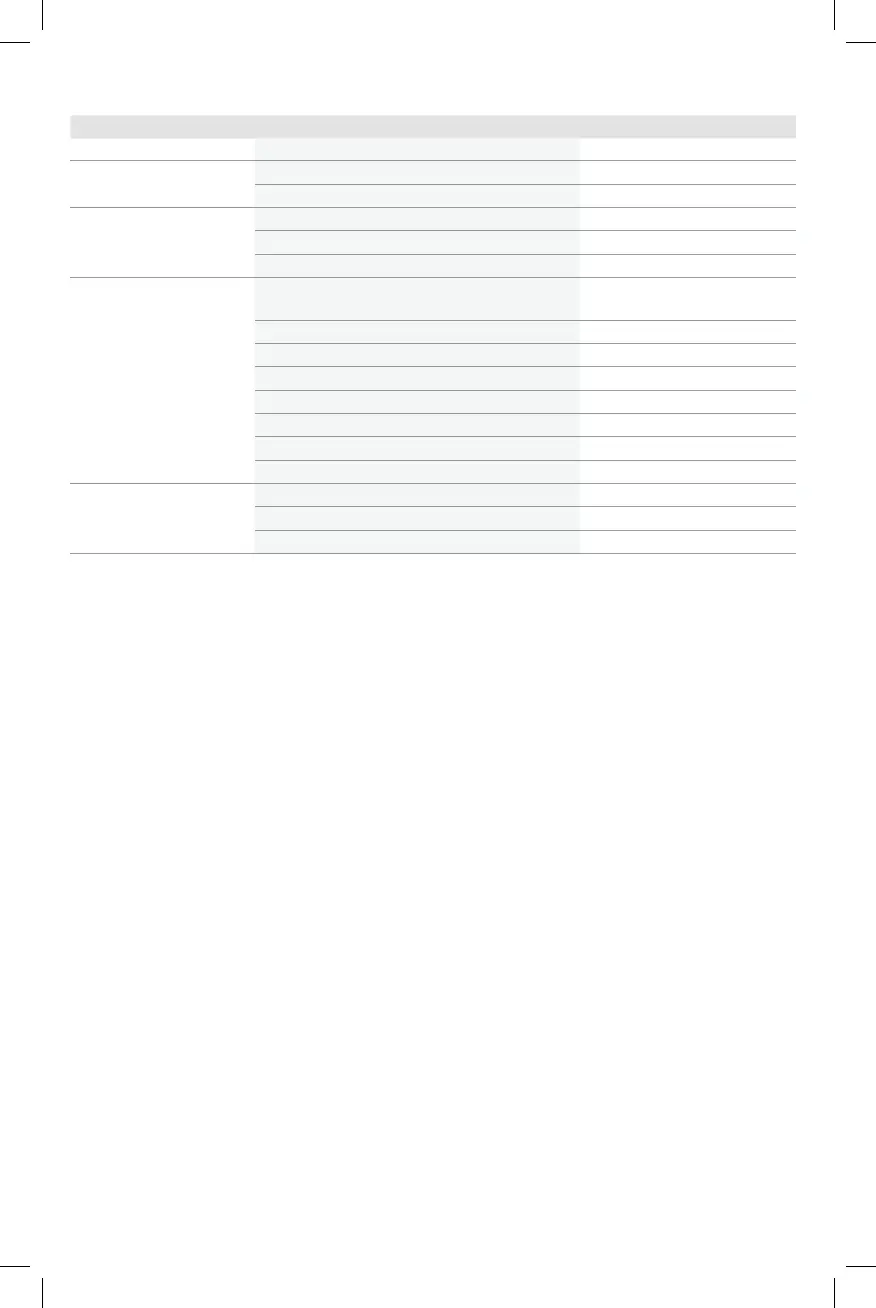

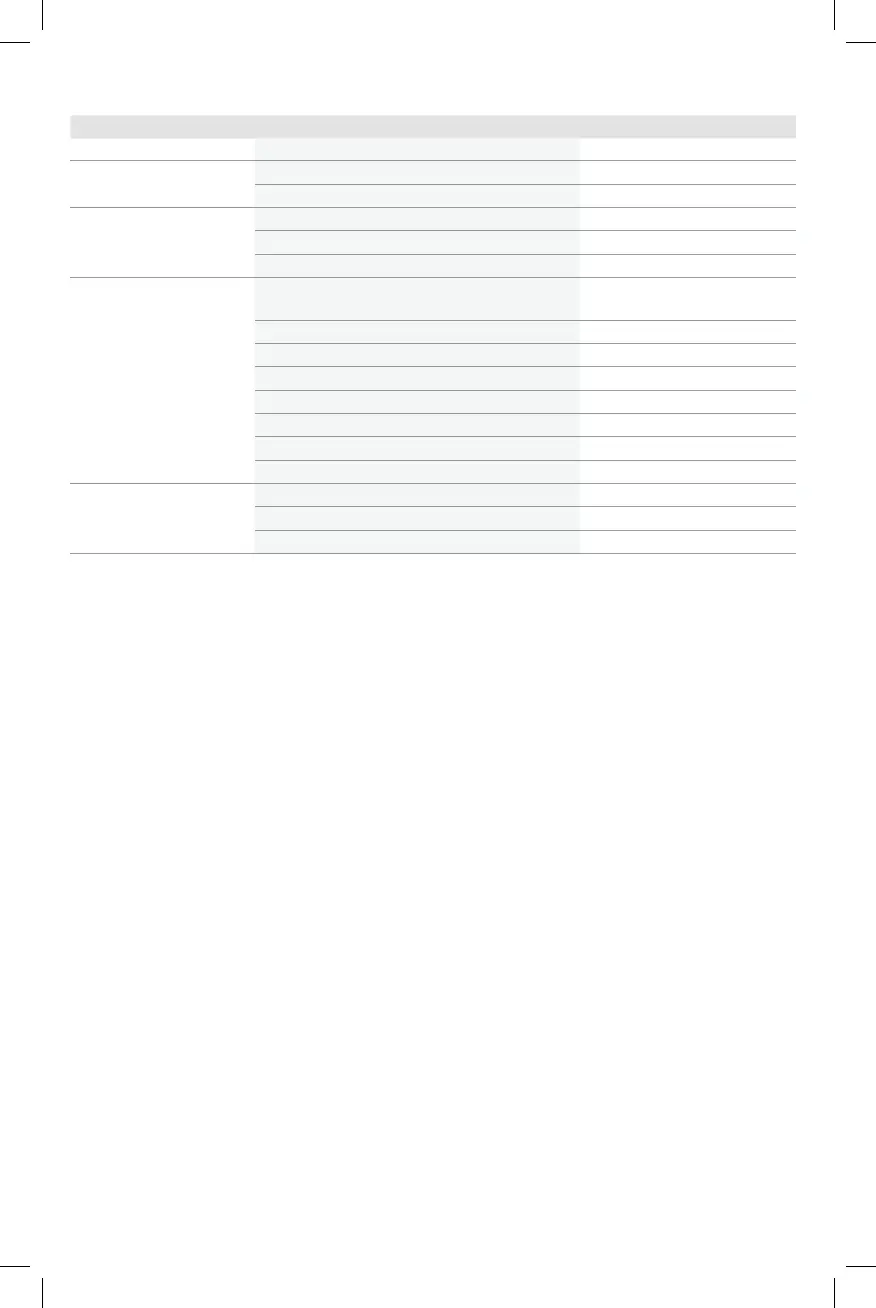

Troubleshooting

Problem Cause Correction

Trigger valve stem leaks air. O-ring/seals cut or cracked. Replace trigger valve assembly.

Failure to cycle. Air supply restriction. Check air supply equipment.

Air supply too low. Check air supply equipment.

Lack of power; slow to cycle. O-rings/seals cut or cracked. Replace O-rings/seals.

Trigger assembly worn/leaks. Replace trigger assembly.

Dirt/tar build up on driver. Disassemble nose/driver to clean.

Skipping fasteners;

-intermittent feed.

Air restriction/inadequate air flow through quick disconnect socket

and plug.

Replace quick disconnect fittings.

Worn piston O-ring. Replace O-ring, check driver.

Damaged pusher spring. Replace spring.

Low air pressure. Check air supply system to tool.

Wrong size fasteners. Use only recommended fasteners.

Broken/chipped driver. Replace driver (check piston O-ring).

Dry/dirty magazine. Clean/lubricate use Air Tool Lubricant.

Worn magazine. Replace magazine.

Fasteners jam in tool. Wrong size fasteners. Use only recommended fasteners.

Bent fasteners. Discontinue using these fasteners.

Broken/chipped driver. Replace driver.

Loading...

Loading...