- 34 -

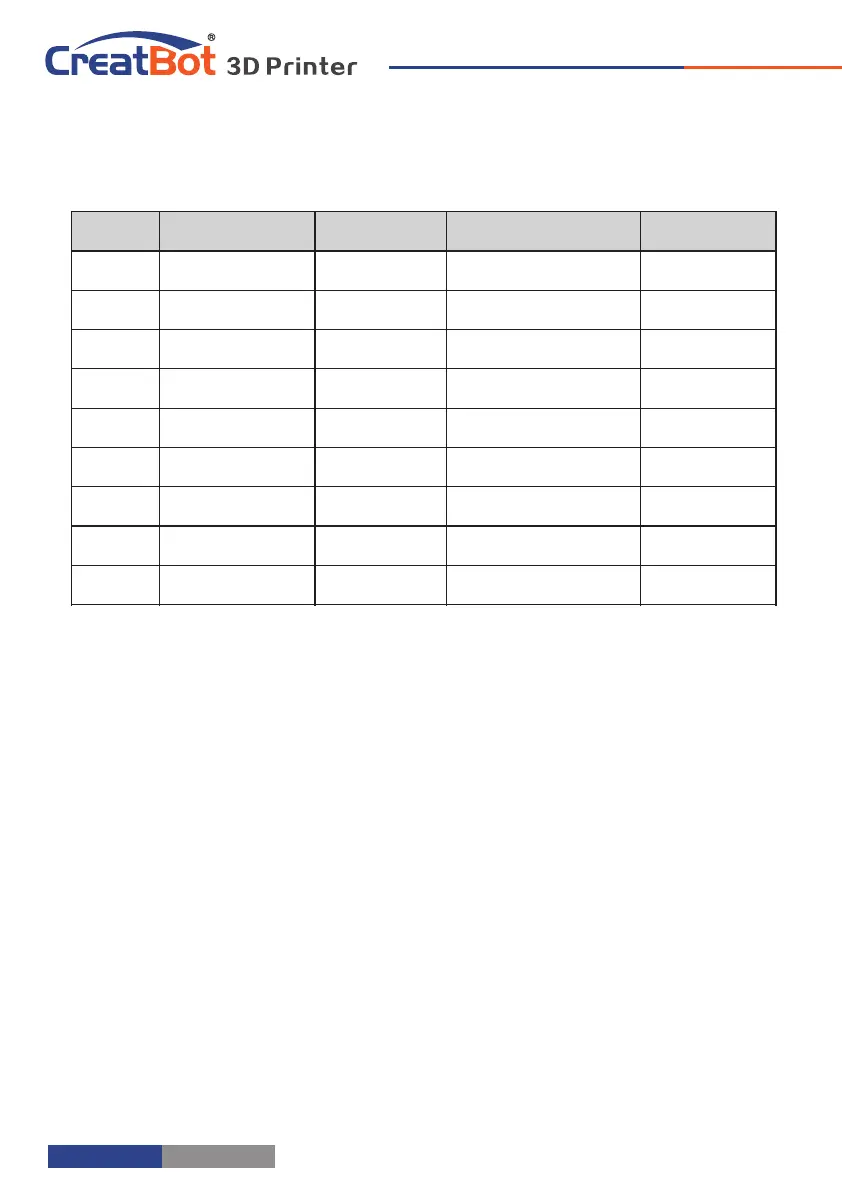

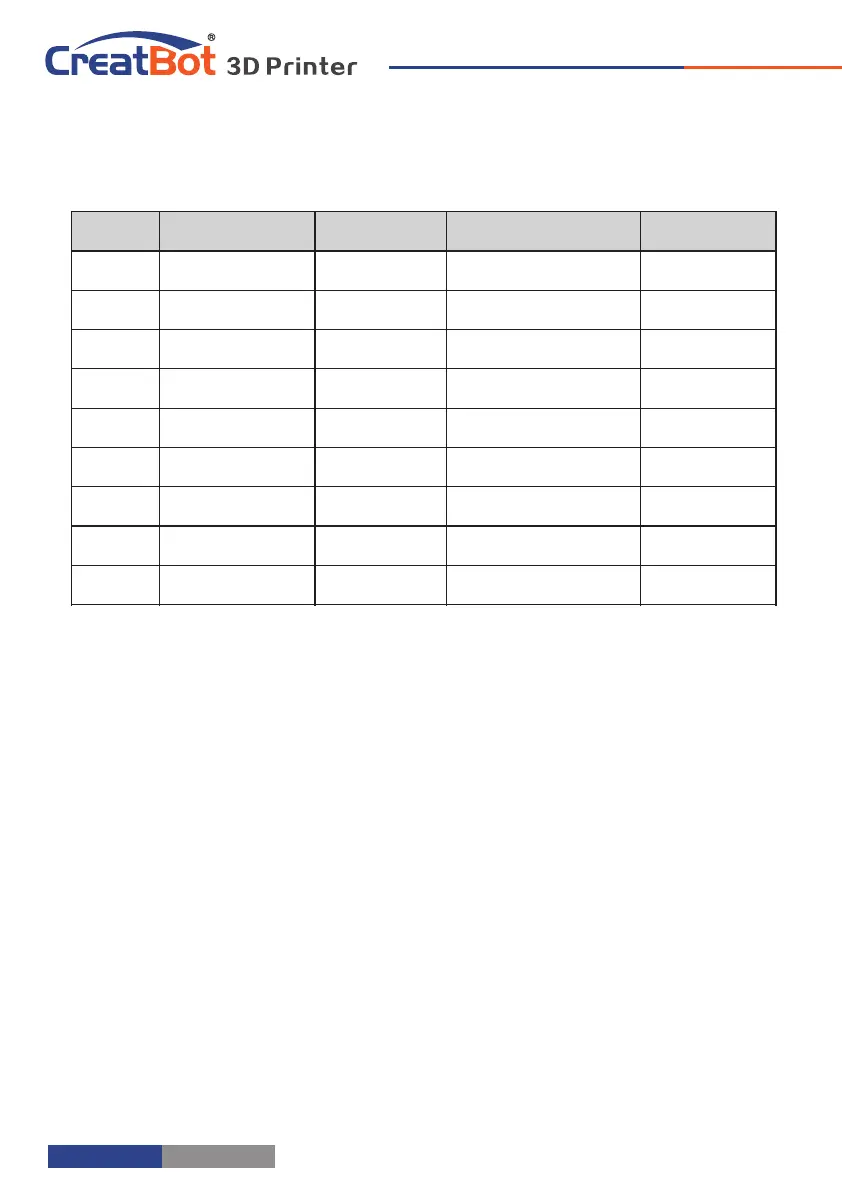

Print Setting Of Different Filament

* The data is only for reference, different environmental data will be different.F160 and F430 can print PEEK.

Software Opertation

- 35 -

Frequently Asked Questions

Hardware Troubleshoot

1. Display "MINTEMP" ?

The environment is too low, or temperature sensor is damaged, please keep

the room temperature above 0 ℃ .

2. Display "MAXTEMP" ?

Temperature of nozzle or bed too high, or temperature sensor is damaged,

please keep their temperature in a suitable range.

3. USB connection problems ?

Please specify the correct port and baud rate (250000), or change a shorter

USB cable.

4. Nozzle heats up too slowly ?

Temperature in door is too low, or use a fan duct, or turn up output voltage

(24.5v).

5. Print head stuck ?

Clean the guide rail and add lubricating oil.

6. Print head can not move ?

Stepper motor chipset burned, or belt damaged, or belt wheel screw loose.

7. Print head hit the framework ?

Corresponding axis stop limit or circuit fault.

8. Unable to power on ?

Power switch is damaged or fuse is burned, and please check whether the

power adapter is working properly or power check board is damaged.

Printing Troubleshoot

1. How to set the temperature of the nozzle ?

Different filament temperature is different, general as follows:

PLA temperature 190 ℃ ~210 ℃ ,bed 45-60 ℃ .

ABS temperature 230℃ ~250 ℃ ,bed 80-100 ℃ .

You must leave enough time for filament heating, so the faster printing speed

need the higher temperature, 60mm/s temperature need raise about 10℃. In

the same way, larger thickness need higher temperature.

2. How to set the temperature of the hot bed ?

The main purpose of the hot bed is to prevent model wrapped, PLA need

about 45℃ and 70℃ for ABS is enough, but due to the environment and

filament, we often need to increase the temperature, the highest temperature

Loading...

Loading...