LD 500_SHORT BAL_V2.03 EN Page 9 of 20

Surface leakage detection with the LD 500

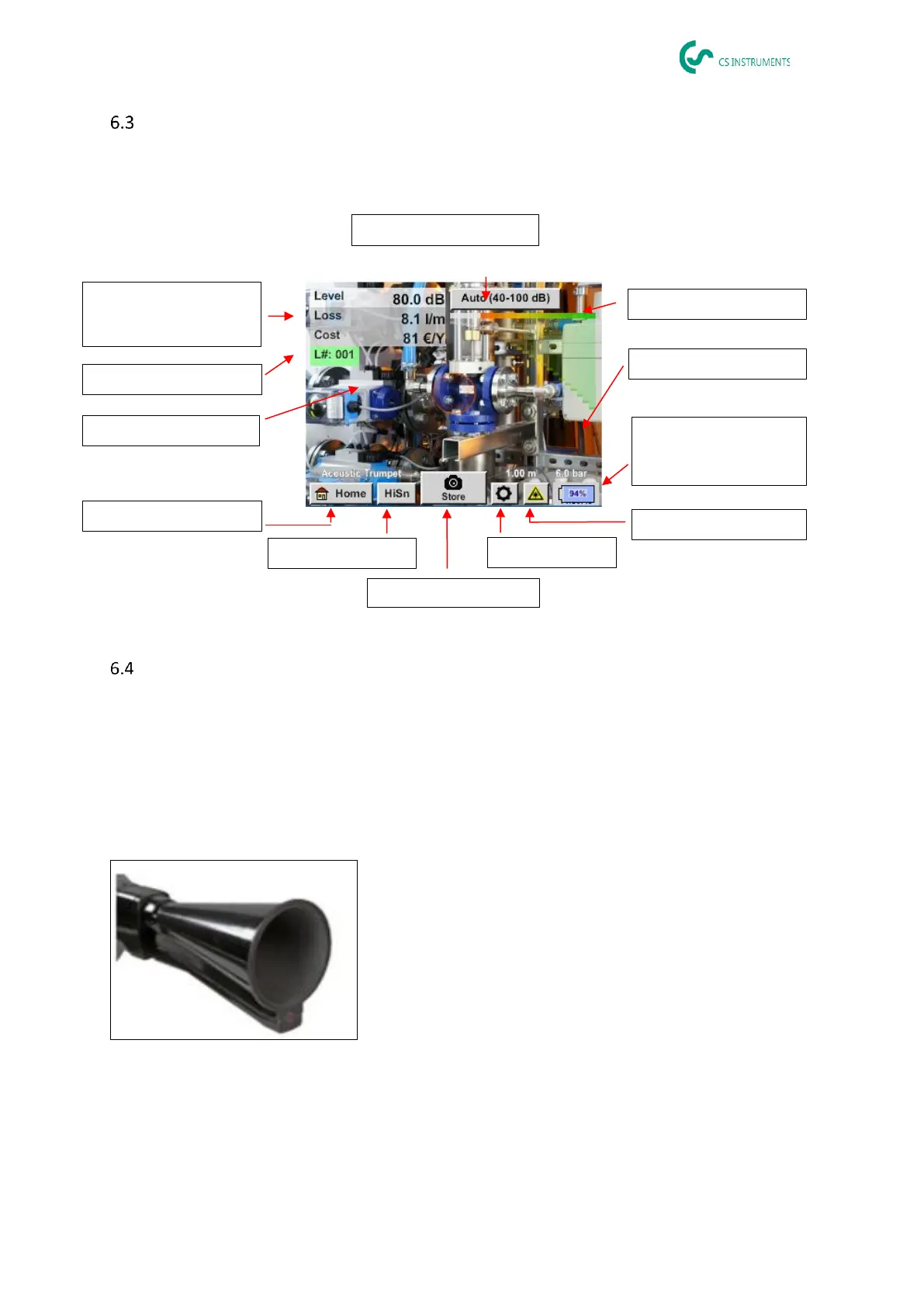

After start-up, the device shows the leakage detection view. The following figure lists the various

functions and displays.

Selection of accessories

To simplify leakage detection for the user, several attachments are available for different measuring

conditions.

Note on the distance setting for the quantification function:

The distances to be maintained for quantifying the leakage always refer to the front of the respective

attachment measured to the leakage.

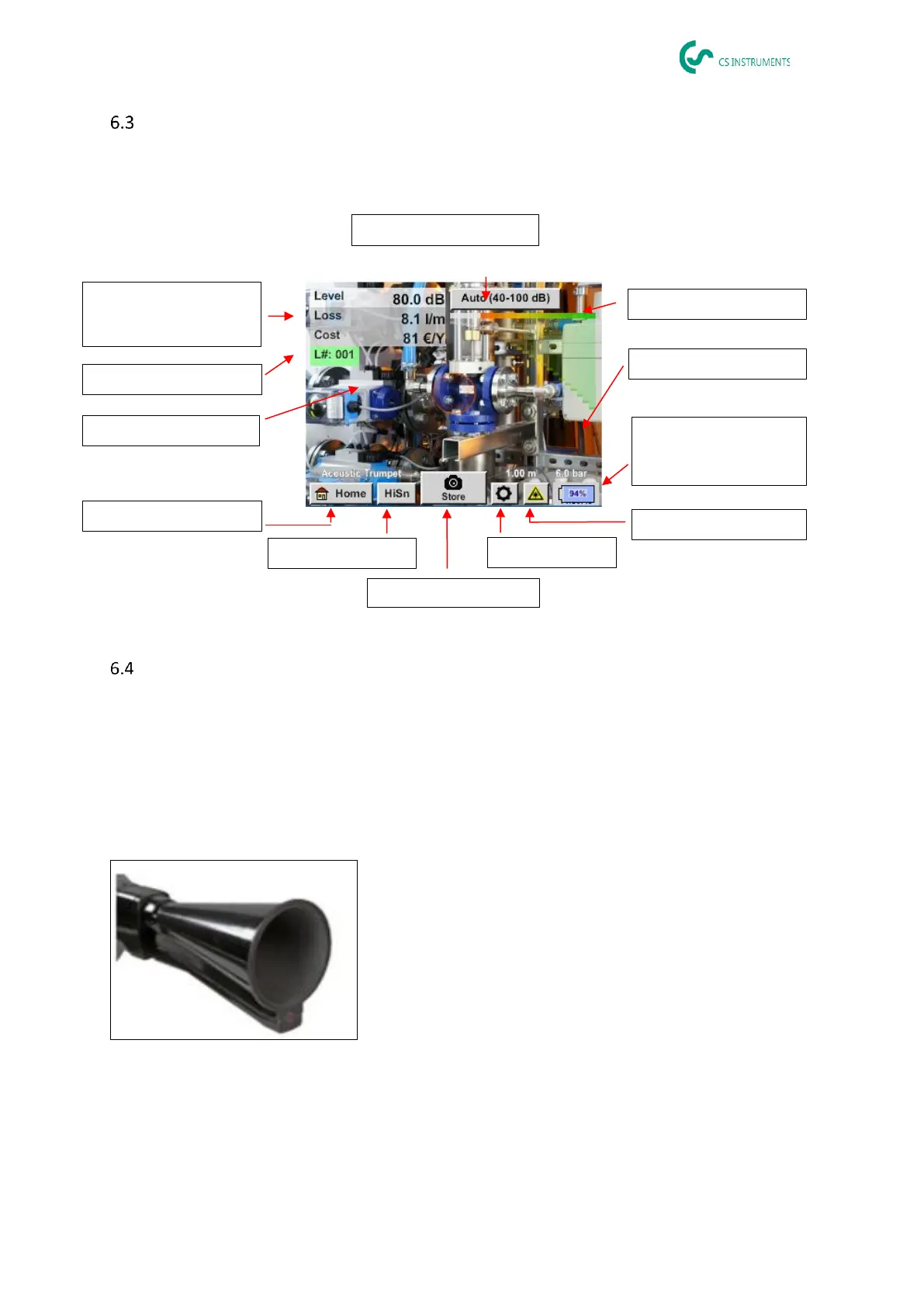

6.4.1 Acoustic trumpet (standard attachment)

The acoustic trumpet bundles incident ultrasonic waves,

thereby extending the range of the device. This behaviour

makes it ideal for medium distances.

The leakage can be heard from large distances, for precise de-

tection, the user must approach the leakage and consistently

follow the "loudest" point. Individual compressed air compo-

nents are then checked for precise detection.

Quantification distance (distance) → 1 – 6 m

Use of acoustic trumpet:

• Average distance to pipe/component 0.2 – 6 m

• Low interfering noise

• Leakage freely accessible

• Use at distances of up to 6 metres if no parabolic mirror available

Loading...

Loading...