25

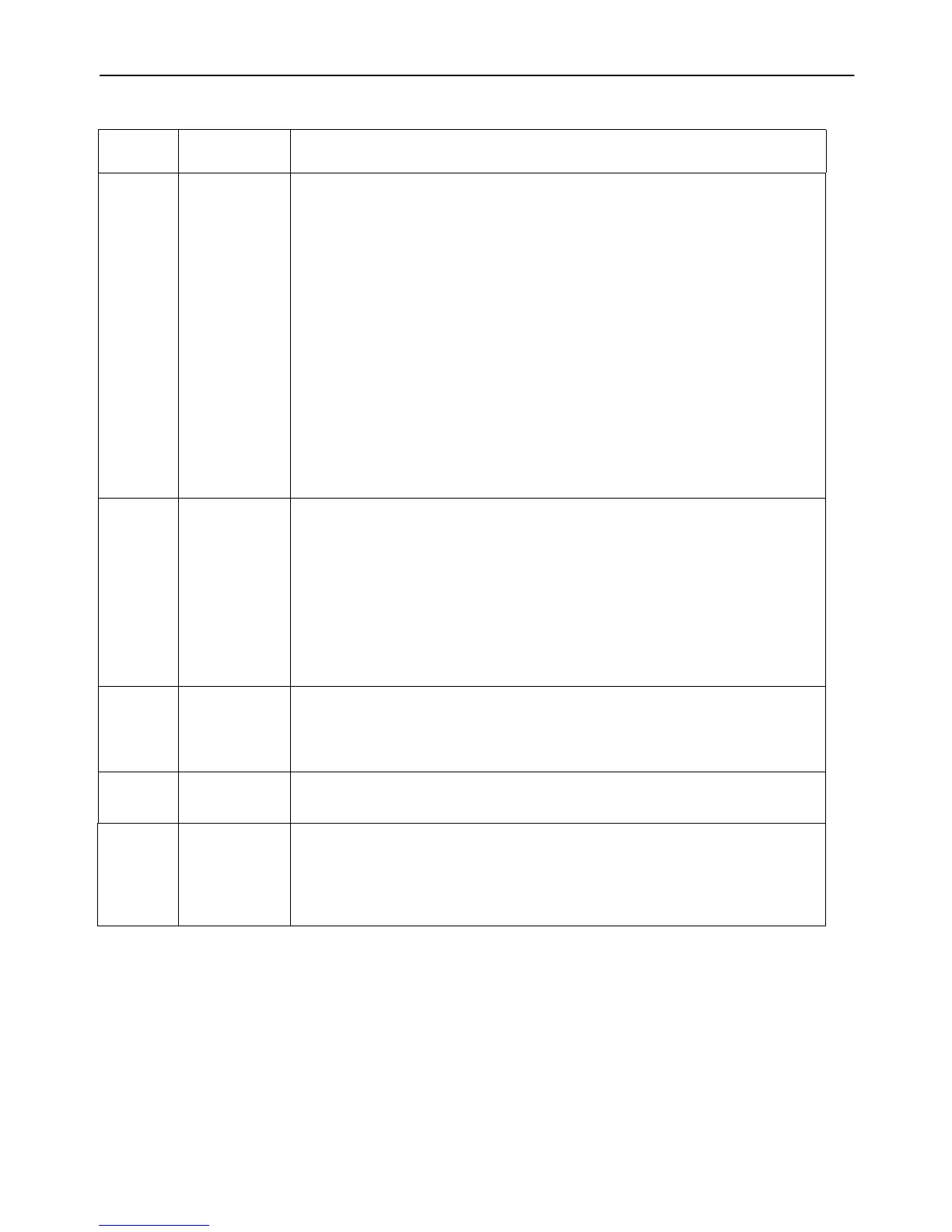

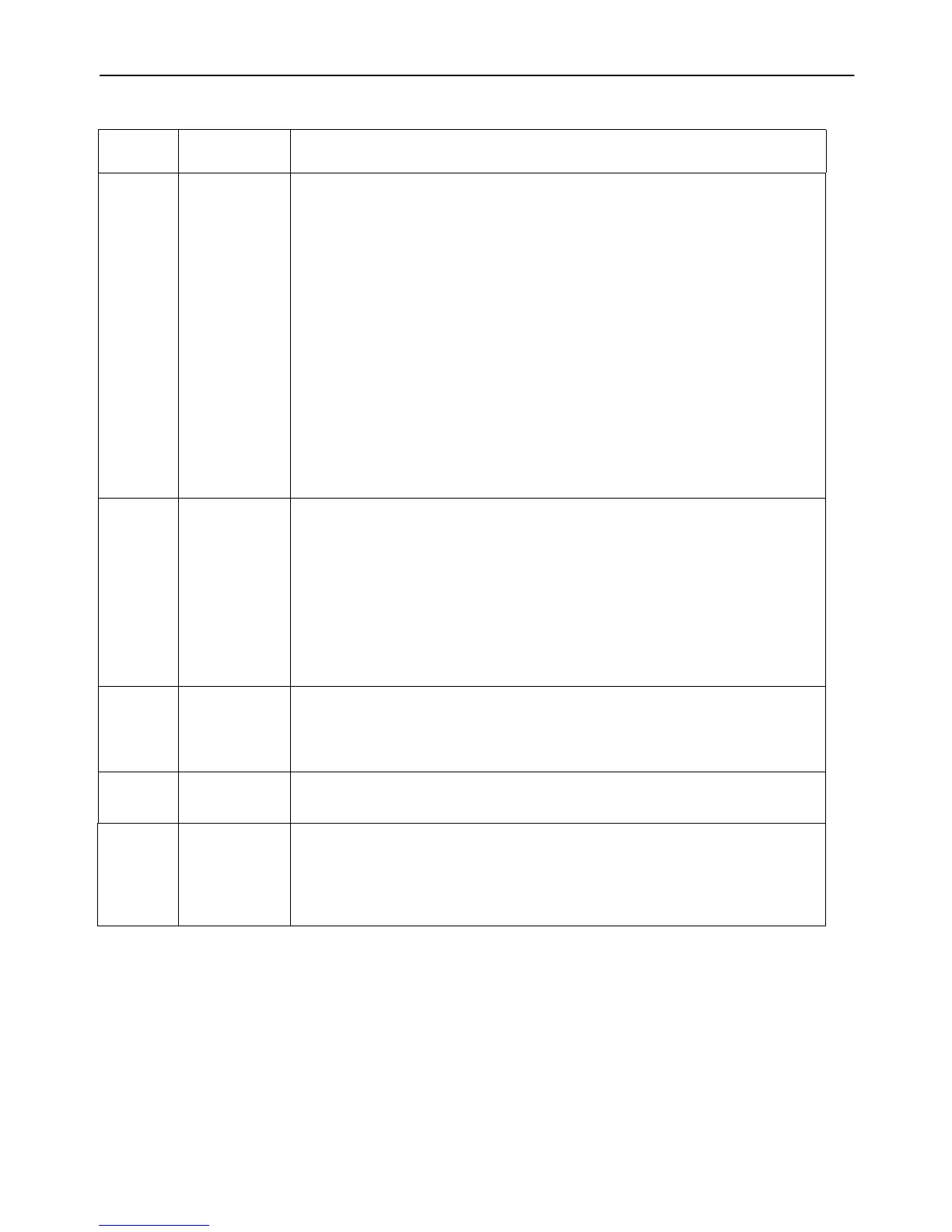

SECTION 12: TROUBLESHOOTING GUIDE

Trouble

Possible

Cause(s)

Corrective Action

Engine will

not crank

Safety switch

button not

depressed.

Battery installed

incorrectly.

Battery is dead

or weak.

Blown fuse

There are two safety switches in the starting circuit of your unit: the brake pedal switch

and the seat switch. Make certain the actuator is fully depressing the button on the

brake switch. The operator must be seated on the tractor in order to depress the seat

switch. The PTO knob must be in the disengaged (OFF) positio in order to start the

engine, also.

The battery must be installed with negative terminal attached to black ground wire.

Negative terminal is identified at the post by “NEG”, “N” or “-”. The positive terminal,

identified by “POS”, “P” or “+”, must be attached to the thick red wire which goes to the

solenoid.

Charge at six amps with a 12-volt automotive-type battery charger for one hour or until

fully charged.

Refer to operator’s manual for fuse location. Replace fuse with automotive type fuse of

the proper amperage. Fuses seldom fail without a reason. The problem must be

corrected. Check for loose connections in the fuse holder. Replace fuse holder if nec-

essary. A dead short may be in the cranking or charging circuit where the insulation

may have rubbed through and exposed the bare wire. Replace the wire or repair with

electrician's tape if the wire strands have not been damaged.

Note: Look for a wire pinched between body panels, burned by the exhaust pipe or

muffler or rubbed against a moving part.

Engine

cranks but

will not start

Throttle or choke

not in starting

position.

No fuel to the

carburetor.

No spark to

spark plug(s).

Dirty aircleaner.

Refer to the OPERATION section of this manual for the correct position of the throttle

control and choke for starting.

Gasoline tank empty. Fill.

Fuel line or in-line fuel filter plugged. Remove and clean fuel line. Replace fuel filter

(if so equipped) if necessary.

Spark plug lead disconnected. Connect lead. Using a spark tester, check for spark. If

no spark is present, have engine’s magneto serviced by an authorized engine dealer.

If the air cleaner is dirty, the engine may not start. Refer to the engine manual packed

with your unit.

Engine

smokes

Engine oil has

been overfilled.

Engine loses

crankcase

vacuum.

Check oil level.

Dipstick not seated or broken. Replace defective part.

Engine breather defective. Replace.

Excessive

vibration

Bent blade or

damaged pulley.

Stop engine immediately. Check all pulleys, blade adapters, keys and bolts for

tightness and spindle damage. Tighten or replace any loose or damaged parts.

Always replace damaged blade. Only use original equipment blades.

Mower

won’t

discharge

grass or

leaves

uncut strips

Engine speed

low.

Speed selection.

Cutting height

set too low.

Blades dull.

Throttle must be set at full throttle.

Use lower ground speed. The slower your ground speed, the better the quality of cut.

Raise deck.

Sharpen or replace blades (uncut strip problem only).

Loading...

Loading...