The cam stop may be adjusted to allow the imple-

ment to return to a single preset-height. See figure

11

With implement in desired height position,

release cam stop by turning locking knob counter-

clockwise. Turn cam stop until it contacts lift

bracket. Lock cam stop into this position by turn-

ing cam knob clockwise.

The fuel tank filler cap has an air vent. Keep

the vent open at all times to assure proper

flow of the fuel.

NOTE: Gasohol is not approved for use

by the engine manufacturer and

should not be used. The use of

gasohol may damage the engine.

FUEL SHUT-OFF VALVE

The fuel shut-off valve is located below the

gasoline tank.

To turn the fuel on, turn the knob counterclock-

wise to the stop.

To turn the fuel off, turn the knob clockwise until

it is tight.

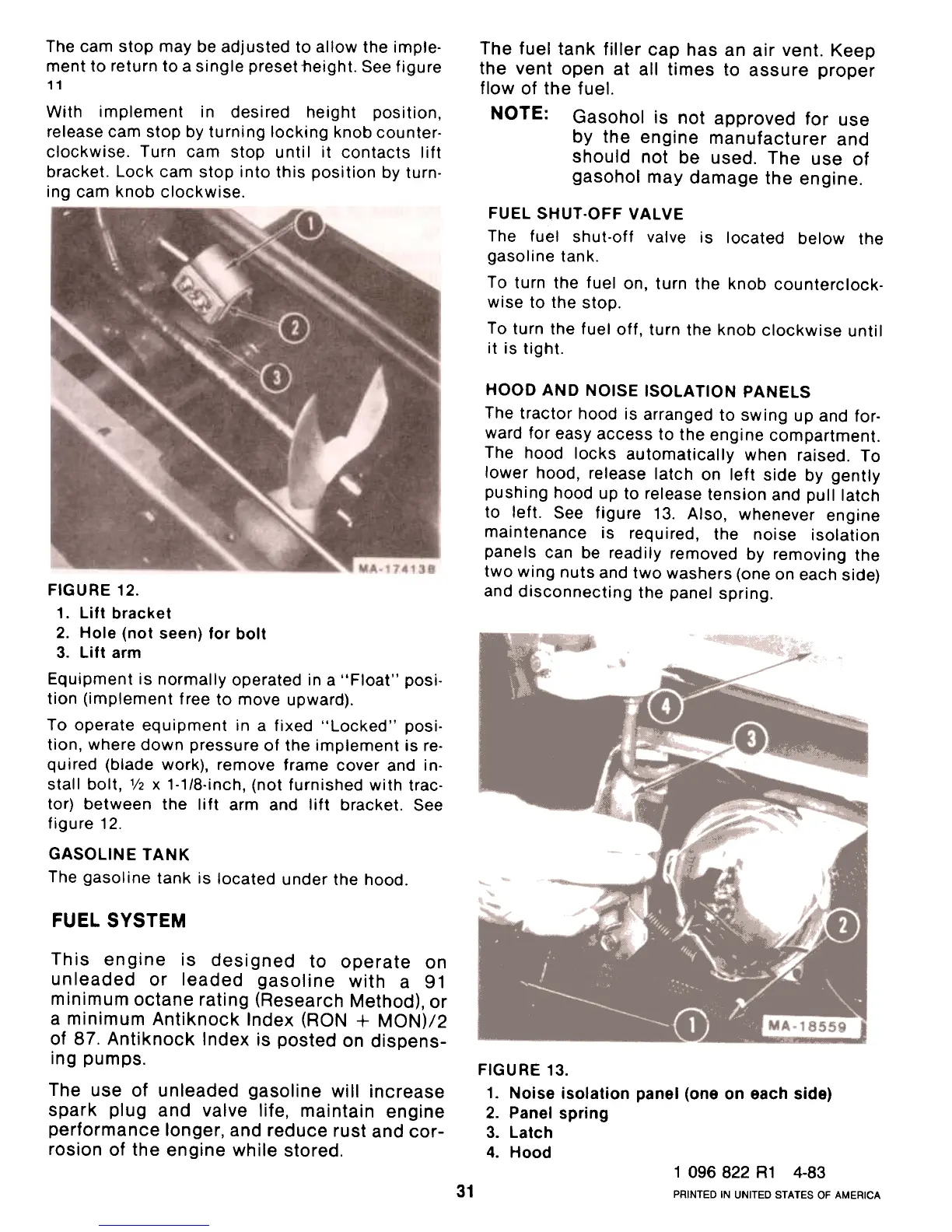

HOOD AND NOISE ISOLATION PANELS

The tractor hood is arranged to swing up and for-

ward for easy access to the engine compartment.

The hood locks automatically when raised. To

lower hood, release latch on left side by gently

pushing hood up to release tension and pull latch

to left. See figure 13. Also, whenever engine

maintenance is required, the noise isolation

panels can be readily removed by removing the

two wing nuts and two washers (one on each side)

and disconnecting the panel spring.

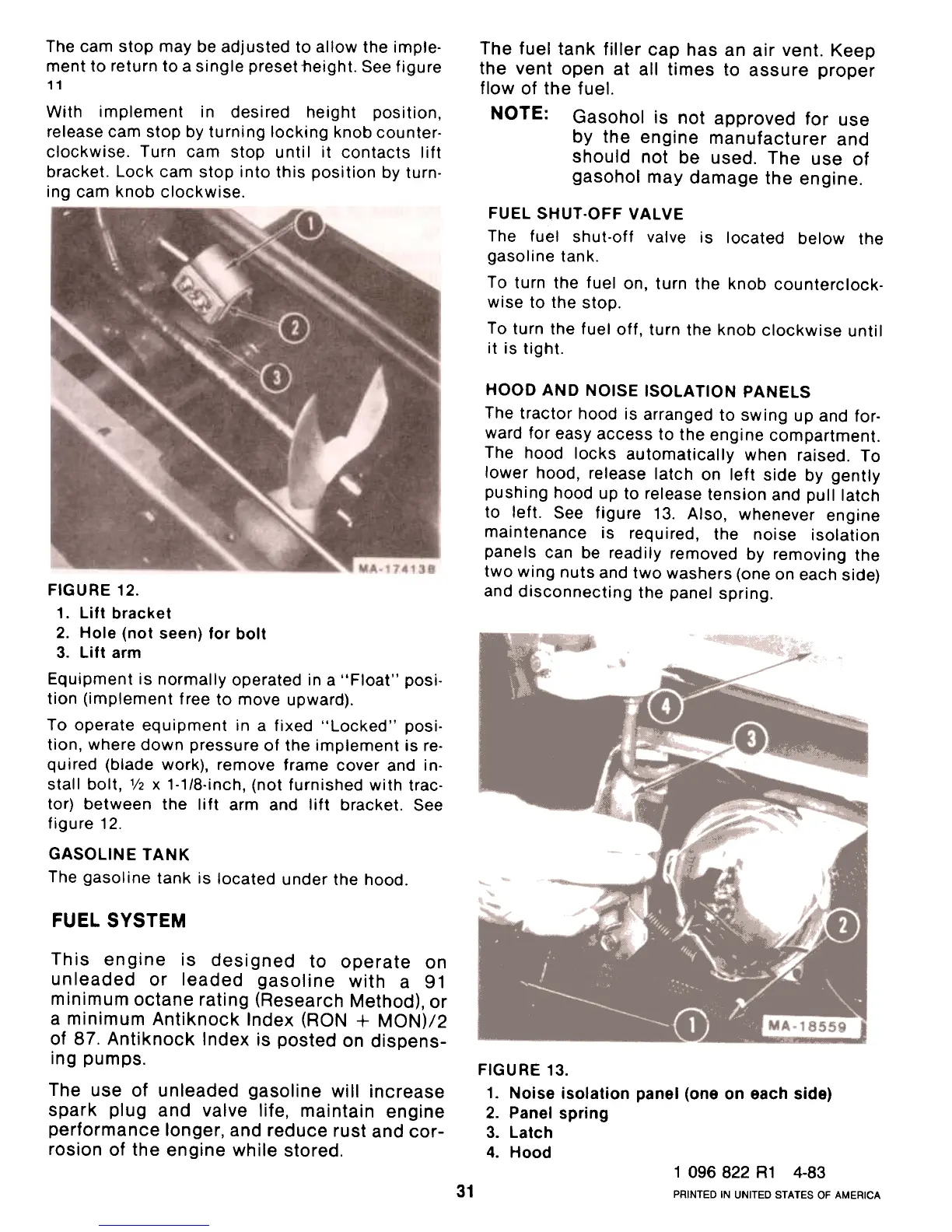

FIGURE 12.

1. Lift bracket

2. Hole (not seen) for bolt

3. Lift arm

Equipment is normally operated in a "Float" posi-

tion (implement free to move upward).To

operate equipment in a fixed "Locked" posi-tion,

where down pressure of the implement is re-

quired (blade work), remove frame cover and in-

stall bolt, 1/2 x 1-1/8-inch, (not furnished with trac-

tor) between the lift arm and lift bracket. See

figure 12.

GASOLINE TANK

The gasoline tank is located under the hood.

FUEL SYSTEM

This engine is designed to operate on

unleaded or leaded gasoline with a 91

minimum octane rating (Research Method), or

a minimum Antiknock Index (RON + MON)/2

of 87. Antiknock Index is posted on dispens-

ing pumps.

The use of unleaded gasoline will increase

spark plug and valve life, maintain engine

performance longer, and reduce rust and cor-

rosion of the engine while stored.

FIGURE 13.

1. Noise isolation panel (one on each side)

2. Panel spring

3. Latch

4. Hood

1 096 822 R1 4-83

PRINTED IN UNITED STATES OF AMERICA

31

Loading...

Loading...