Engine

4‐45

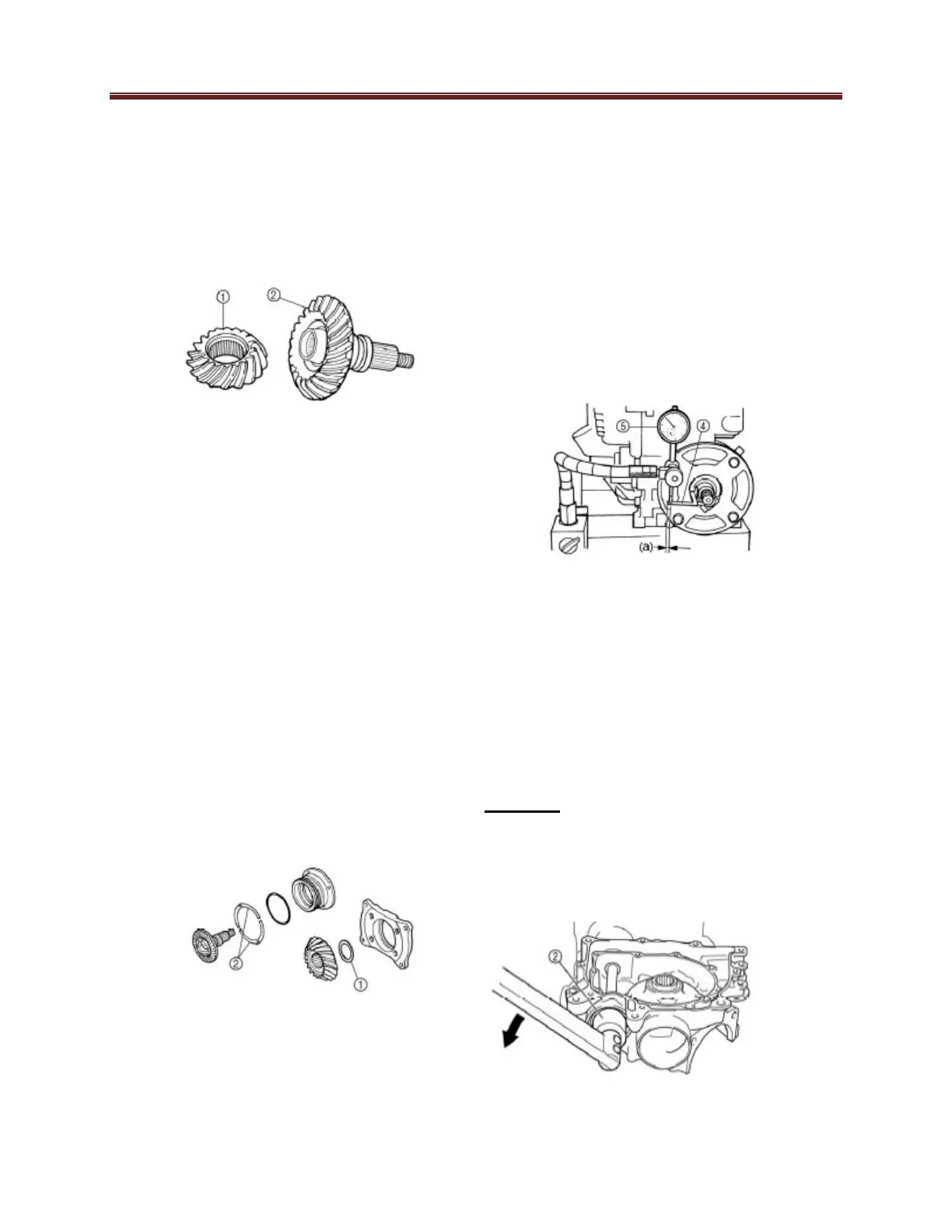

Inspect the pinion gears

Drive pinion gear (1)

Driven pinion gear (2)

Look at the teeth for pitting, galling

or wear

O-ring

Replace

Bearings

Look for pitting or damage.

Universal joint movement

Look for smooth movement.

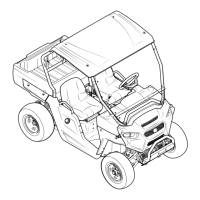

Selecting the middle drive and driven gear

shims.

Check gear lash

Middle drive gear shim (1)

Middle driven gear shim (2)

Middle gear lash: 0.1 - 0.3 mm

Measure gear lash

Temporarily install the left

crankcase half.

Wrap a rag around a screwdriver

and insert it into the right crankcase

speed sensor hole to hold the

middle driven gear.

Attach a dial gauge.

6.7mm or 0.26 in

Measure at four points rotating 90

degrees each time.

If gear lash is incorrect, adjust by

changing the shims.

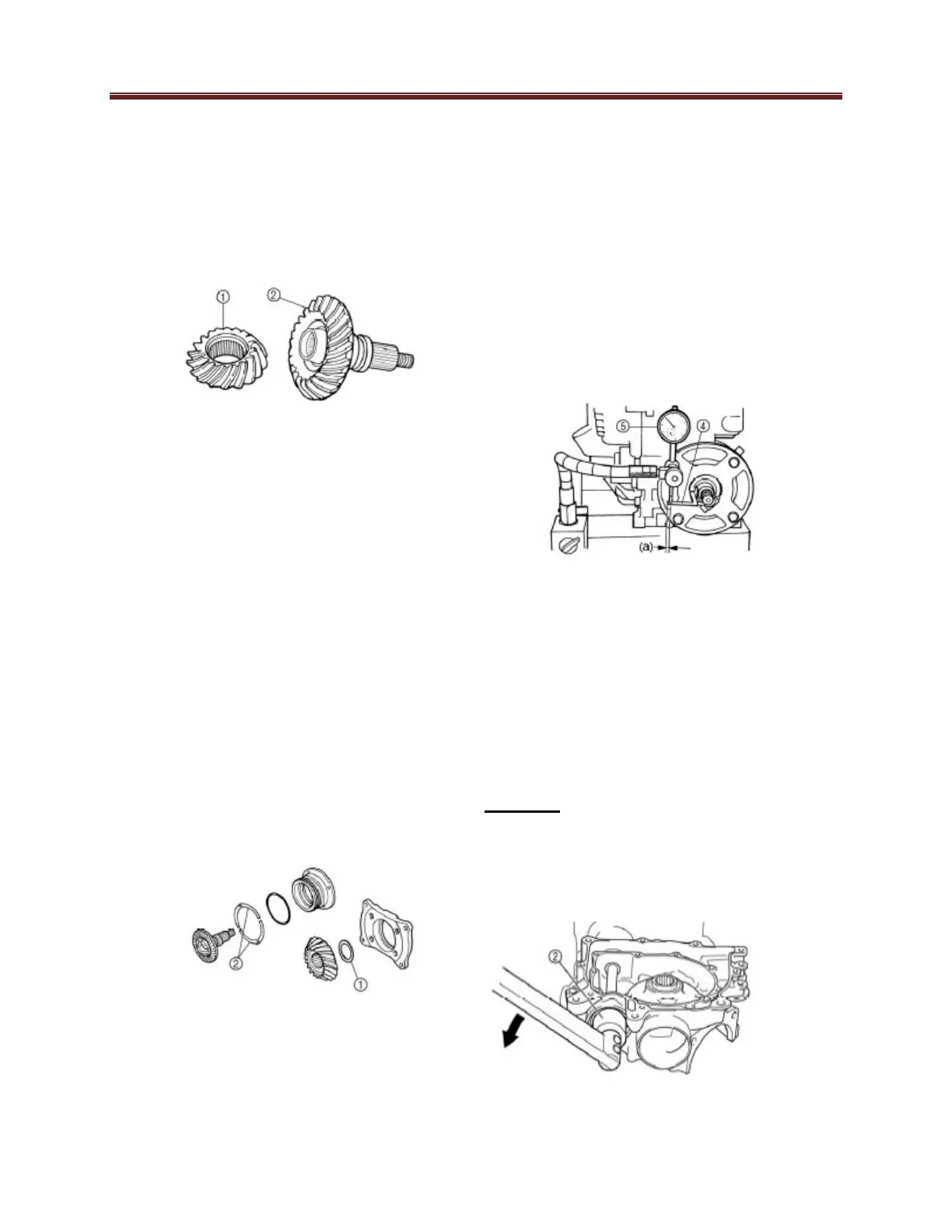

Installing the middle driven shaft

Bearing retainer (1)

Bearing retainer 80 Nm or 59 ft lbs

Attach the socket wrench (2)

Caution:

The middle driven shaft bearing

retainer has left handed threads, to

tighten, turn it counterclockwise.

Loading...

Loading...