Chassis

5‐38

3.

Inspect the balls and ball races.

Look for pitting, wear or damage.

Check that the movement of the

joint is

smooth in all directions, in,

out

and around.

4.

All components should be cleaned

before assembly.

Do not use chemicals on the dust boots,

for cleaning use only hot soapy water.

When reassembling the balls and ball

cage fill with approximately 2/3 volume of

lithium grease.

Inspecting the Differential Gear

1.

Inspect gear teeth.

Look for pitting, galling or wear.

2.

Inspect the bearings.

Look for pitting or damage.

3.

Inspect the oil seals and O-rings.

Look for damage.

4.

Inspect the drive shaft splines,

universal joints and the drive pinion

gear splines.

Look for wear or damage.

5.

Inspect the spring.

Look for fatigue.

6.

Inspect the front drive shaft.

Look for bends.

7.

Inspect the torque limiter.

Look for looseness.

Before assembly,

Apply lithium grease to the oil s

eal, front

box output shaft and oil seal, front input

shaft and differential gear assembly.

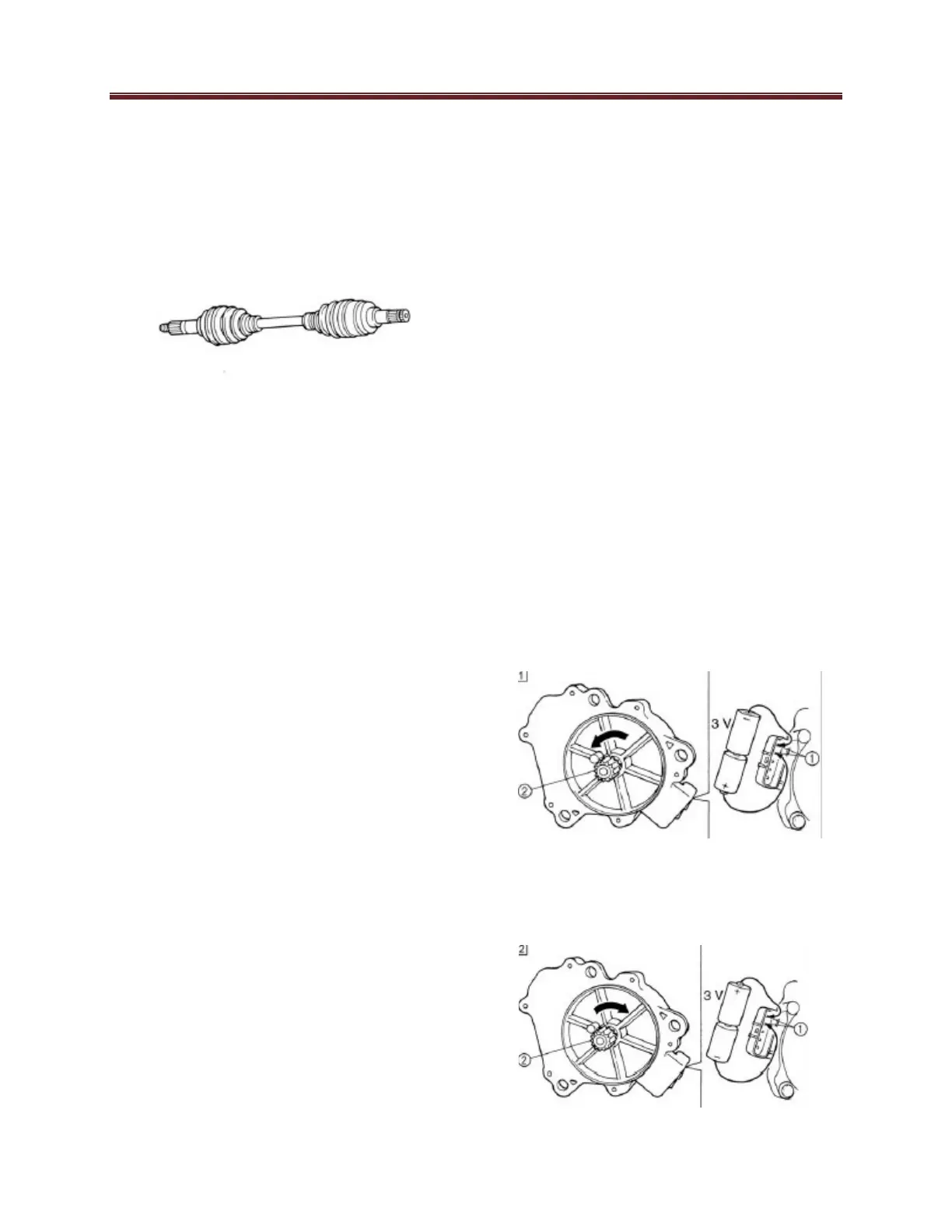

Checking the Operation of the Gear

Motor

1.

Remove the gear motor from the

case.

2.

Connect two C size batteries to the

gear motor terminals (1).

Do not use 12V battery to check

the motor.

Check that the motor turns

counterclockwise. (1)

Check that the motor turns

clockwise. (2)

Loading...

Loading...