28 se c t i O n 6— Ma i n t e n a n c e & ad j u s t M e n t s

Fuel System

fuel tank and fuel pump. It should be inspected daily and

purged of any contaminents.

2.

type.

The Main Fuel Filter is a spin-on cartridge.

Air Cleaner

Hydraulic Oil

WARNING! Never overfill the hydraulic units.

Damage can occur if the oil level is not within the

proper operating range.

NOTE: When adding hydraulic oil, do so in small quantities and

recheck the oil level before adding more. It is important that you

do not overfill the reservoir.

Battery Maintenance

The battery is filled with battery acid and then sealed at

fill caps and check the level of the liquid electrolyte in the

battery. If the level in any of the six cells has dropped below

the bottom of the split ring inside the fill hole, refill the cell

with distilled water.

terminal sealer, or coat the terminals with a thin coat of

grease or petroleum jelly, to protect against corrosion.

Always keep the battery cables and terminals clean and

free of corrosion.

Avoid tipping. Even a sealed battery will leak electrolyte

when tipped.

WARNING!

emit explosive gases. Use extreme caution when

handling batteries. Keep batteries out of the reach

of children.

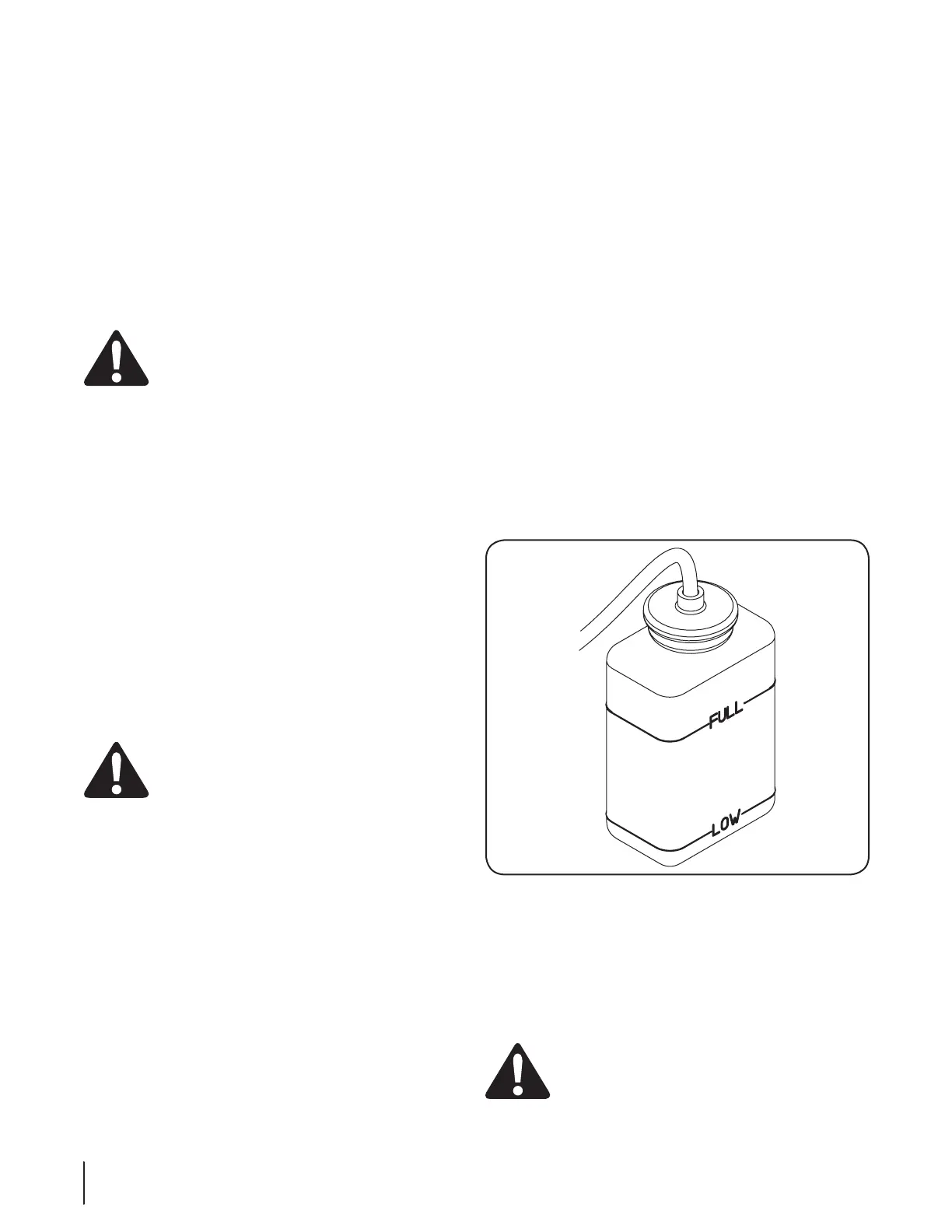

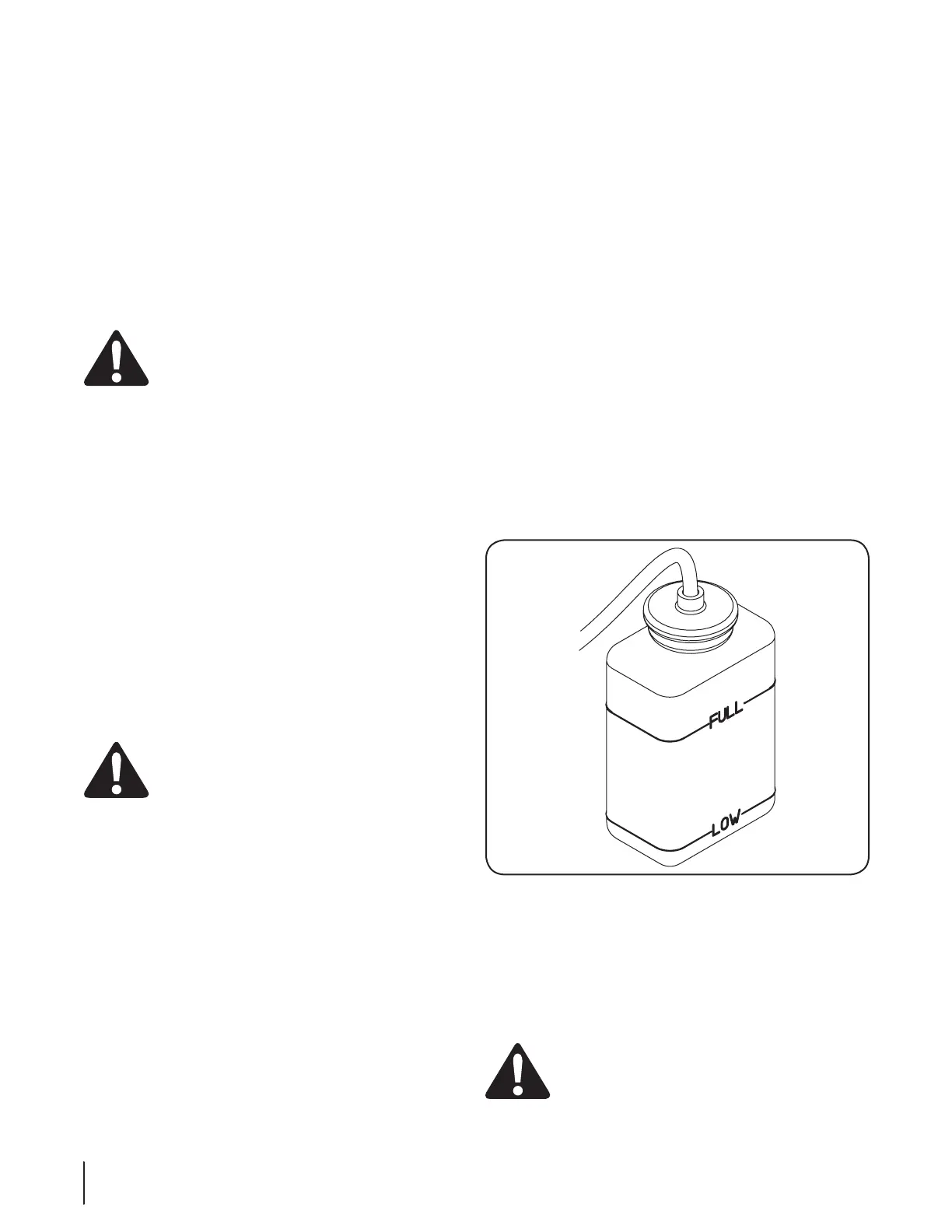

Engine Coolant

Checking Engine Coolant Level

reservoir should be checked to ensure it is within the operating

range. Engine coolant absorbs heat from the engine and

transfers the heat to the air flowing through the radiator. If the

coolant level becomes low, the engine may overheat and could

cause severe damage to the engine.

Use a permanent type antifreeze containing corrosion and rust

NOTE: Distilled water is recommended for the coolant solution

IF your tap water has a high mineral content. Minerals cause

efficiency will be greatly reduced over time and severe engine

instructions for additional information on dilution procedures.

Check the coolant level when the engine is cold and the

tractor is on a level surface.

Check the coolant level in the overflow reservoir on the 2.

right side of the tractor.

cap from the reservoir and add coolant solution to the

“FULL” mark. Refer to Fig. 6-2.

NOTE: The cooling system is a closed type. Normally, to prevent

air from entering the system, the radiator cap should not be

removed.

If the overflow reservoir is empty, the radiator cap should be

removed and the coolant level in the radiator checked before

adding coolant to the reservoir. If necessary, first refill the system

through the radiator filler neck as follows:

WARNING! It is dangerous to remove the radiator

cap when the system is hot. Allow the system to cool

before removing the radiator cap.

Figure 6-2

Loading...

Loading...