Page 34 40 Series Granulators

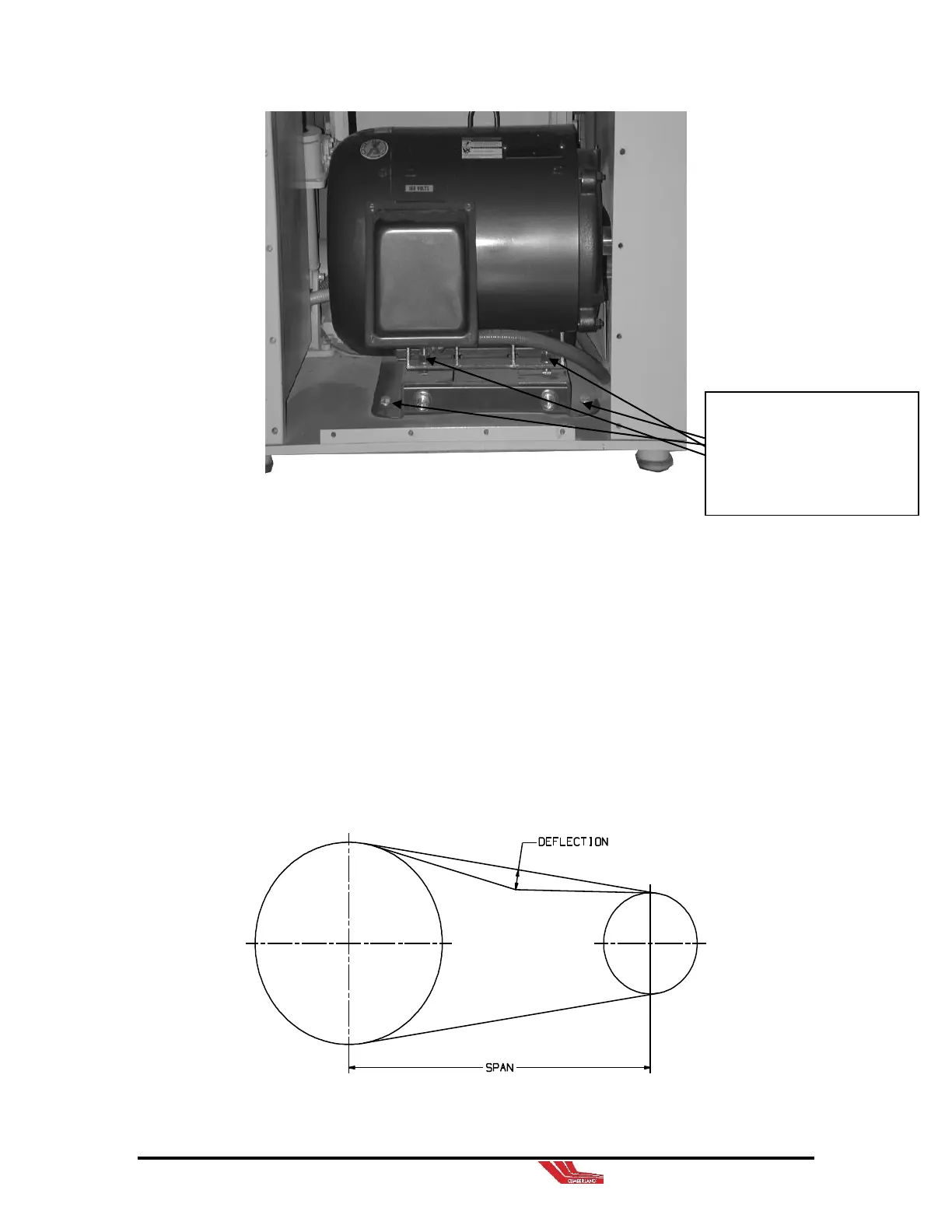

5. There will normally be a drop in belt tension during the

first 24 to 48 hours of operation due to stretch and the

belts seating themselves in the sheave grooves.

6. After this initial “RUN IN” period, the machine should

be stopped and the belts should be re-checked for

tension. The motor position should be adjusted until

the deflection matches the force required.

7. In no case should the belts be over-tensioned as this can

significantly reduce belt and/or bearing life.

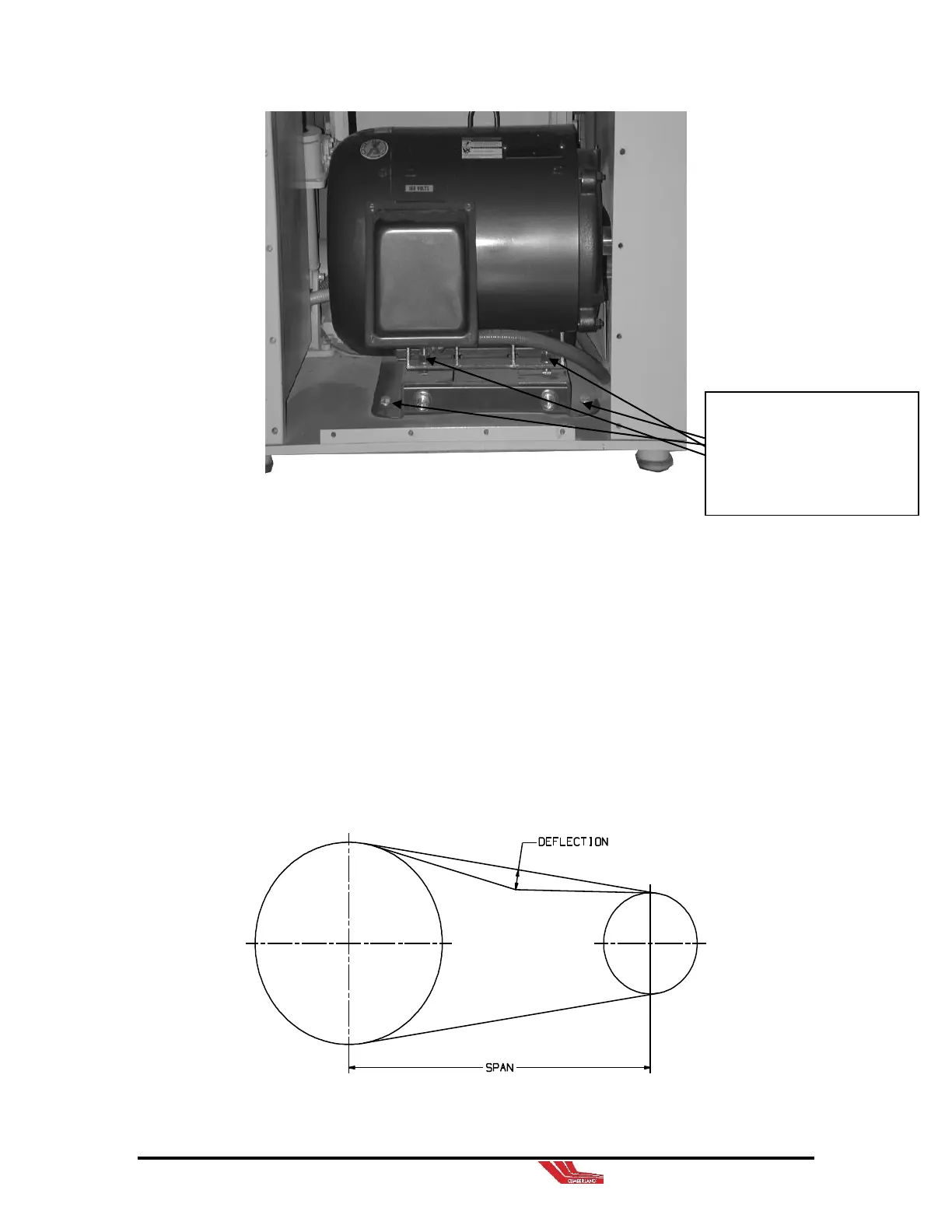

Figure 2

Belt Span and Deflection

Loosen these 4 nuts on the

bolts holding the unit on the

base. Slide the motor either

backwards or forwards to

achieve the proper belt

tension and retighten the nuts.

Loading...

Loading...