ENGINE

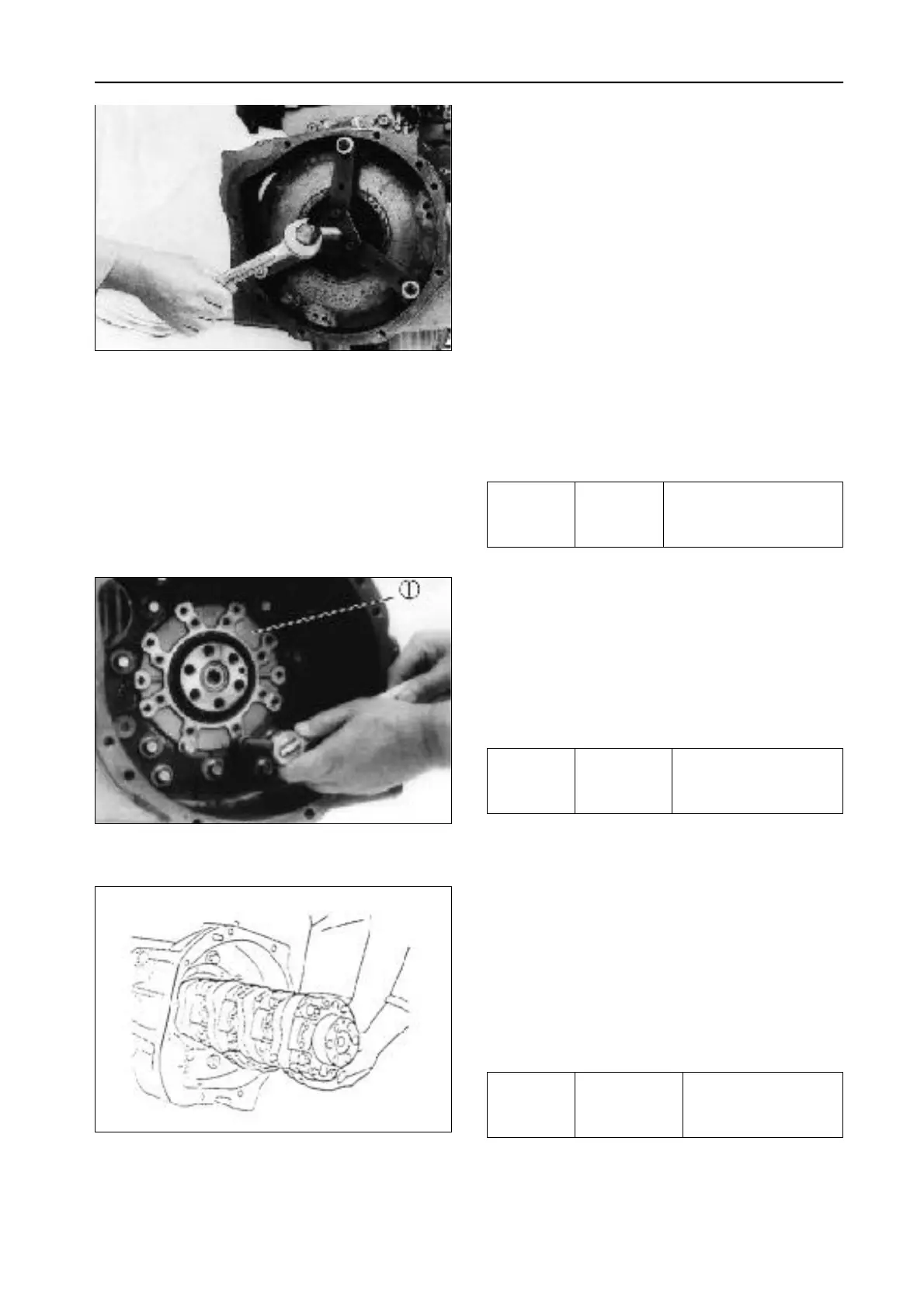

4) Crankshaft

(A) Flywheel

1. Install the stopper to the flywheel and loosen the

s c r e w.

2. Remove the flywheel stopper and the flywheel.

(When reassembling)

• Clean the end of crankshaft and the mating surface

of the flywheel.

• Apply oil to flywheel screws.

• Fit the flywheel hole to crankshaft hole and tighten

the flywheel bolts to specified torque.

NOTE :

• Screw longer screws to the flywheel to carry it, if

n e e d e d .

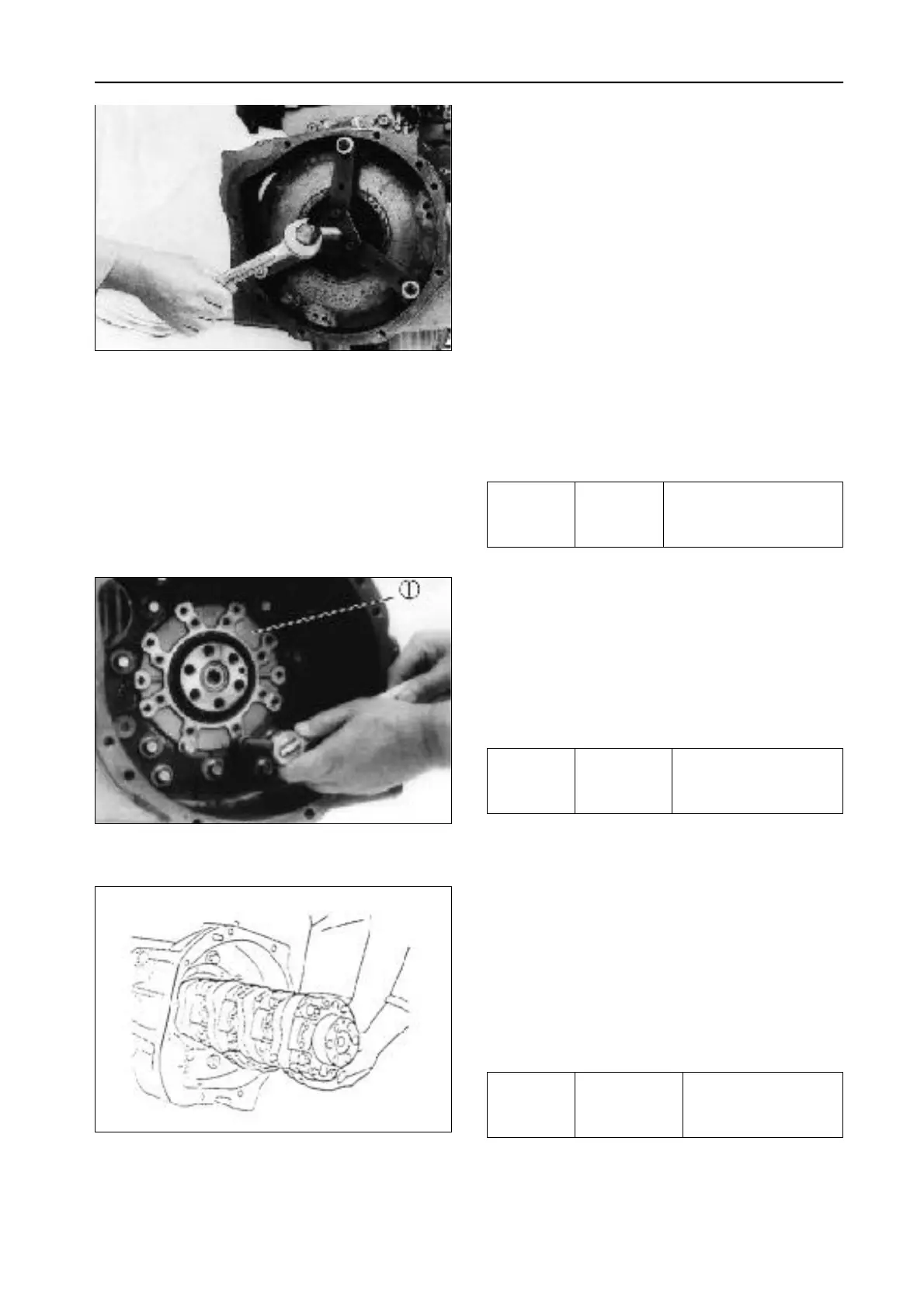

(B) Bearing Case Cover

loosen the screw first inside and next outside, and lift

the cover (1) by screwing two screws gradually and

e v e n l y, refering to the photo.

(When reassembling)

• Apply grease to the oil seal lip and take care that it

is not rolled when installing.

(1) Bearing Case cover

(C) Crankshaft

1. Remove the main bearing case screw 2.

2. Pull out the crankshaft, taking care not to damage

the crankshaft bearing 1.

(When reassembling)

• Apply oil to the bearing case screw.

• Clean the oil passage of the crankshaft with

compressed air.

10.0 to 11.0kgf•m

Tightening Flywheel

98.1 to 107.9N•m

torque screw

72.3 to 79.6ft-lbs

2.4 to 2.8kgf• m

Tightening Bearing case

23.5 to 27.5N• m

torque cover screw

17.4 to 20.3ft-lbs

7.0 to 7.5kgf• m

Tightening Main bearing

68.7 to 73.6N• m

torque case screw 2

50.6 to 54.2ft-lbs

Loading...

Loading...