29

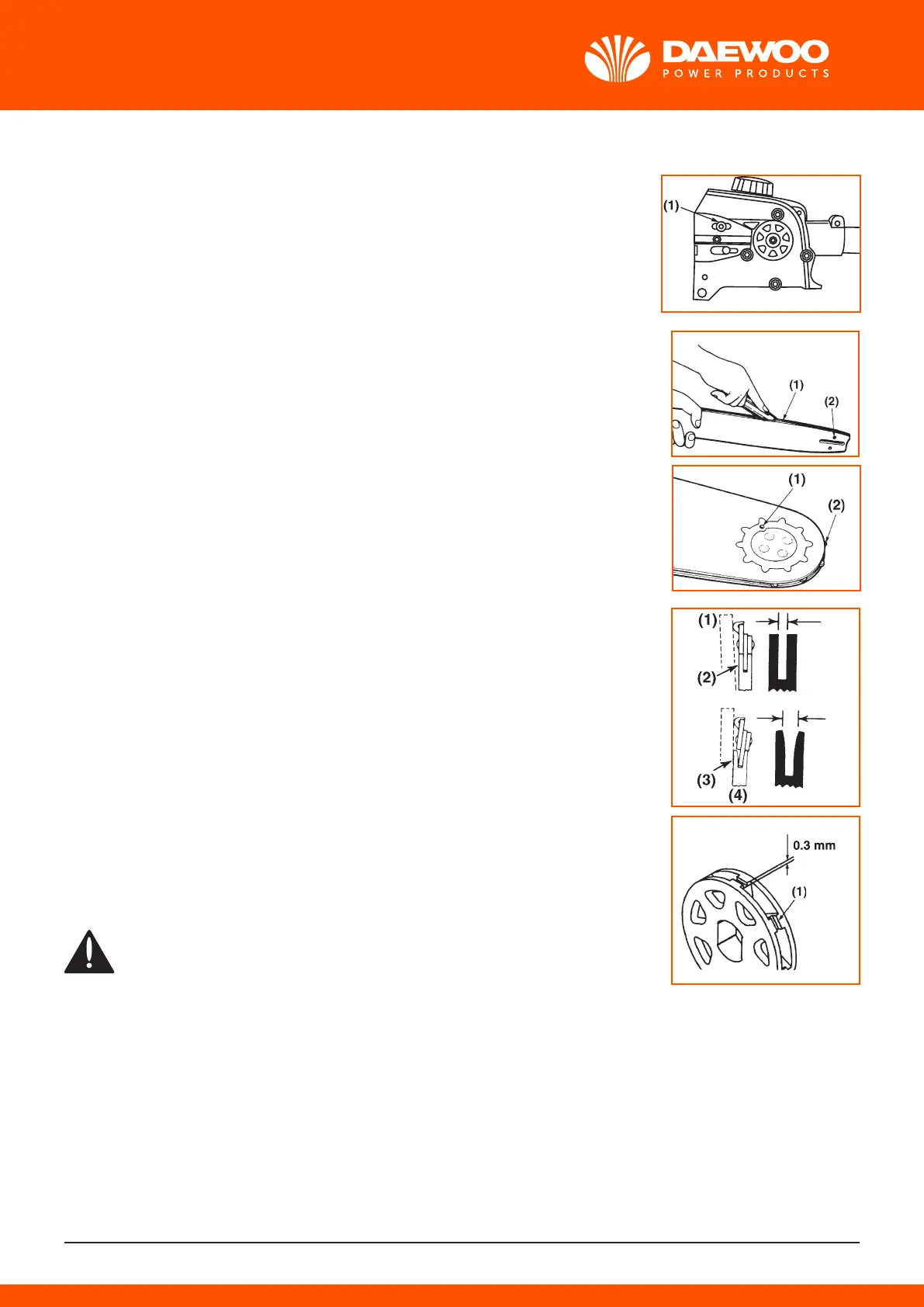

OILING PORT

Dismount the guide bar and check the oiling port for clogging.

(1) Oiling port

GUIDE BAR

Remove sawdust in the bar groove and the oiling port.

(1) Groove

(2) Oiling port

(Type: Sprocket nose)

Grease the nose sprocket from the feeding port on the tip of the bar.

(1) Grease port

(2) Sprocket

The bar rail should always be a square. Check for wear of the bar rail. Apply

a ruler to the bar and the outside of a cutter. 11 a gap is observed between

them, the rail is normal. Otherwise, the bar rail is worn. Such a bar needs to

be corrected or replaced.

(1) Ruler

(2) Gap

(3) No gap

(4) Chain lilts

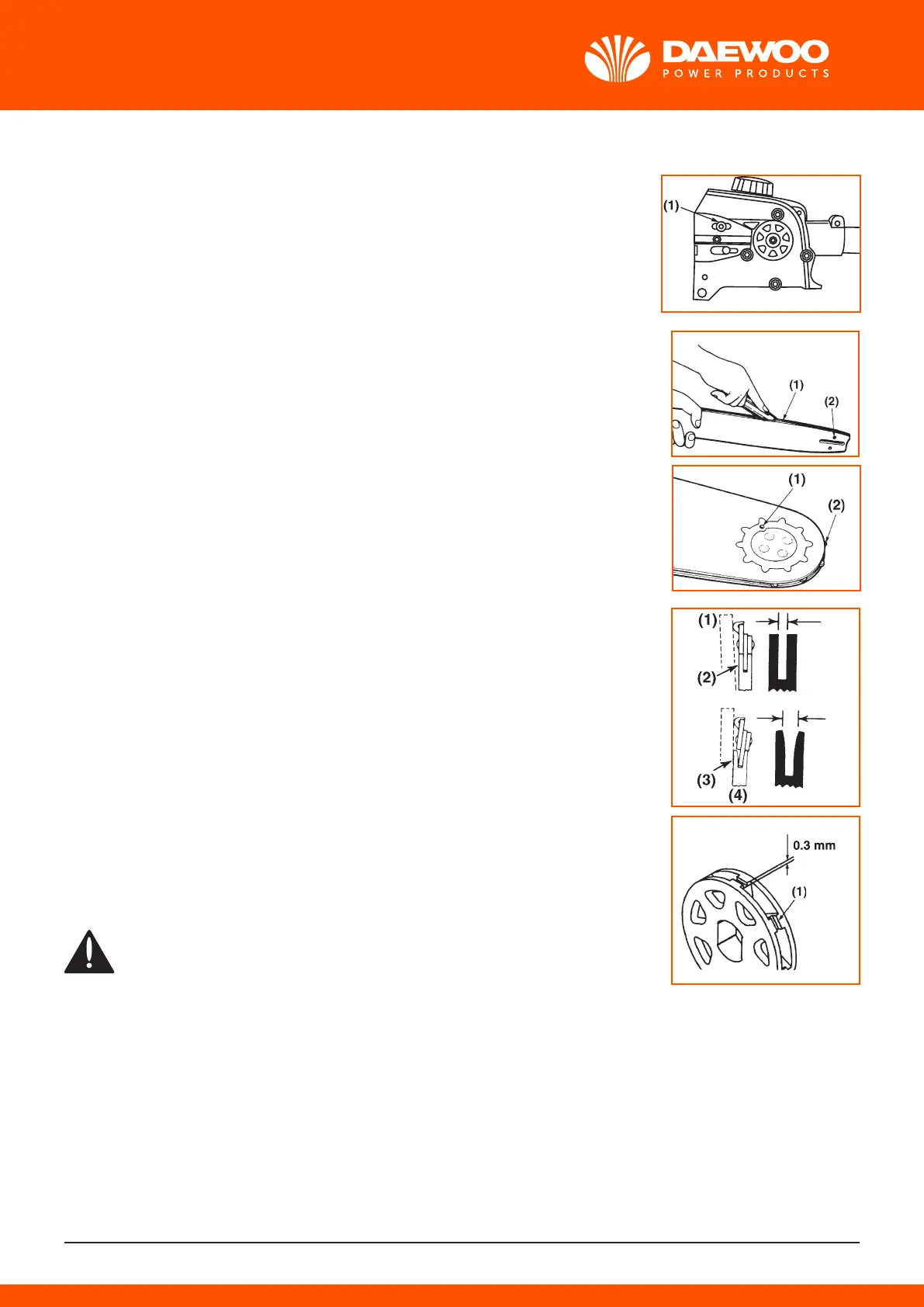

SPROCKET

Check for extensive wear, and replace it when the teeth are worn over

0.3 mm.

(1) Sprocket

SAWCHAIN

WARNING

lt is very important for smooth and safe operation to a keep the cutters

alwys sharp.

Your cutters need to be sharpened when:

Sawdust becomes powder-like.

ou need extra force to saw in. The cut way does not go straight.

Vibration increases.

Fuel consumption increases.

Cutter setting standards:

Loading...

Loading...