43 44

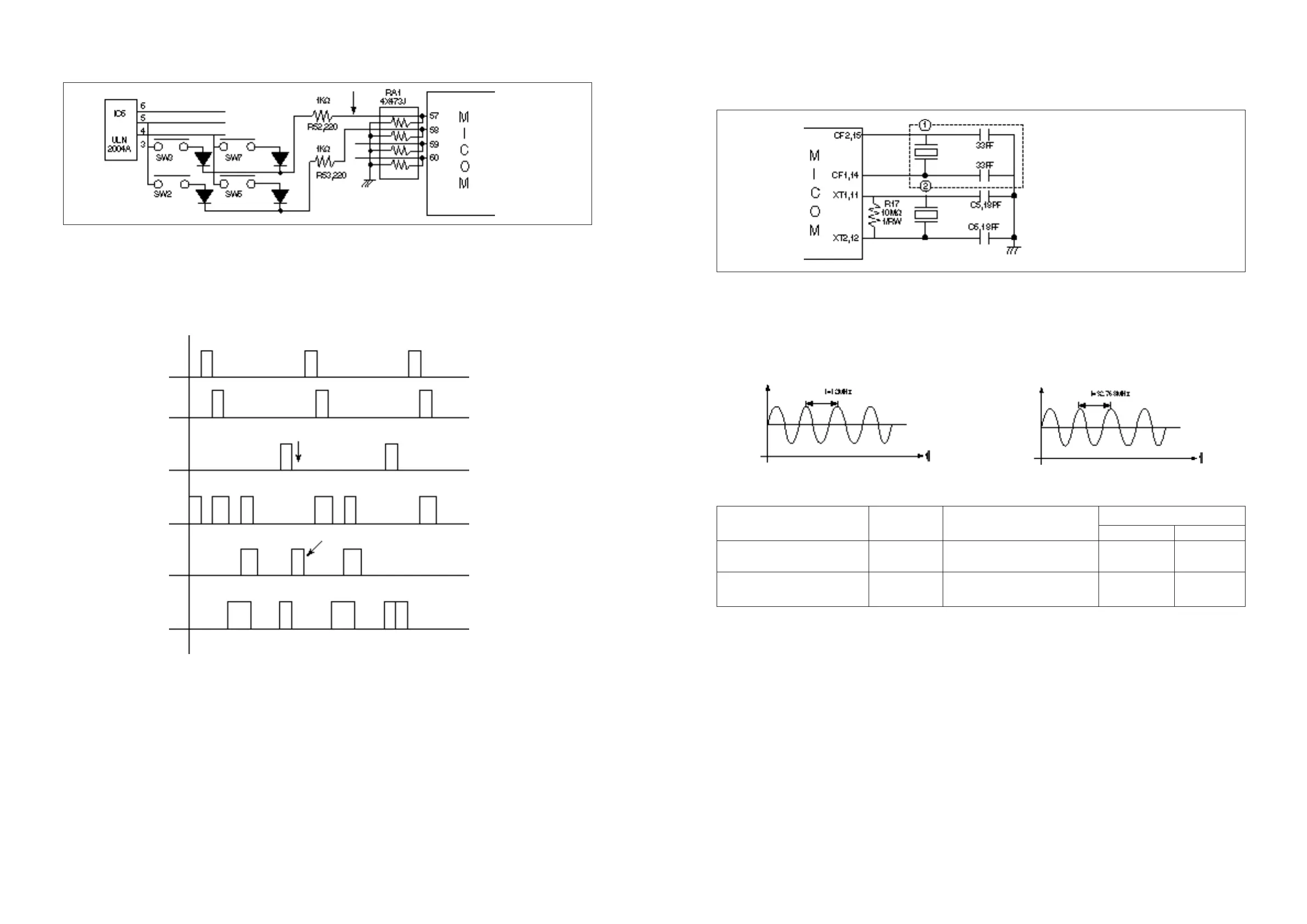

OSCILLATION UNIT

1. CIRCUIT DIAGRAM

2. EXPLANATION OF CIRCUIT

• As the OSCILLATION UNIT is a basic part of the MICOM DRIVE. If the oscillation doesn’t generate, we

able to consider that the MICOM is destroyed.

• The waveform between the part of 1 The waveform between the part of 2

and the GND and the GND

• Specification of oscillator

• It is general use for the MICOM maker’s recommendatory value of condenser which is fit for MICOM’s

characteristics.

• The R82(10MΩ, 1/6W) is in use to get rid of the initial abnormal oscillatory phenomenon of the 32.768

KHz crystal oscillator.

Murata 3 Terminal

Ceramic Resonator

(CST 12.00MTW)

Kyocera 32.768 KHz

Crystal Oscillator

(KF-38G-13P0200)

CONDENSER

TYPE OF OSCILLATOR MAKER NAME OF OSCILLATOR

C1 C2

12 MHZ

MURATA CST 12.00 MTW 33 PF 33PF

CERAMIC RESONATOR

32.768KHZ

KYOCERA KF-38G-13P0200 18PF 18PF

CRYSTAL OSCILLATOR

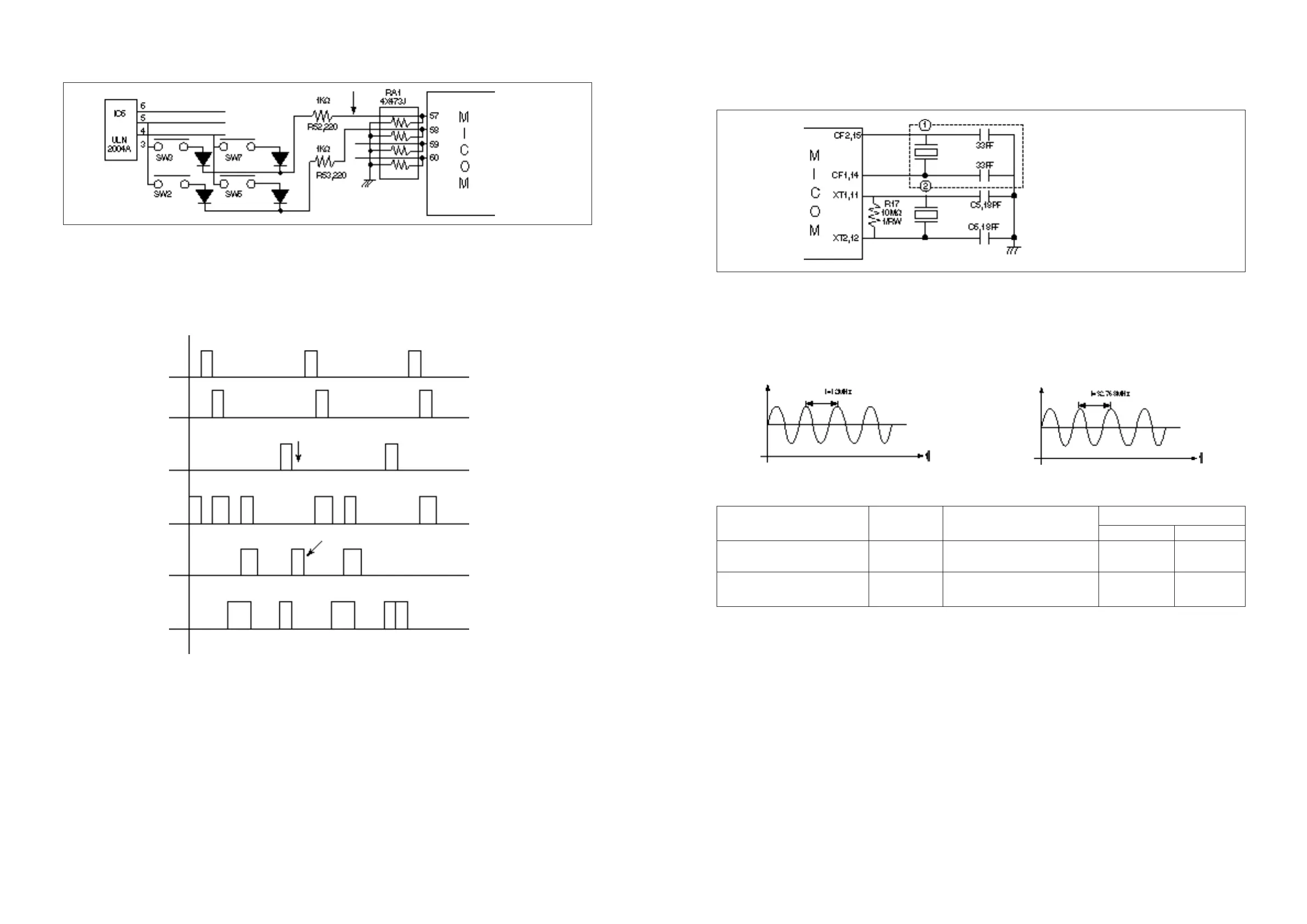

• Part of the button scan

The system of the BUTTON SCAN is in wide use for the method of the DUTY output part in L.E.D DRIVE,

yet here, it is in use for the method of the segmental output.

• Though the period of the DUTY part is 1/9, the last 9th part does not generate the waveform and checks

the button input with getting out the segmental output at the same time.

• The RA1(473J, 47KΩ) is a ‘PULL DOWN’ resistance for preventing floating action.

• The D15 prevents the L.E.D from turning on unnecessarily with forming the closed loop like a threaden

line at the time of button push.

Duty Part

Segment Part

Waveform

No Generation

Segmental Waveform

for Button Input

Loading...

Loading...