5. How To Charge R-600a Refrigerant

NO.

SVC process Image Details

1. Connect the discharging hose to

the pinch-plier

2. The outlet of discharging hose should

be placed to the outdoor(window)

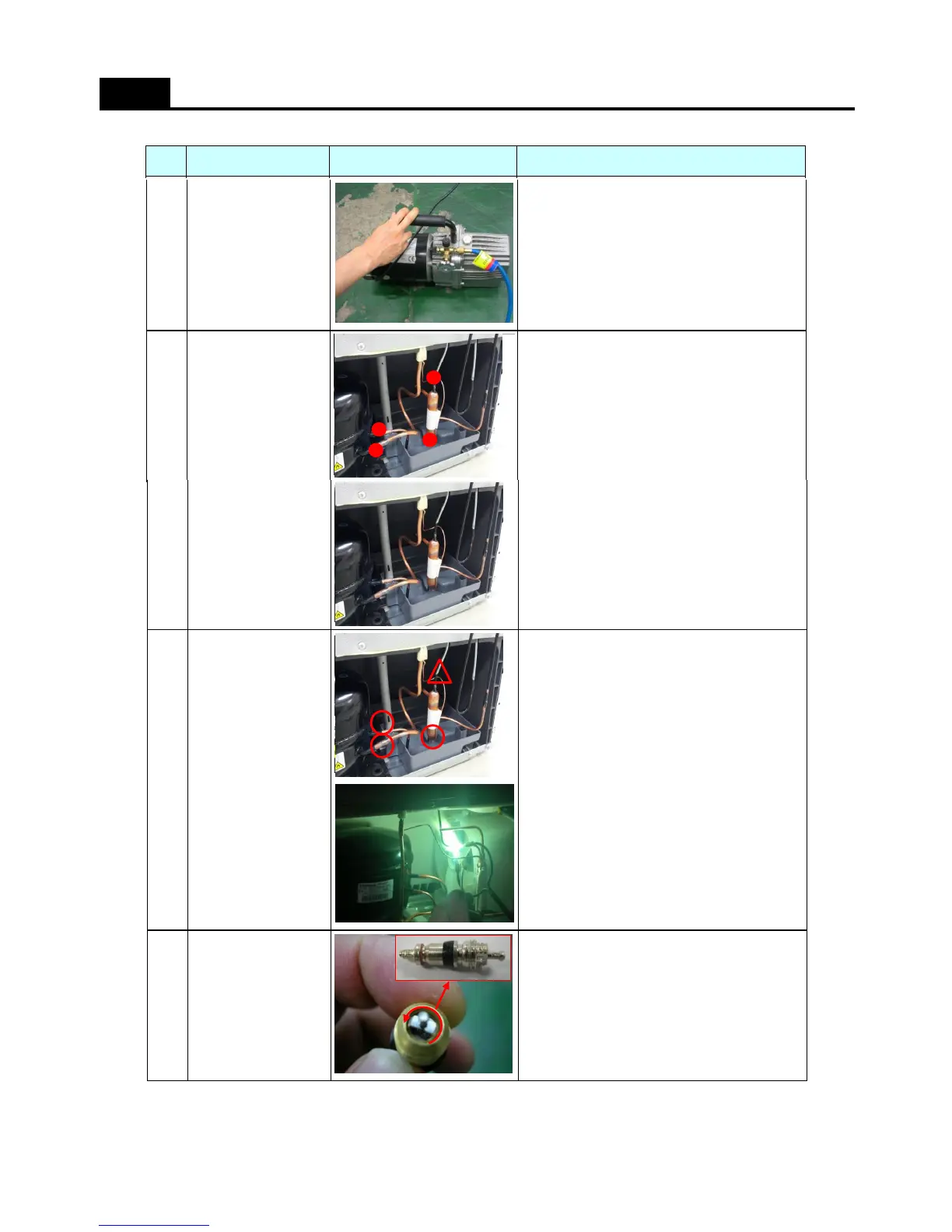

1. Fix the pinch-plier to the compressor

charging pipe.

2. Pinch-plier should not be moving freely.

※ If that is moving freely, it would cause

fire/explosion as leakage gas in the room.

1. Discharge the R-600a ref. to outdoor.

[Befor connecting the vacuum pump]

※ It should have enough time more than

1. And then, connect the vacuum pump

to the outlet of discharging hose

1. Disassembe the each pipe (Del-pipe,

Suc-pipe, Capi-pipe, Dryer & Hot-pipe)

※Vacum pump should be placed at

the outdoor where is able to clear air easily.

※ It should have enough time

more than 10 minutes to discharge.

※ Caution ; A part is easily damaged

by flame so that disassemly should

be done carefully.

Remov ing the

remaining ref.

Remov ing the

pinch-plier & pipe

Discharging

the R-600a ref.

Connecting

the

pinch-plier

&

discharging

hose

Fix ing

the pinch-plier

&

charging pipe

NO.

SVC process Image Details

1. Connect the discharging hose to

the pinch-plier

2. The outlet of discharging hose should

be placed to the outdoor(window)

1. Fix the pinch-plier to the compressor

charging pipe.

2. Pinch-plier should not be moving freely.

※ If that is moving freely, it would cause

fire/explosion as leakage gas in the room.

1. Discharge the R-600a ref. to outdoor.

[Befor connecting the vacuum pump]

※ It should have enough time more than

1. And then, connect the vacuum pump

to the outlet of discharging hose

1. Disassembe the each pipe (Del-pipe,

Suc-pipe, Capi-pipe, Dryer & Hot-pipe)

※Vacum pump should be placed at

the outdoor where is able to clear air easily.

※ It should have enough time

more than 10 minutes to discharge.

※ Caution ; A part is easily damaged

by flame so that disassemly should

be done carefully.

Remov ing the

remaining ref.

Remov ing the

pinch-plier & pipe

Discharging

the R-600a ref.

Connecting

the

pinch-plier

&

discharging

hose

Fix ing

the pinch-plier

&

charging pipe

NO.

SVC process Image Details

1. Change the comp. & dryer.

※ You should check the comp. spec.

and assemble correctly.

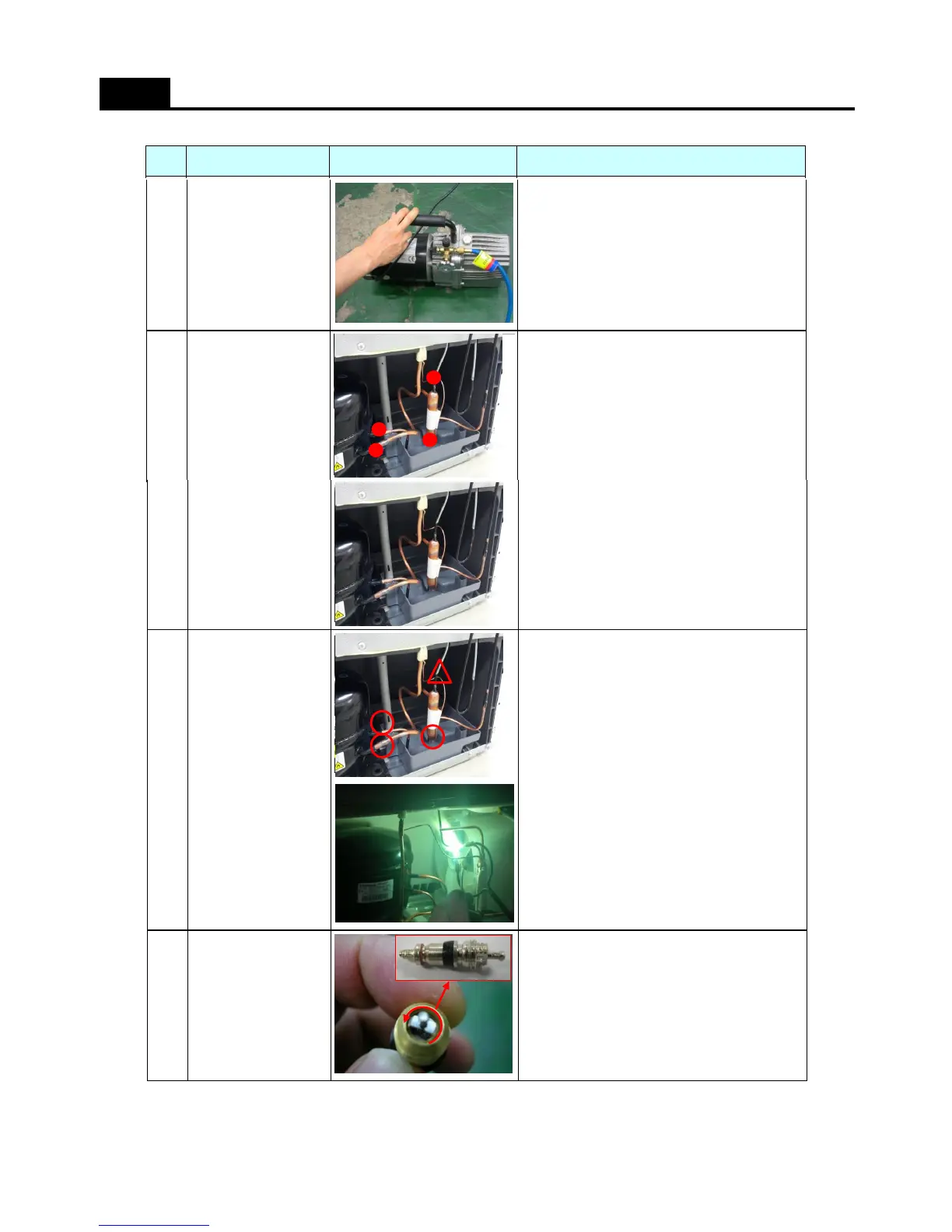

1. Weld the each pipe.

※ O Copper-Copper welding - 5% rod

△ Copper-Steel welding - 35% rod

1. Decap the couplig pipe cap and

disassemble the vlave ass'y.

※ If you don't disassemble, the coupling

rubber would be melted.

1. Weld after inserting the coupling pipe

to the compressor.

※ Use the wet cloth for preventing the

other part of machinery-room from damage.

Disassembly

of charging valv e

(Coupling pipe)

Loading...

Loading...