11 Maintenance and service

Installation manual

20

2MXM40+50A9

R32 Split series

3P600450-8T – 2022.09

11 Maintenance and service

NOTICE

General maintenance/inspection checklist. Next to the

maintenance instructions in this chapter, a general

maintenance/inspection checklist is also available on the

Daikin Business Portal (authentication required).

The general maintenance/inspection checklist is

complementary to the instructions in this chapter and can

be used as a guideline and reporting template during

maintenance.

NOTICE

Maintenance MUST be done by an authorised installer or

service agent.

We recommend performing maintenance at least once a

year. However, applicable legislation might require shorter

maintenance intervals.

NOTICE

Applicable legislation on fluorinated greenhouse gases

requires that the refrigerant charge of the unit is indicated

both in weight and CO

2

equivalent.

Formula to calculate the quantity in CO

2

equivalent

tonnes: GWP value of the refrigerant × total refrigerant

charge [in kg] / 1000

12 Disposal

NOTICE

Do NOT try to dismantle the system yourself: dismantling

of the system, treatment of the refrigerant, oil and other

parts MUST comply with applicable legislation. Units

MUST be treated at a specialised treatment facility for

reuse, recycling and recovery.

INFORMATION

To protect the environment, make sure to perform an

automatic pump down operation when relocating or

dismantling the unit. For the pump down procedure, refer

to the service manual or the installer reference guide.

13 Technical data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

13.1 Wiring diagram

The wiring diagram is delivered with the unit, located inside of

the outdoor unit (bottom side of the top plate).

13.1.1 Unified wiring diagram legend

For applied parts and numbering, refer to the wiring diagram on the

unit. Part numbering is by Arabic numbers in ascending order for

each part and is represented in the overview below by "*" in the part

code.

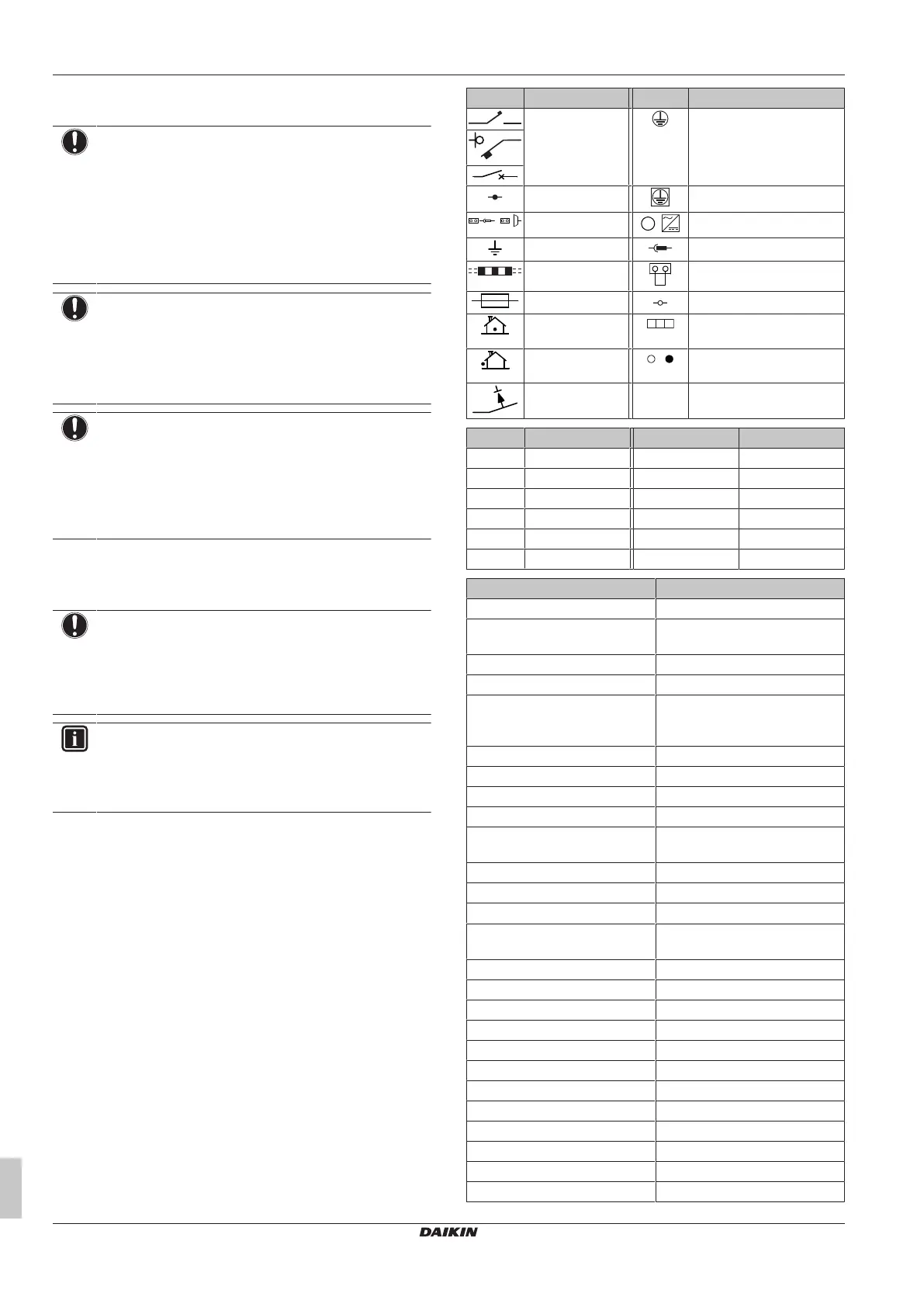

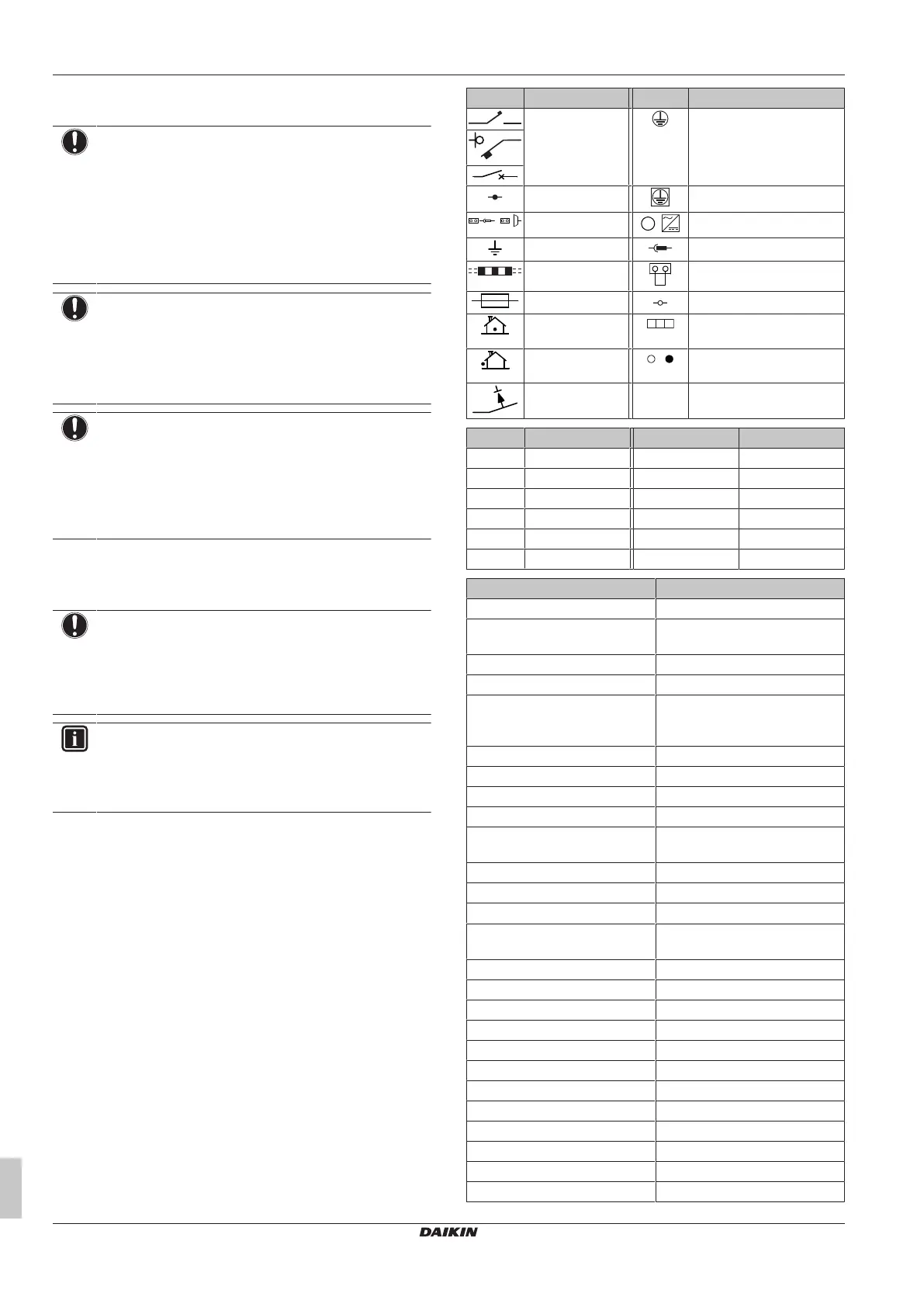

Symbol Meaning Symbol Meaning

Circuit breaker Protective earth

Connection Protective earth (screw)

Connector

,

Rectifier

Earth Relay connector

Field wiring Short-circuit connector

Fuse Terminal

Indoor unit Terminal strip

Outdoor unit Wire clamp

Residual current

device

Symbol Colour Symbol Colour

BLK Black ORG Orange

BLU Blue PNK Pink

BRN Brown PRP, PPL Purple

GRN Green RED Red

GRY Grey WHT White

SKY BLU Sky blue YLW Yellow

Symbol Meaning

A*P Printed circuit board

BS* Pushbutton ON/OFF, operation

switch

BZ, H*O Buzzer

C* Capacitor

AC*, CN*, E*, HA*, HE*, HL*,

HN*, HR*, MR*_A, MR*_B, S*, U,

V, W, X*A, K*R_*, NE

Connection, connector

D*, V*D Diode

DB* Diode bridge

DS* DIP switch

E*H Heater

FU*, F*U, (for characteristics,

refer to PCB inside your unit)

Fuse

FG* Connector (frame ground)

H* Harness

H*P, LED*, V*L Pilot lamp, light emitting diode

HAP Light emitting diode (service

monitor green)

HIGH VOLTAGE High voltage

IES Intelligent eye sensor

IPM* Intelligent power module

K*R, KCR, KFR, KHuR, K*M Magnetic relay

L Live

L* Coil

L*R Reactor

M* Stepper motor

M*C Compressor motor

M*F Fan motor

M*P Drain pump motor

M*S Swing motor

Loading...

Loading...