SERVICING

32

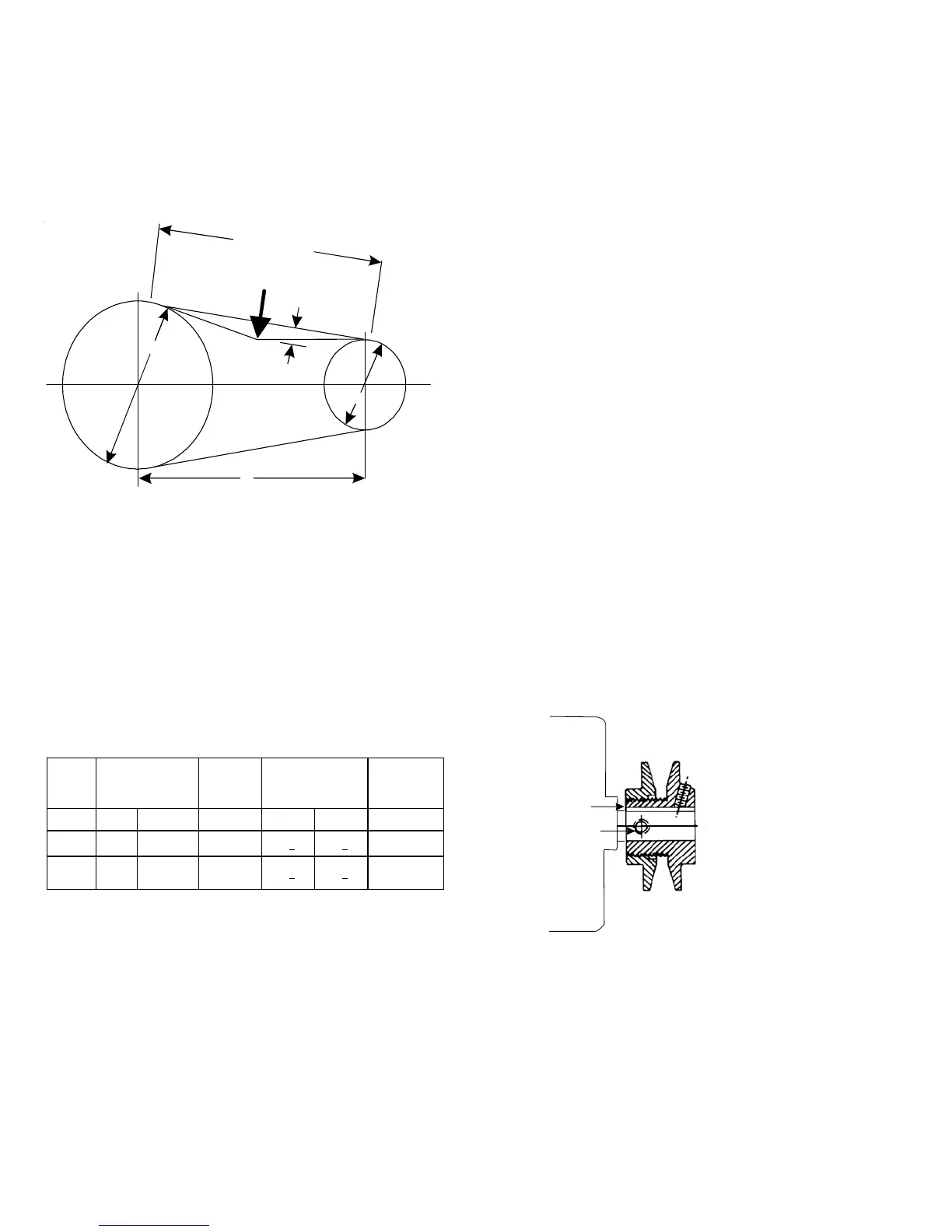

between the minimum and maximum force. To determine the

deflection distance from the normal position, use a straight-

edge or stretch a cord from sheave to sheave to use as a

reference line. On multiple belt drives, an adjacent undeflected

belt can be used as a reference.

S

P

A

N

L

E

N

G

T

H

t

*

D

E

F

L

E

C

T

I

O

N

F

O

R

C

E

h

C

d

H

D

*Apply force to the center of the span.

t = Span length, inches

C = Center distance, inches

D = Larger sheave diameter, inches

d = Smaller sheave diameter, inches

h = Deflection height, inches

DRIVE BELT TENSION ADJUSTMENT

15&20 TON MODELS

MODEL

SHEAVE

DIAMETER

(in)

DEFLECTION

(in)

BELT DRIVE Used New

15 Ton B, BA Standard 4.3 to 5.5 5.5 +

.5 8.2 + .5 1/4 ± 1/16

20 Ton

25 Ton

B, BA Standard 4.3 to 5.5 5.5 +

.5 8.2 + .5 1/4 ± 1/16

DEFLECTION

FORCE (lbs)

TYPE

RECOMMENDED POUNDS OF FORCE PER BELT

S-206 INDOOR FAN ROTATION CHECK

Evaporator Fan Rotation Check (Three Phase Models

Only)

Check that fan rotates clockwise when viewed from the drive

side of unit and in accordance with rotation arrow shown on

blower housing. If it does not, reverse any two incoming

power cables at Single Point Power Block. In this case,

repeat bearing check.

Do not attempt to change load side wiring. Internal wiring

assures all motors and compressors will rotate in correct

direction once evaporator fan motor rotation check has been

made.

S-207 MOTOR SHEAVE ADJUSTMENTS

V

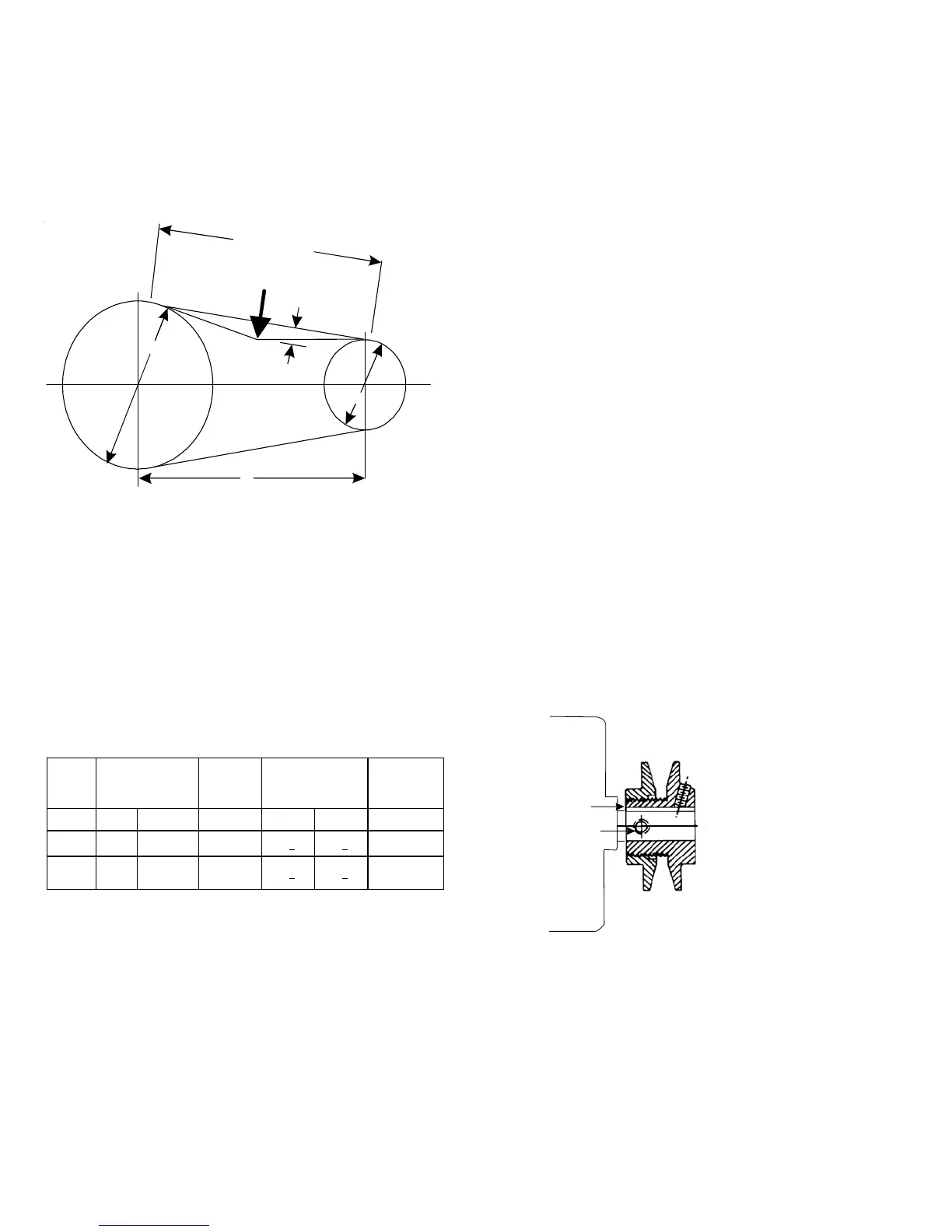

L, VM & 2VP VARIABLE PITCH KEY TYPE MOTOR

SHEAVES

The driving and driven motor sheaves should be in alignment

with each other and the shafts parallel.

VL & VM SHEAVES ADJUSTMENT

1. Loosen set screw “B” using a 5/32" Allen key.

2. Making half or full turns from closed position, adjust

sheave pitch diameter for desired speed. DO NOT OPEN

MORE THAN SIX FULL TURNS.

3. Tighten set screw “B” securely over flat.

4. Carefully put on belts and adjust belt tension. DO NOT

FORCE BELTS OVER GROOVES.

5. Ensure all keys are in place and the set screws tight

before starting drive. Recheck set screws and belt

tension after 24 hours service.

NOTE: Future adjustments should be made by loosening

the belt tension and increasing or decreasing the pitch

diameter of the sheave by half or full turns as required.

Readjust belt tension before starting drive.

C

B

VL & VM

NOTE: Do not operate sheave with flange projecting

beyond the hub end.

Loading...

Loading...