29

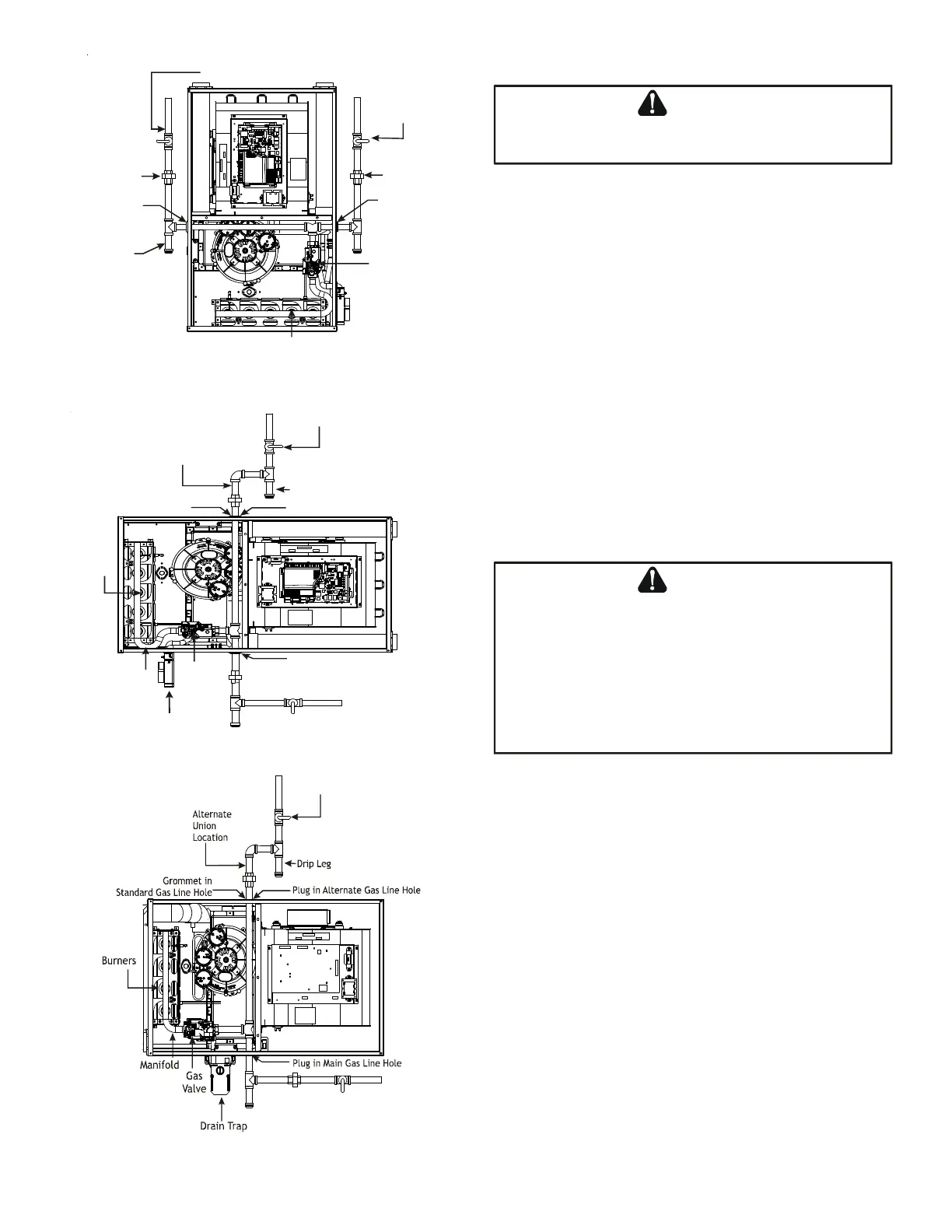

Alternate

Gas Line

Location

Plug in

Alternate

Gas Line

Hole

Gas Valve

Burners

Manual Shut Off Valve

(upstream from ground joint pipe union)

Drip Leg

Grommet

in Standard

Gas Line

Hole

*Ground

Joint

Pipe Union

*Ground

Joint

Pipe Union

*NOTE: Union may be inside furnace cabinet where allowed by local codes.

COUNTERFLOW - Figure 38

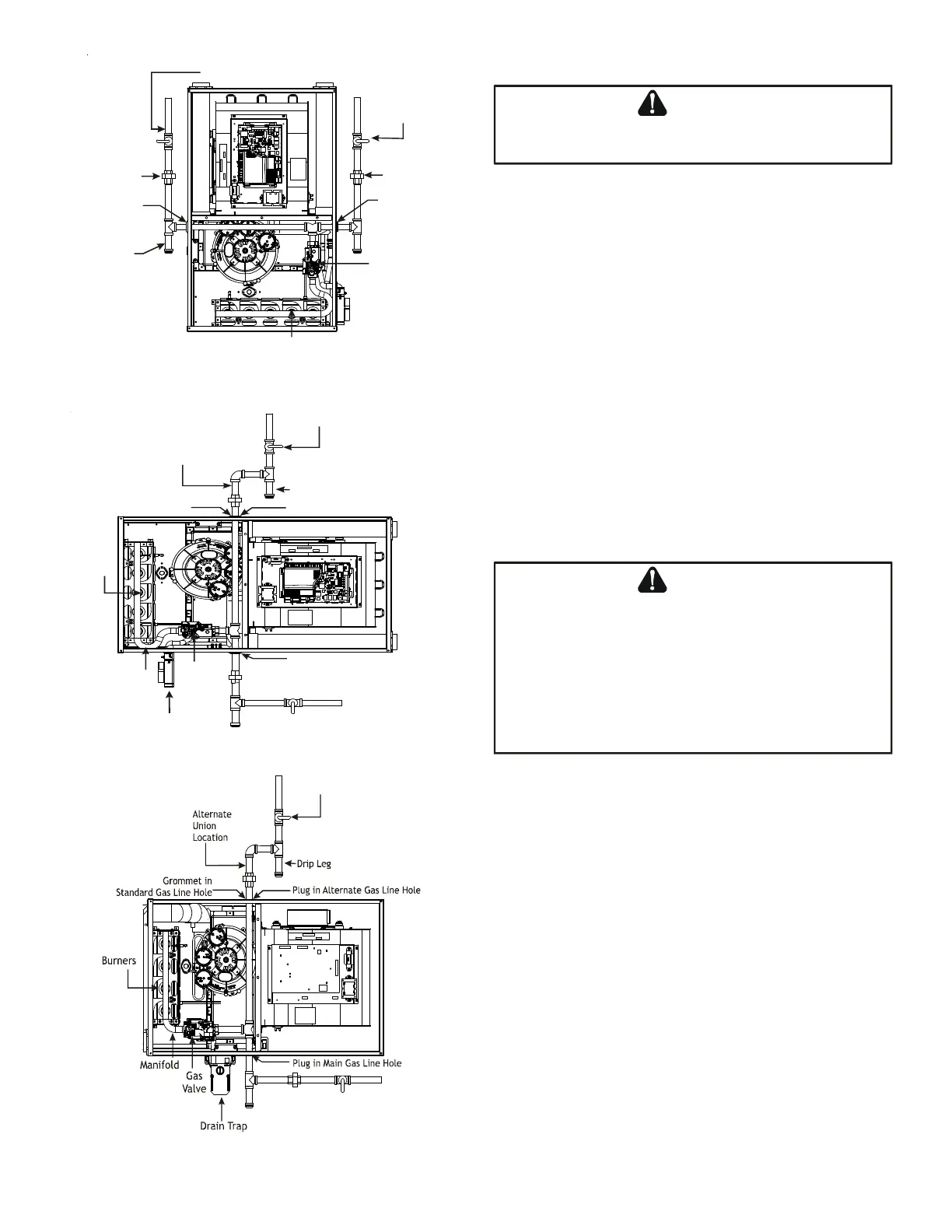

Drip Leg

Plug in Main Gas Line Hole

Alternate

Union

Location

Manual Shut Off Valve

(upstream from

ground joint pipe union)

Gas

Valve

Burners

Drain Trap

Manifold

Plug in Alternate Gas Line Hole

Grommet in

Standard Gas Line Hole

UPFLOW - HORIZONTAL LEFT - Figure 39

Manual Shut Off Valve

(upstream from

ground joint

pipe union)

COUNTERFLOW - HORIZONTAL RIGHT - Figure 40

GAS PIPING CHECKS

T

O

AVOID

THE

POSSIBILITY

OF

EXPLOSION

OR

FIRE

,

NEVER

USE

A

MATCH

OR

OPEN

FLAME

TO

TEST

FOR

LEAKS

.

WARNING

Before placing unit in operation, leak test the unit and gas

connections.

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector, or

other approved testing methods.

NOTE: Never exceed specified pressures for testing.

Higher pressure may damage the gas valve and cause

subsequent overfiring, resulting in heat exchanger

failure.

Disconnect this unit and shutoff valve from the gas supply

piping system before pressure testing the supply piping

system with pressures in excess of 1/2 psig (3.48 kPa).

Isolate this unit from the gas supply piping system by closing

its external manual gas shutoff valve before pressure testing

supply piping system with test pressures equal to or less

than 1/2 psig (3.48 kPA).

PROPANE GAS TANKS AND PIPING

I

F

THE

GAS

FURNACE

IS

INSTALLED

IN

A

BASEMENT

,

AN

EXCAVATED

AREA

OR

CONFINED

SPACE

,

IT

IS

STRONGLY

RECOMMENDED

TO

CONTACT

A

PROPANE

SUPPLIER

TO

INSTALL

A

GAS

DETECTING

WARNING

DEVICE

IN

CASE

OF

A

GAS

LEAK

.

S

INCE

PROPANE

GAS

IS

HEAVIER

THAN

AIR

,

ANY

LEAKING

GAS

CAN

SETTLE

IN

ANY

LOW

AREAS

OR

CONFINED

SPACES

.

P

ROPANE

GAS

ODORANT

MAY

FADE

,

MAKING

THE

GAS

UNDETECTABLE

EXCEPT

WITH

A

WARNING

DEVICE

.

•

•

WARNING

A gas detecting warning system is the only reliable way to

detect a propane gas leak. Rust can reduce the level of

odorant in propane gas. Do not rely on your sense of smell.

Contact a local propane gas supplier about installing a gas

detecting warning system. If the presence of gas is

suspected, follow the instructions listed in the Safety

Considerations section of this manual.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters, NBFU

Manual 58.

CANADA: National Standard of Canada, Natural Gas and

Propane Installation Code (NSCNGPIC) CAN/CSA B149.1-15

For satisfactory operation, propane gas pressure must be

10” WC at the furnace manifold with all gas appliances in

operation. Maintaining proper gas pressure depends on three

main factors:

1. Vaporization rate, depending on temperature of the

liquid, and “wetted surface” area of the container or

containers.

Loading...

Loading...