Do you have a question about the Daikin ECORICH EHU 40 Series and is the answer not in the manual?

Defines safety levels (DANGER, WARNING, CAUTION) and their implications.

Important usage notes and disclaimers regarding product operation and manufacturer responsibility.

Prohibits use in critical applications and outlines essential precautions.

Key procedures and warnings for safe installation, wiring, and operation.

Highlights the energy efficiency achieved through the IPM motor drive system.

Explains how to interpret model numbers and unit/controller options.

Comprehensive table detailing electrical and hydraulic specifications for each model.

Specifies suitable hydraulic oils, ambient conditions, and installation requirements.

Visual representation of performance curves relating pressure and flow rate.

Provides detailed drawings and dimensions for physical installation.

Illustrates the internal layout and flow of the hydraulic system.

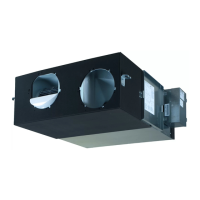

Visual guide to the main parts and components of the hydraulic unit.

Outlines the sequential steps for initial product setup and commissioning.

Ensures all delivered items match the packing list.

Confirms the product's model number matches the order.

Safe methods for lifting, moving, and transporting the unit.

Guidance on unit placement, securing, and ventilation for installation.

Details port specifications and recommended practices for hydraulic hose connections.

Step-by-step guide for correctly filling the hydraulic oil tank.

Instructions for reattaching the unit's exterior cover after electrical work.

Overview of electrical connections, wiring diagrams, and breaker requirements.

Guidelines for connecting the main power supply, including cable and terminal details.

Procedures for connecting external control and signal cables to the unit.

Essential procedures for initial operation checks, flushing, and bleeding.

Identifies panel elements and describes mode switching.

Explains the display indications in the normal operating mode.

Guide to navigating and viewing operational data in monitor mode.

Instructions for adjusting parameters and settings via the control panel.

How to access and interpret alarm history and codes.

A comprehensive reference of all adjustable parameters, their functions, and settings.

Configuration of the effective logic for digital input signals controlling ON/OFF.

Setting target pressure (PL0) and flow rate (QL0) values.

Customizing digital outputs and alarm relay notification behavior.

Parameters for the internal pressure switch actuation and indication.

Configuration options for preventing errors like dry running and overheating.

Settings for fan speed, surge suppression, and rotation warning delays.

Detailed guide to identifying and resolving unit alarms.

Troubleshooting steps for various warning conditions.

Recommended regular checks and maintenance tasks.

General instructions for cleaning components and replacing worn parts.

Specific procedures for servicing the oil cooler unit.

Steps for cleaning and maintaining the oil filler port air breather.

Instructions for cleaning the hydraulic oil suction strainer.

Procedures for readjusting the high-pressure safety valve as needed.

Guide for installing the optional fixed throttle for pressure stability.

Procedure to set the minimum operational speed for the motor.

Visual timelines illustrating signal behavior during system startup.

Overview of the PC software for monitoring and controlling the hybrid system.

| Brand | Daikin |

|---|---|

| Model | ECORICH EHU 40 Series |

| Category | Industrial Equipment |

| Language | English |